Method of printing curved surface and curved surface body printed by using same

A technology of curved surface printing and curved body, applied in printing, printing presses, rotary printing presses, etc., can solve the problems of large ink volume, consuming a lot of time and energy, low printing accuracy, etc., and achieve the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

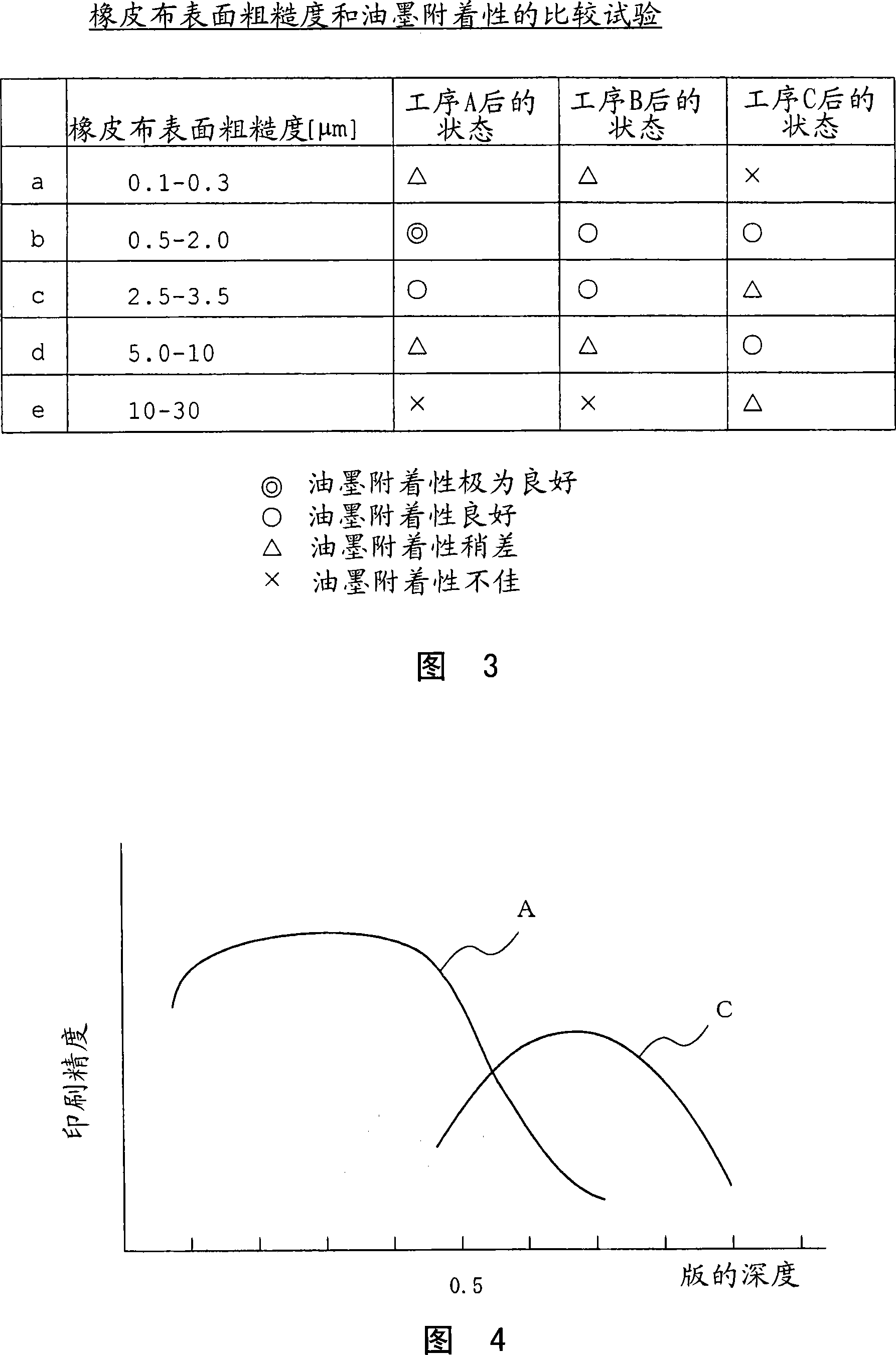

[0089] Samples printed on curved surfaces:

[0090] D×L30mmφ×100mm polypropylene cylinder

[0091] Peripheral 180° surface printing

[0092] Blankets for curved surface printing:

[0093] R1, 2×L1 (bottom width)×top r 90mm×105mm×15mm

[0094] Material Silicone Rubber Hardness (JIS Class A) 15

[0095] Surface roughness a(0.1~0.3μm), b(0.5~2μm),

[0096] c(2.5~3.5μm), d(5~10μm), e(10~30μm)

[0097] Use ink:

[0098] UV ink

[0099] Letterpress Original:

[0100] Aluminum relief plate Sensitizer convex height 1μm

[0101] Standard grid pattern with line width 0.5±0.02mm and grid interval 5±0.3mm

[0102] printing press:

[0103] Horizontal moving 3-stage blanket printing machine (SHUHO-3 type)

[0104] Fabricate curved surface printing blankets 2 with different surface roughness, perform blanket printing on the sample to be printed on the curved surface in the above-mentioned steps A to C, respectively, in the A step for the remaining ink on the original pla...

