Electrolyte used for waste lithium battery discharge, and waste lithium battery discharge method

A waste lithium battery and electrolyte technology, applied in the field of electrolyte, can solve the problems of unfeasible large-scale discharge, overheating, corrosion of electrodes, etc., to solve polarization and pollution of reaction products, promote anode reaction, and achieve high reaction speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

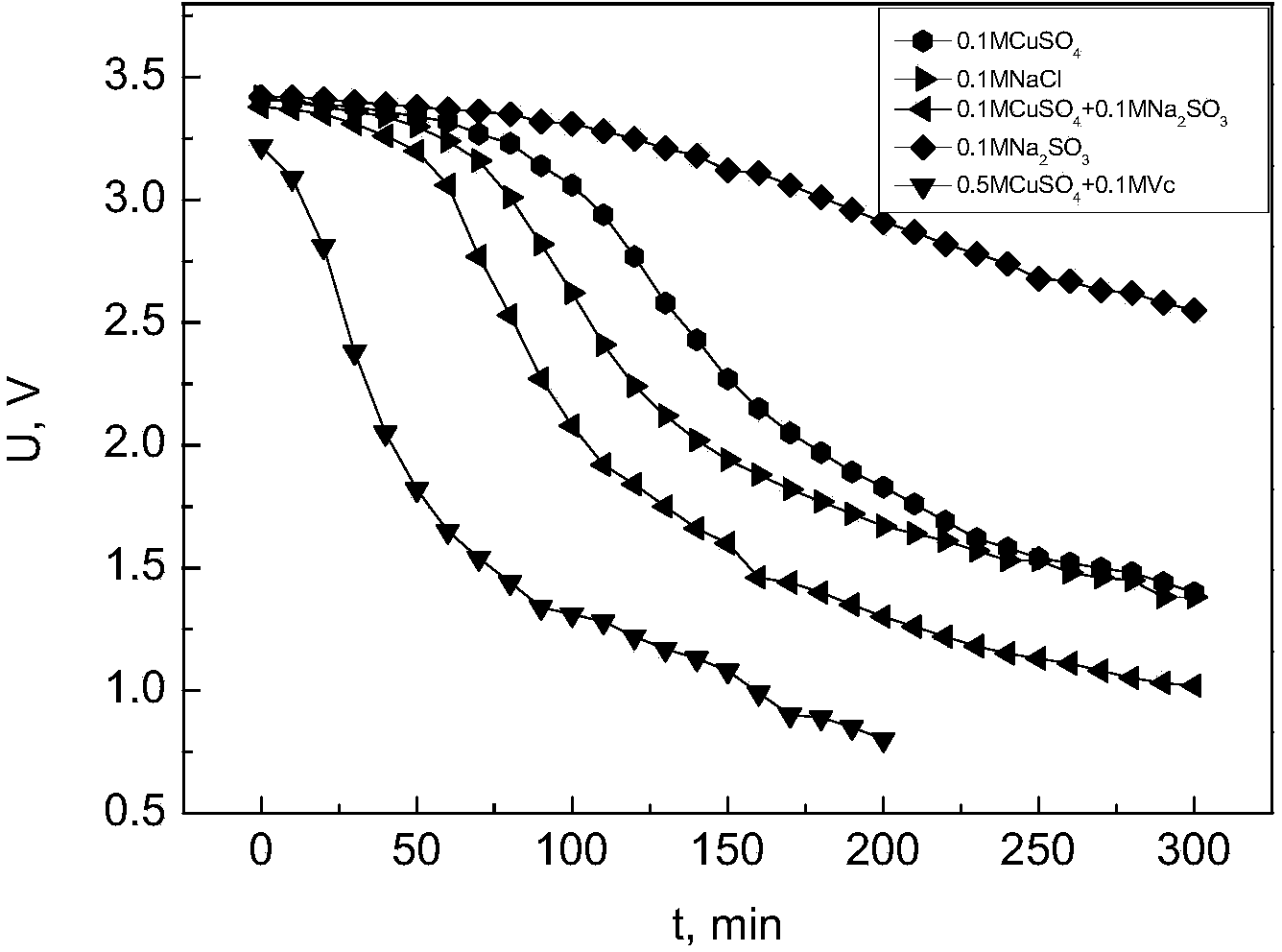

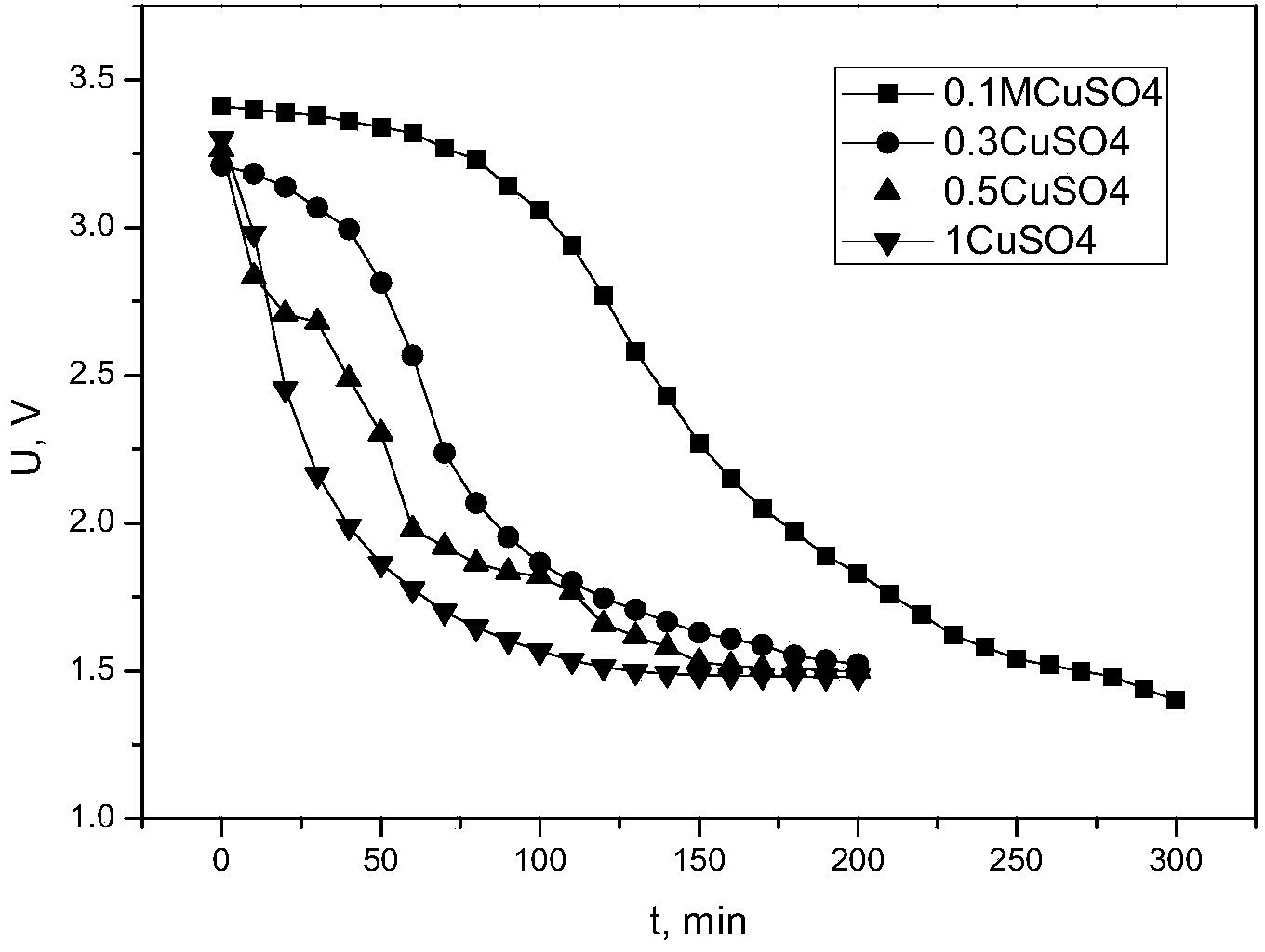

[0023] A kind of electrolytic solution that is used for the discharge of waste lithium ion battery, CuSO in the described electrolytic solution 4 The concentration is 0.1mol / L.

[0024] When investigating the discharge of the electrolyte, a laboratory test method was adopted, including the following steps:

[0025] Lead out the positive and negative poles of the waste lithium-ion battery with wires, and connect them to the nickel sheets respectively, then put the nickel sheets into the above-mentioned electrolyte, and then measure the current and (or) voltage changes with time during the battery discharge process, At the same time, observe the changes on the surface of the positive and negative nickel sheets in the electrolyte until the current and voltage tend to be stable, then the discharge ends.

