Economic inorganic-organic composite flocculant

A kind of composite flocculant, economical technology, applied in the field of water treatment, can solve the problems of retention, low occupancy, etc., achieve the effect of low cost, low moisture content, and benefit for subsequent treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

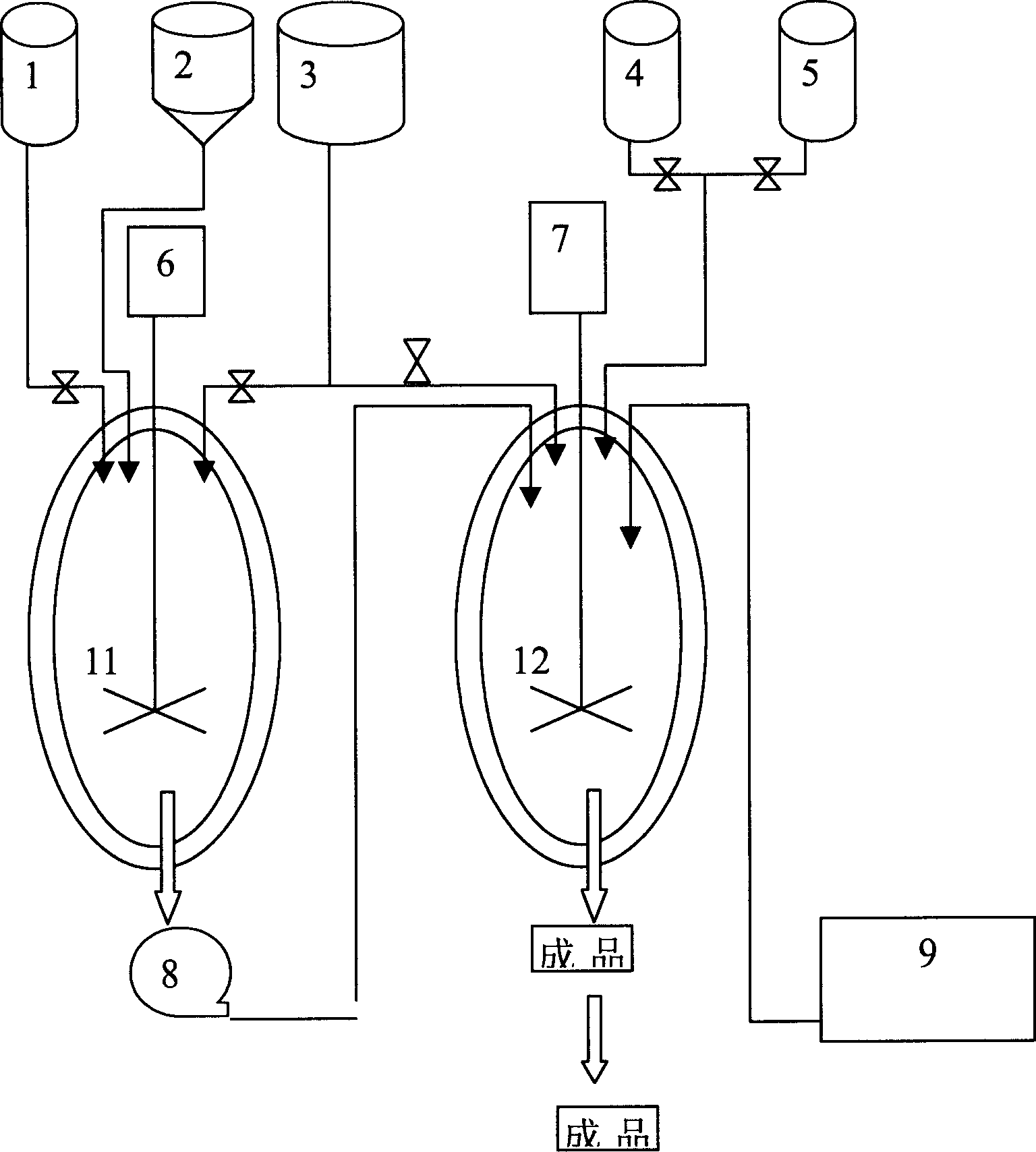

Method used

Image

Examples

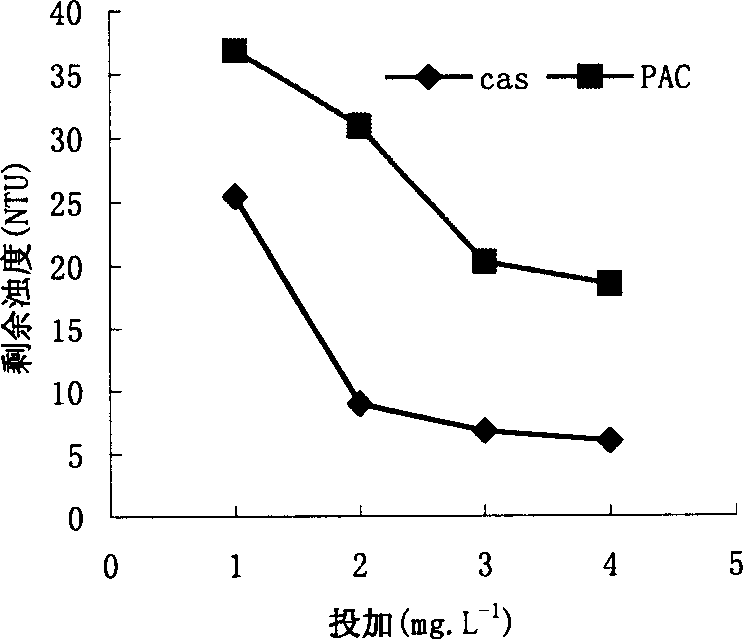

Embodiment 1

[0040] The present invention takes inorganic aluminum salt (aluminum trichloride), corn starch, water, sodium hydroxide (NaOH) as raw material, and corn starch is main component, and water is used as reaction solvent, and sodium hydroxide is used for the modification of corn starch; The mass ratio of aluminum and cornstarch in the salt is 1:1;

[0041] Its preparation method is: (1) modification of starch: take 20 grams of corn starch and add 250% water to form a solution, slowly add 20 ml of 25% NaOH in a water bath at 55 ° C and slowly stir for modification reaction for 1 hour; (2) take trichloro 100 grams of aluminum chloride, containing 20 grams of aluminum, add 110 grams of water; (3) synthesis reaction: under stirring conditions, add modified starch to the aluminum chloride solution to mix, adjust the pH to 2.5 with hydrochloric acid and caustic soda solution, and Composite reaction in a water bath at 55°C for 3 hours to obtain an emulsion, which is the product flocculan...

Embodiment 2

