Cylinder for a printing unit of a printing machine and method for swapping out the printing sleeve of such a cylinder

A technology for printing sleeves and printing presses, which is applied to general parts of printing machinery, printing presses, rotary printing presses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

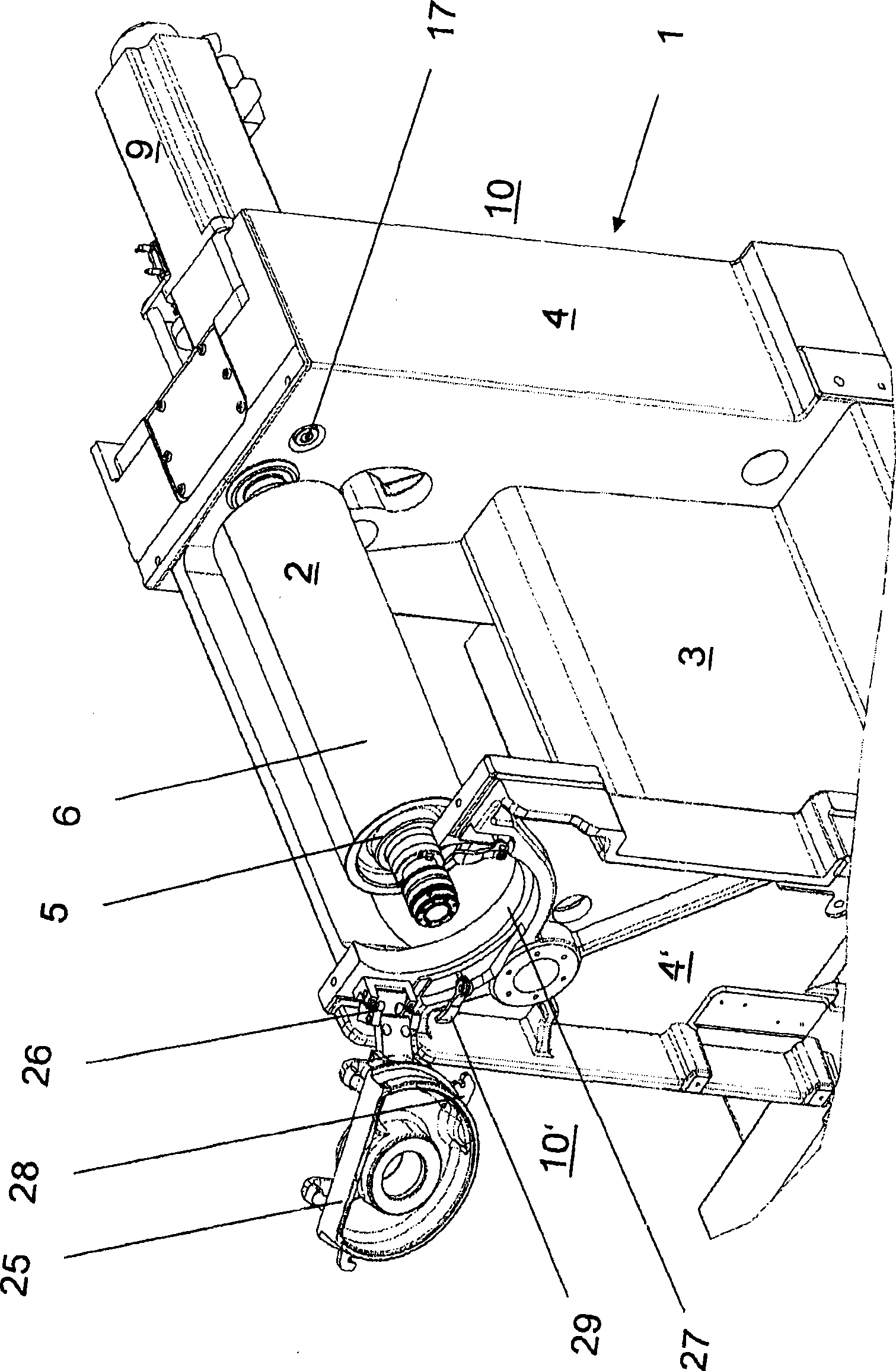

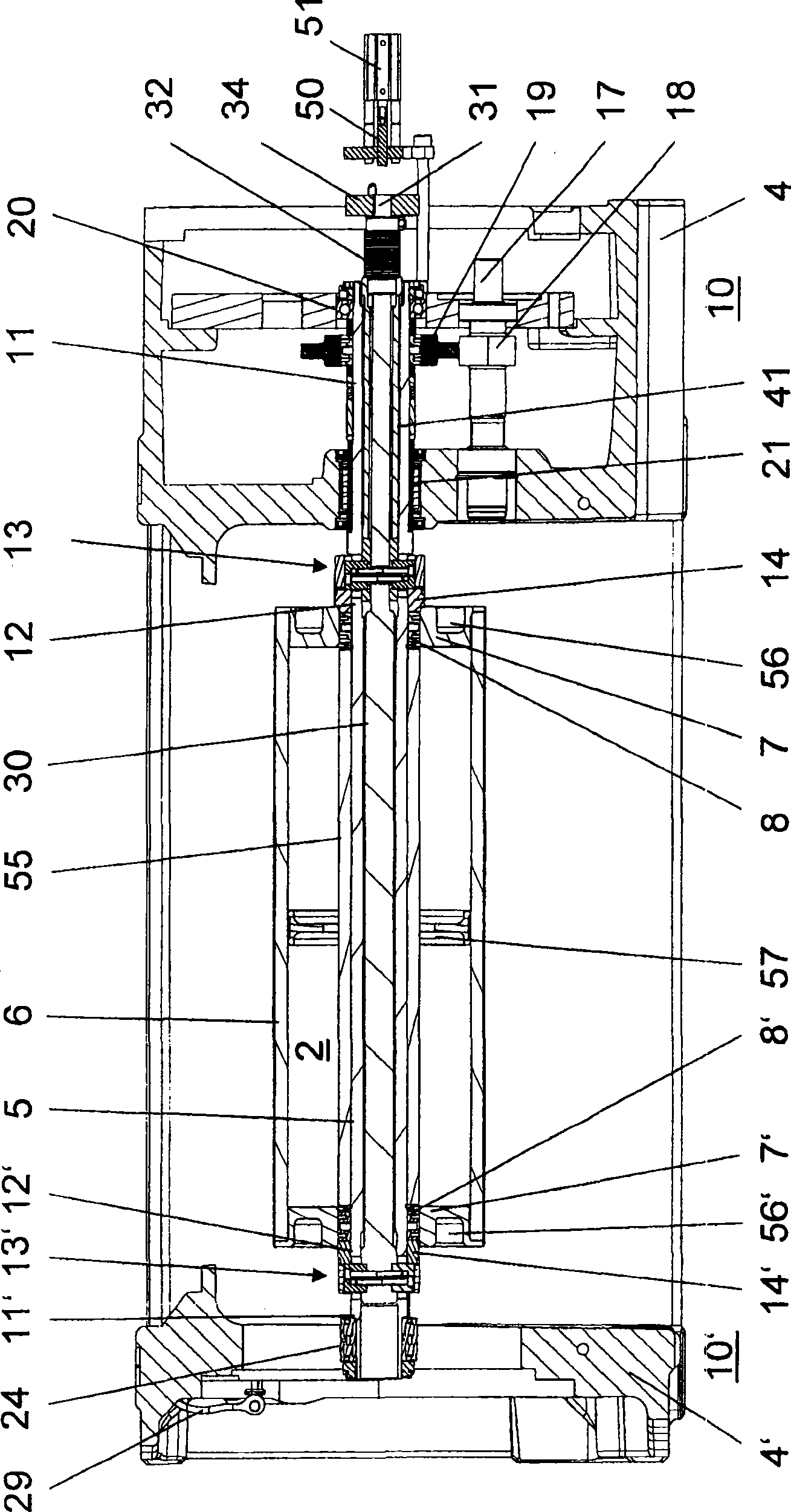

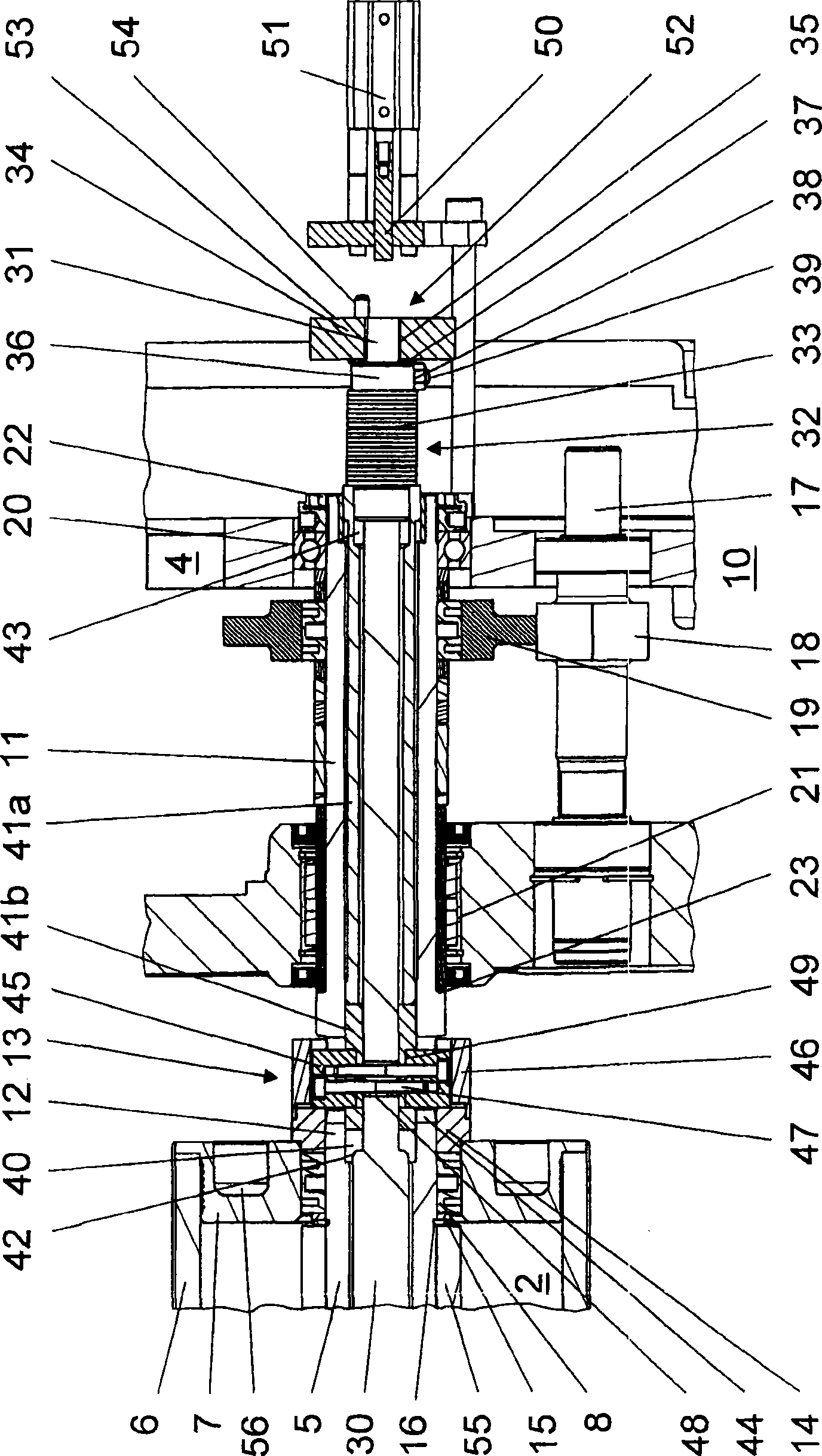

[0029] figure 1 A side view of the printing unit 1 of an offset printing press is shown, limited to the parts necessary for understanding the invention. Furthermore, the printing unit 1 is provided with a cylinder 2 , of which a blanket cylinder is shown, for example, here. The printing unit 1 has a housing 3 with two side panels 4 , 4 ′ for supporting the cylinder 2 . The other parts that also belong to the printing unit 1 , such as the plate and impression cylinders as well as the coloring and dampening units, are not shown for reasons of better simplicity.

[0030] The cylinder 2 consists of a cylinder core designed as a bearing shaft 5 to which a printing plate part designed as a printing sleeve 6 is detachably connected. The printing sleeve 6 has at its two end faces a respectively inserted support ring 7, 7', which in the installed state is supported by a first clamping sleeve designed as a clamping sleeve sitting on the support shaft 5. Or the second clamping part 8,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com