Embodiment 2

[0110] Samples printed on curved surfaces:

[0111] D×L 30mmφ×100mm polypropylene cylinder

[0112] Peripheral 180° surface printing

[0113] Blankets for curved surface printing:

[0114] R1, 2×L1 (bottom width)×top r 90mm×105mm×15mm

[0115] Material Silicone rubber

[0116] Hardness (JIS Class A) 5, 15, 30, 40, 50, 60

[0117] Surface roughness 0.5~2μm

[0118] Ink used: UV ink

[0119] Letterpress Original:

[0120] Aluminum relief plate Sensitizer convex height 1μm

[0121] Standard grid printing machine with a line width of 0.5±0.02mm and a grid interval of 5±0.3mm:

[0122] Horizontal moving 3-stage blanket printing machine (SHUHO-3 type)

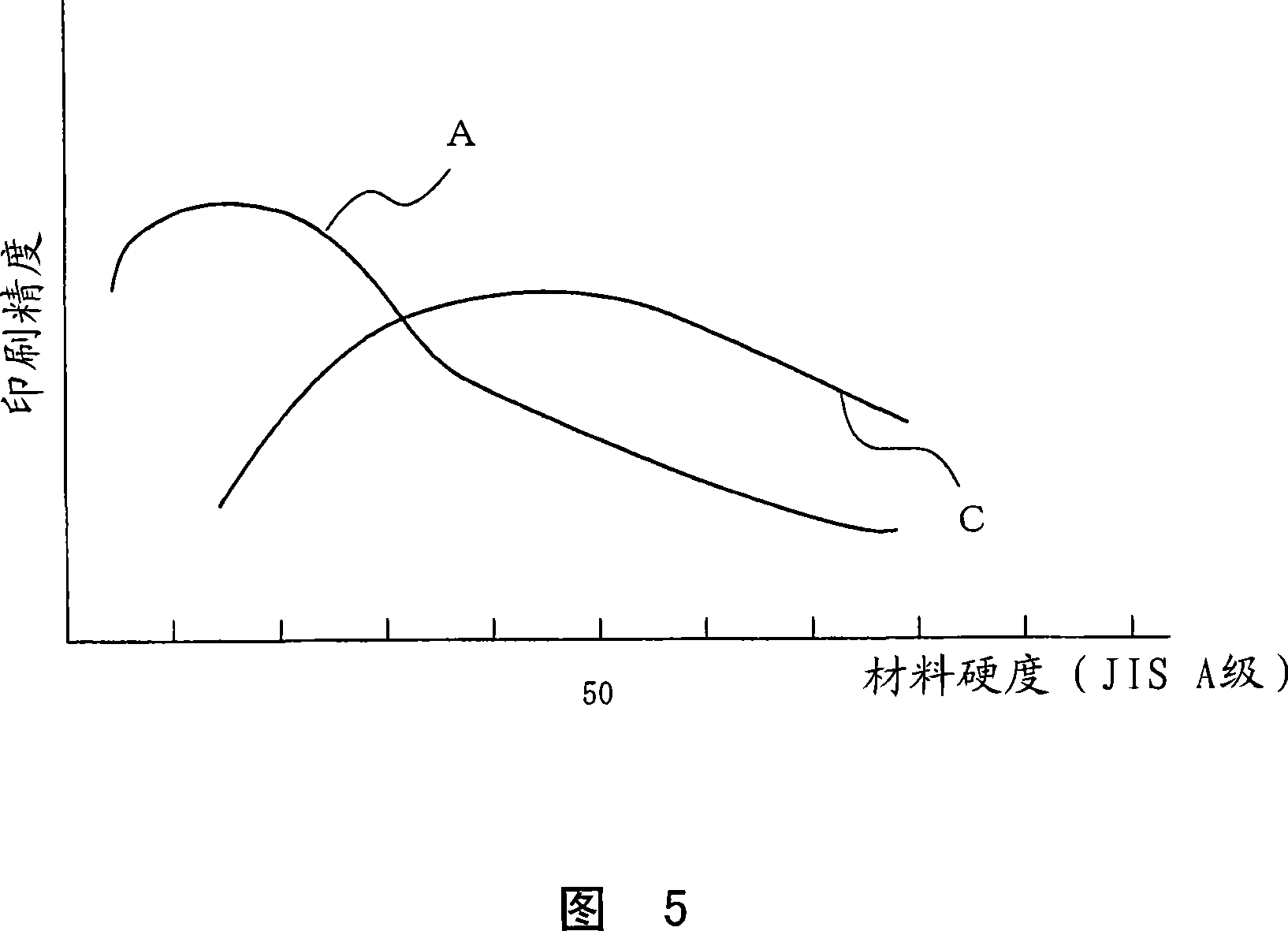

[0123] Only the hardness of the silicone rubber was changed, and other conditions remained unchanged, and the printing accuracy was compared.

[0124] FIG. 5 shows the results of experiments conducted on the relationship between the hardness H of the blanket and the printing accuracy.

[0125] Usually, silicone rubber has ...

Embodiment 3

[0128] Samples printed on curved surfaces:

[0129] D×d 400mmφ×30mmφ polypropylene ring

[0130] Printing on the surface of the ring divided into two parts in the axial direction (d outer peripheral 180° surface) × 2 times (both sides)

[0131] Blankets for curved surface printing:

[0132] R1, 2×L1×top r×D 90mm×105mm×15mm×400mm

[0133] Material silicone rubber

[0134] Hardness (JIS Class A) 15

[0135] Surface roughness 0.5~2μm

[0136] Ink used: UV type ink (color: brown, dark brown)

[0137] Letterpress Original:

[0138] Aluminum letterpress master plate Sensitizer convex height 0.2μm

[0139] Two-color fluorescent dye printing waveform non-continuous pattern

[0140] The upper and lower sides of the ring were physically printed twice, and as a result of the second printing, it was found that there were some printing misalignments on the printing joint surface, especially on the inner diameter side of the ring, but it was still within the allowable range as a com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com