[0043] The difference from Example 1 is that the inorganic salt is an iron salt, the ratio of iron to starch is 1:1 in the preparation process, and the pH in the synthesis reaction is different. Its preparation method is: (1) take 45 grams of ferric trichloride, which contains 15 grams of iron, and add 70 grams of water to make a solution; (2) modification of starch: take 10 grams of cornstarch and add 190 grams of water to make a solution, Slowly add 5mL 50% NaOH in a water bath at 40°C and stir the modification reaction for 1 hour; (3) Composite reaction: fully mix the modified starch and iron salt, adjust the pH to 1.0, and compound at 60°C under stirring conditions React for 6 hours to get the product flocculant;

Embodiment 3

[0045] Difference with Example 2 is: the mass ratio of iron and cornstarch in the iron salt is 10: 1; Its preparation method is: (1) the preparation of iron salt: get 100 grams of iron powders by mass ratio and use 20%HCl to completely After dissolving, use an oxidizing agent (chlorine, hydrogen peroxide, etc.) to make a solution containing ferric iron; (2) Modification of starch: take 10 grams of cornstarch and add 50 grams of water to make a solution, slowly add 10 mL of 10% KOH stirred modification reaction for 0.5 hours; (3) Composite reaction: Add the modified starch into the iron salt solution under agitation, adjust the pH to 1.5, and perform a composite reaction at 80°C for 3 hours under agitation to obtain The reddish-brown emulsion is the product flocculant;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com