Embodiment 2

[0027] A kind of electrolytic solution that is used for the discharge of waste lithium ion battery, CuSO in the described electrolytic solution 4 The concentration is 0.3mol / L;

[0028] A method for safely discharging waste lithium-ion batteries, please refer to Example 1.

Embodiment 3

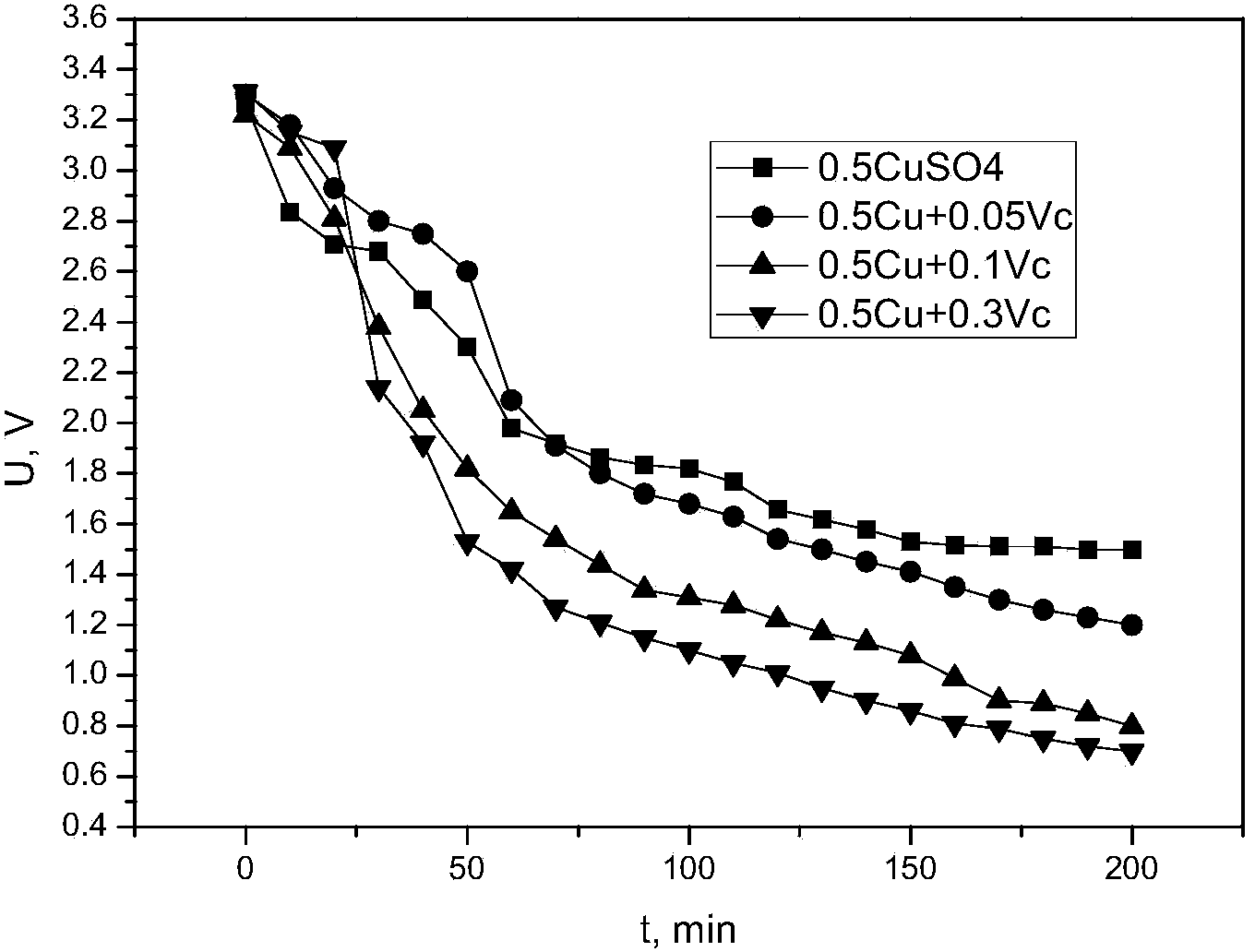

[0030] A kind of electrolytic solution that is used for the discharge of waste lithium ion battery, CuSO in the described electrolytic solution 4 The concentration is 0.5mol / L;

[0031] A method for safely discharging waste lithium-ion batteries, please refer to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com