Graphene/nano-silver light-sensitive conductive composite paste and preparation method therefor

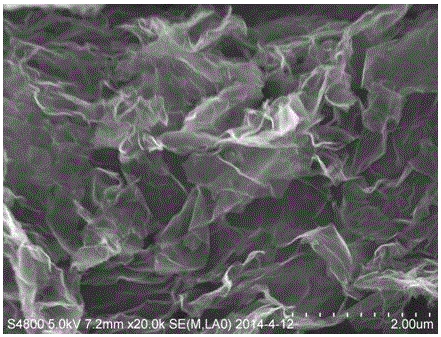

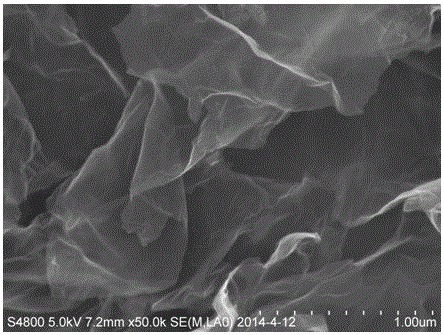

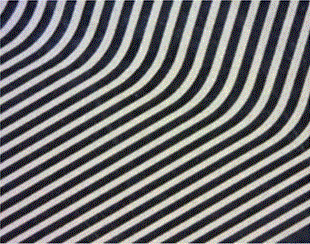

A technology of composite slurry and graphene, which is applied in cable/conductor manufacturing, conductive materials dispersed in non-conductive inorganic materials, nanotechnology, etc., can solve the problems of low conductivity, insufficient strength and complicated process, etc., and achieve development Clean and clear, clear graphics, good particle size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]In parts by weight, photosensitive resin 20, novolak epoxy resin (F-51) 5, graphene 15, spherical nano-silver powder (NAg-20D) 50, photoinitiator (907) 3, dispersant (polyurethane AFCONA- 4010) 4. Defoamer (organic silicon AFCONA-2501) 2. Propylene glycol methyl ether acetate 50, divalent ester 80

[0038] 1) Take 15 parts by mass of graphene and dry it in a vacuum drying oven (baking at 100°C for 4h) to remove moisture;

[0039] 2) Under the condition of yellow light, mix photosensitive resin 20, thermosetting resin (F-51) 5, graphene 15, nano-silver powder 50, dibasic acid ester 80, dispersant (AFCONA-4010) 4 Mix and add to a mixer, control the rotation speed at 1000 rpm, and stir for 2 hours to obtain the first mixture;

[0040] 3) Add the first mixture to a nano sand mill for graded grinding and dispersion under yellow light conditions; specifically, grind and disperse for 4 hours under the condition of zirconium beads with a particle size of 1.0 mm; then grind and ...

Embodiment 2

[0043] In parts by weight, photosensitive resin 40, novolac epoxy resin (F-51) 8, graphene 20, nano silver powder (NAg-20D) 50, photoinitiator (TPO) 3, dispersant (polyurethane AFCONA-4010 ) 4. Defoamer (organic silicon AFCONA-2501) 2. Propylene glycol methyl ether acetate 50, divalent ester 100

[0044] 1) Take 20 parts by mass of graphene and dry it in a vacuum drying oven (baking at 100°C for 4 hours) to remove moisture;

[0045] 2) Under the condition of yellow light, mix photosensitive resin 40, thermosetting resin (F-51) 8, graphene 20, nano-silver powder 60, divalent ester 1000, dispersant (AFCONA-4010) 4 according to the above mass parts Mixed and added to the mixer, the control speed is 1000rpm, and the stirring time is 2h;

[0046] 3) Add the first mixture to the nano sand mill under yellow light conditions for graded grinding and dispersion (zirconium beads with a particle size of 1.0 mm are ground and dispersed for 4 hours, and zirconium beads with a particle size...

Embodiment 3

[0049] In parts by weight, photosensitive resin 30, novolac epoxy resin (F-51) 10, graphene 20, nano silver powder (NAg-20D) 50, photoinitiator (907) 3, dispersant (polyurethane AFCONA-4010 ) 4. Defoamer (organic silicon AFCONA-2501) 2. Propylene glycol methyl ether acetate 50, divalent ester 100

[0050] 1) Take 20 parts by mass of graphene and dry it in a vacuum drying oven (baking at 100°C for 4 hours) to remove moisture;

[0051] 2) Under the condition of yellow light, according to the above mass parts, mix photosensitive resin 30, thermosetting resin (F-51) 5, graphene 20, nano-silver powder 60, divalent ester 80, dispersant (AFCONA-4010) 4 Mix and add to a mixer, control the rotation speed at 1000 rpm, and stir for 2 hours to obtain the first mixture;

[0052] 3) Add the first mixture to the nano sand mill under yellow light conditions for graded grinding and dispersion (zirconium beads with a particle size of 1.0 mm are ground and dispersed for 4 hours, and zirconium b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com