Local large-size fiber letterpress printing system and printed matter thereof

A large-size, fiber technology, applied in the field of local large-size fiber embossing (machine) system and its printed matter, can solve the problems of long order cycle, inability to use ink, and high cost, and achieve high-speed, low-cost production, easy processing, Flexibility-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

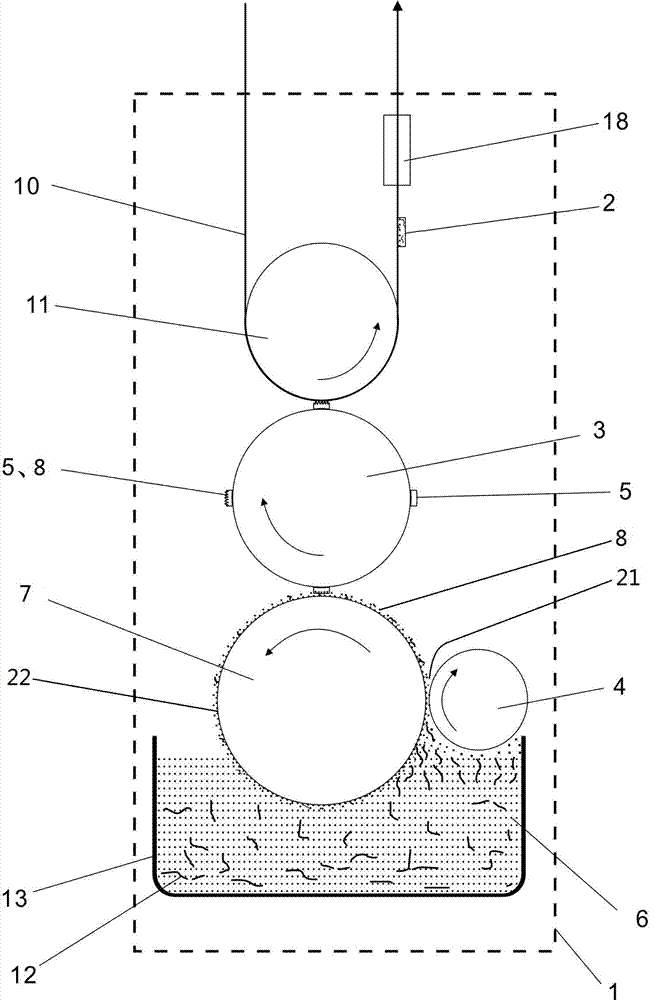

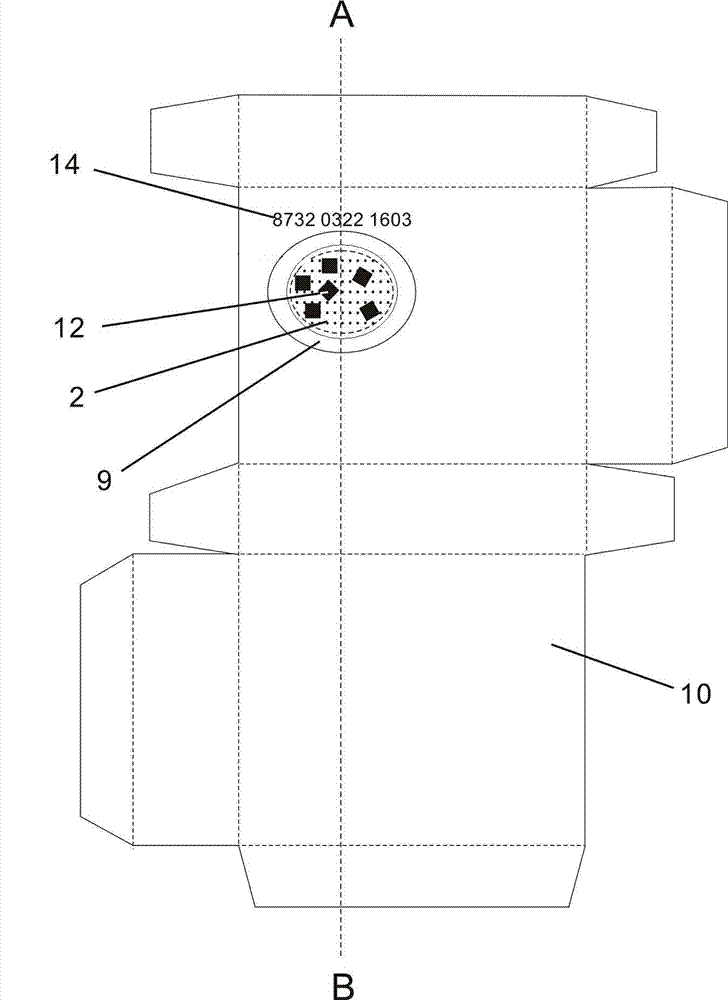

[0050] Such as figure 1 , Figure 4 As shown, a local large-scale fiber embossing (machine) system is designed and manufactured.

[0051] According to the technical standard of the current embossing machine, make a material discharging unit (19) and a material receiving The unit (20) is used to send the continuous printing material (10) from the discharging unit (19) to the receiving unit (20) for collection.

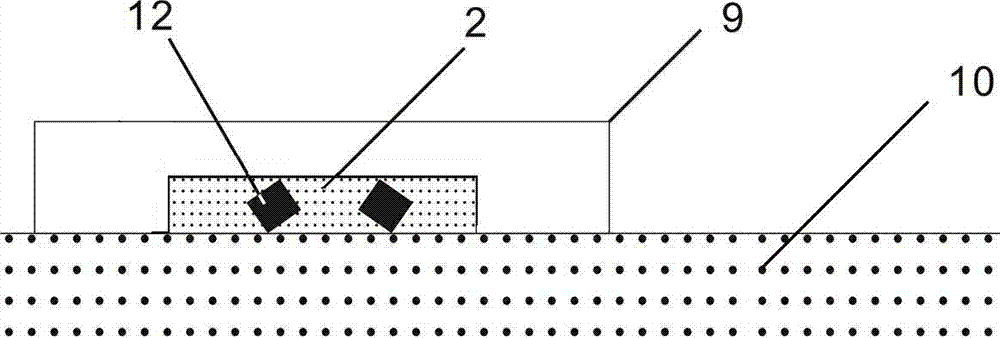

[0052] Then install the fiber ink embossing unit (1), which is arranged between the discharging unit (19) and the receiving unit (20), for printing partial fiber ink blocks on the printing material (10) (2).

[0053] Prepare 9.269kg of transparent UV ink, add 0.731kg of golden square glitter powder with a width of 0.8mm and a thickness of 16μm into the ink, stir well to form a fiber ink (6) with a viscosity of 4000-12000 centipoise, and then pour it into In the ink tank (13).

[0054] The fiber ink embossing unit (1) includes a parallel and tangential embossed pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com