Resourceful comprehensive utilization method of waste printed circuit boards

A printed circuit board and resource-based technology, applied in the field of comprehensive utilization of resources, can solve problems such as harsh operating environment, high local temperature, and high environmental protection requirements, and achieve the effects of solving environmental pollution, realizing industrialization, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

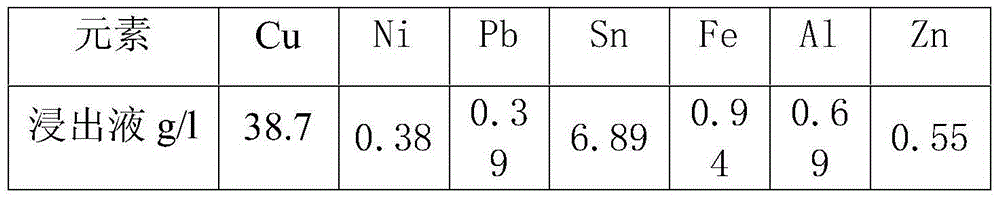

Embodiment 1

[0026] Centrifugal rotating heating equipment is used to remove the components on the discarded circuit boards and recover them into solder, components and substrates respectively. The solder is packaged and sold directly, and the components are tested according to relevant standards and sold separately. If the components fail to meet the standards, they may be broken together with the substrate. The substrate is firstly crushed by impact shearing, and the particle size is below 20mm. After secondary crushing, the particle size is below 3mm. The crushed substrate and components are magnetically separated to separate ferrous materials and non-ferrous materials. Materials, after the non-ferrous materials are sorted by eddy current to separate aluminum, they enter the three-stage fine grinding of the hammer mill to make the particle size below 0.6mm, and the finely ground materials enter the high-voltage electrostatic separator to separate the metal materials and non-ferrous mater...

Embodiment 2

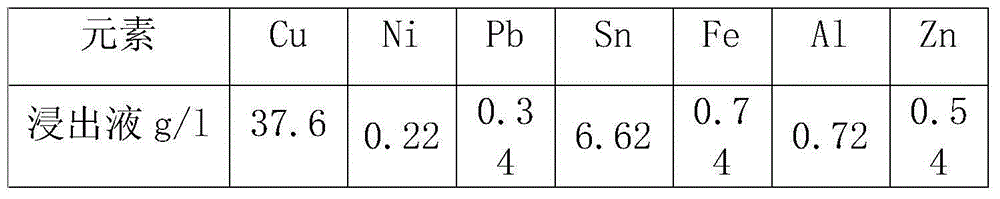

[0051] Centrifugal rotating heating equipment is used to remove the components on the discarded circuit boards and recover them into solder, components and substrates respectively. The solder is packaged and sold directly, and the components are tested according to relevant standards and sold separately. If the components fail to meet the standards, they may be broken together with the substrate. The substrate is firstly crushed by impact shearing, and the particle size is below 20mm. After secondary crushing, the particle size is below 3mm. At this time, the magnetic substance (Fe) is separated from the non-magnetic substance by a magnetic separator, and the iron is separated. Iron and non-ferrous materials, non-ferrous materials are separated by eddy current separation to remove aluminum, and after removing iron and aluminum, the materials are subjected to three-stage fine grinding by a hammer mill to less than 0.6mm, and finally two-stage high-voltage electrostatic separatio...

Embodiment 3

[0076] Centrifugal rotating heating equipment is used to remove the components on the discarded circuit boards and recover them into solder, components and substrates respectively. The solder is packaged and sold directly, and the components are tested according to relevant standards and sold separately. If the components fail to meet the standards, they may be broken together with the substrate. The substrate is firstly crushed by impact shearing, and the crushing particle size is below 20mm. After secondary crushing, the particle size is below 3mm. At this time, the magnetic material (Fe) and the non-magnetic material are separated by a magnetic separator to obtain iron materials. And non-ferrous materials, for non-ferrous materials, remove aluminum by eddy current separation, then carry out three-stage fine grinding to less than 0.6mm by hammer mill, and finally obtain metal materials containing about 82.9% copper by two-stage high-voltage electrostatic separation , and non...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com