Method for recycling nickel, buffer salt and water from chemical nickel-plating ageing solution

A technology of electroless nickel plating and aging solution, applied in chemical instruments and methods, liquid chemical plating, inorganic chemistry, etc., can solve environmental pollution and other problems, and achieve the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

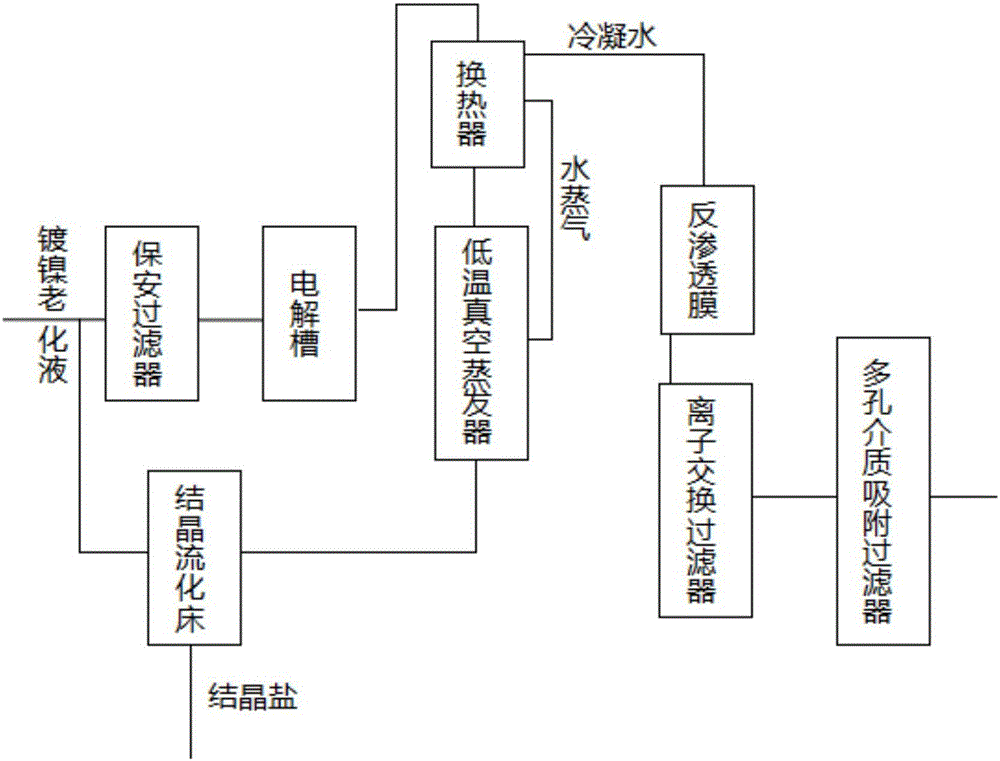

Image

Examples

Embodiment 1

[0023] A method for reclaiming nickel, buffer salt and water from electroless nickel plating aging solution, comprising the following steps:

[0024] 1) Filter the aging solution through a filter, the filter aperture of the security filter is 0.5um, and the water inlet flow rate is 2.5m 3 / h, the security filter also includes a reverse osmosis flushing system, which automatically flushes once every 4 hours, the flushing time is 30s, and the hydraulic flushing flow rate is 8m 3 / h;

[0025] 2) The electroless nickel plating aging solution is electrolytically treated by an electrolytic cell. The electrolytic cell uses nickel foam as the cathode and a titanium-ruthenium mesh electrode as the anode. The reaction voltage is 20V, the current is 15A, and the reaction time is 1 hour. The electrolytic method can Ni in aging solution 2+ The ion concentration is reduced from 2g / L to 50mg / L; the organic matter and complexing agent in the aging solution are oxidized and broken at the ano...

Embodiment 2

[0031] A method for reclaiming nickel, buffer salt and water from electroless nickel plating aging solution, comprising the following steps:

[0032] 1) Filter the aging solution through a filter, the filter aperture of the security filter is 2um, and the water inlet flow rate is 3.7m 3 / h, the security filter also includes a reverse osmosis flushing system, which automatically flushes once every 4 hours, the flushing time is 30s, and the hydraulic flushing flow rate is 8m 3 / h;

[0033]2) The electroless nickel plating aging solution is electrolytically treated by an electrolytic cell. The electrolytic cell uses nickel foam as a cathode and a titanium-ruthenium mesh electrode as an anode. The reaction voltage is 85V, the current is 42A, and the reaction time is 1.5 hours. The electrolytic method can Ni in aging solution 2+ The ion concentration is reduced from 2g / L to 50mg / L; the organic matter and complexing agent in the aging solution are oxidized and broken at the anode ...

Embodiment 3

[0039] A method for reclaiming nickel, buffer salt and water from electroless nickel plating aging solution, comprising the following steps:

[0040] 1) Filter the aging solution through a filter, the filter aperture of the security filter is 3.5um, and the water flow rate is 5m 3 / h, the security filter also includes a reverse osmosis flushing system, which automatically flushes once every 4 hours, the flushing time is 30s, and the hydraulic flushing flow rate is 8m 3 / h;

[0041] 2) The electroless nickel plating aging solution is electrolytically treated by an electrolytic cell. The electrolytic cell uses nickel foam as a cathode and a titanium-ruthenium mesh electrode as an anode. The reaction voltage is 150V, the current is 70A, and the reaction time is 2 hours. The electrolytic method can Ni in aging solution 2+ The ion concentration is reduced from 2g / L to 50mg / L; the organic matter and complexing agent in the aging solution are oxidized and broken at the anode to rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com