A kind of preparation method of porcine lung protein peptide

A porcine lung protein peptide and pig lung technology, which is applied in the field of porcine lung protein peptide preparation, can solve the problems of waste liquid not being fully utilized, and achieve the effects of improving utilization value, improving immunity, and being easy to absorb

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The invention provides a preparation method of porcine lung protein peptide, which uses the waste liquid after extracting heparin sodium from pig lung as raw material, adopts modern biological technologies such as resin desalination, enzymatic hydrolysis, ultrafiltration membrane separation, spray drying, etc. to obtain porcine lung protein peptide.

[0040] The preparation method of porcine lung protein peptide of the present invention comprises the steps:

[0041] (a) Desalting: After filtering the waste liquid after extracting heparin sodium from pig lung, desalting through resin adsorption to obtain filtrate I;

[0042] (b) enzymolysis: adding protease to the filtrate I to carry out enzymolysis reaction to obtain enzymolysis solution II;

[0043] (c) ultrafiltration membrane separation: the enzymolysis solution II is separated by ultrafiltration membrane to obtain filtrate III;

[0044] (d) drying: drying the filtrate III to obtain the porcine lung protein peptide...

Embodiment 1

[0077] Preparation of porcine lung protein peptide products

[0078] Step 1: Remove the hose and clean the pig lungs

[0079] Take 550kg pig lungs, remove the hose mechanically, wash and decontaminate with clean water, and crush them at high speed.

[0080] Step 2: Salt solution

[0081] Add 500 kg of purified water to the pulverized pig lungs, add 5% (w / w) sodium chloride, and extract for 1 hour at room temperature to facilitate the extraction of heparin.

[0082] Step 3: Compound enzyme enzymatic hydrolysis

[0083] Add animal proteolytic enzyme (purchased from Guangxi Donghenghuadao Biotechnology Co., Ltd., it is a compound enzyme, composed of papain, neutral protease, and alkaline protease in a ratio of 1:2:2), and the amount added is pig 2% of the lung mass was reacted at 50° C. for 10 hours. After the enzymatic hydrolysis reaction, the solution was heated to 85° C. and kept for 30 minutes to inactivate the enzyme in the solution.

[0084] Step 4: Resin Adsorption

...

Embodiment 2

[0099] Preparation of porcine lung protein peptide products

[0100] Step 1: Resin Adsorption

[0101] The porcine lung protein liquid after extracting heparin sodium 10m 3 Filtered through 80 mesh sieve to obtain 9.2m 3 Permeate. Add 92 kg of ion exchange resin 703 (D311) to the permeate and react for 12 hours to obtain 9.0m 3 Filtrate I.

[0102] Step 2: Alkaline protease hydrolysis

[0103] Add 46 kg of alkaline protease (2709 alkaline protease, enzyme activity: 200,000 IU, purchased from Nanning Pangbo Bioengineering Co., Ltd.) to filtrate I, and enzymolyze at 55°C for 6 hours to obtain solution II.

[0104] Step 3: Ultrafiltration Membrane Separation

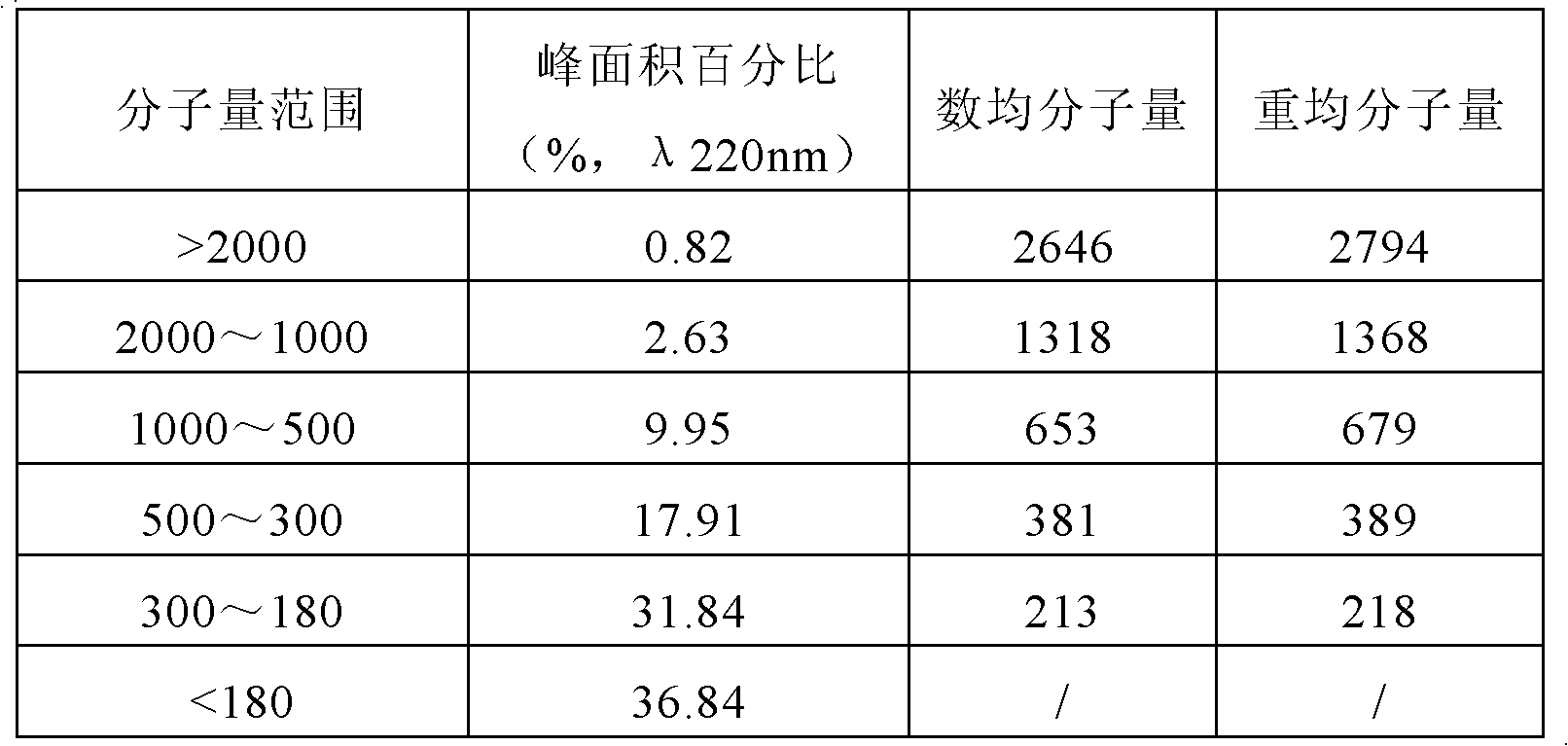

[0105] The obtained solution II is separated through an ultrafiltration membrane with a molecular weight of 1000 Da to obtain a filtrate III, and the filtrate III enters the next process link. Use the retentate that has not passed the ultrafiltration membrane with a molecular weight of 1000Da for other purposes; or p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com