Method for producing corrugated box sheet

A production method and technology for corrugated box sheets, which are applied in chemical instruments and methods, layered products, paper/cardboard layered products, etc., can solve problems such as unfavorable industrialized continuous production, low strength and low efficiency of corrugated fragile box sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with accompanying drawing by embodiment:

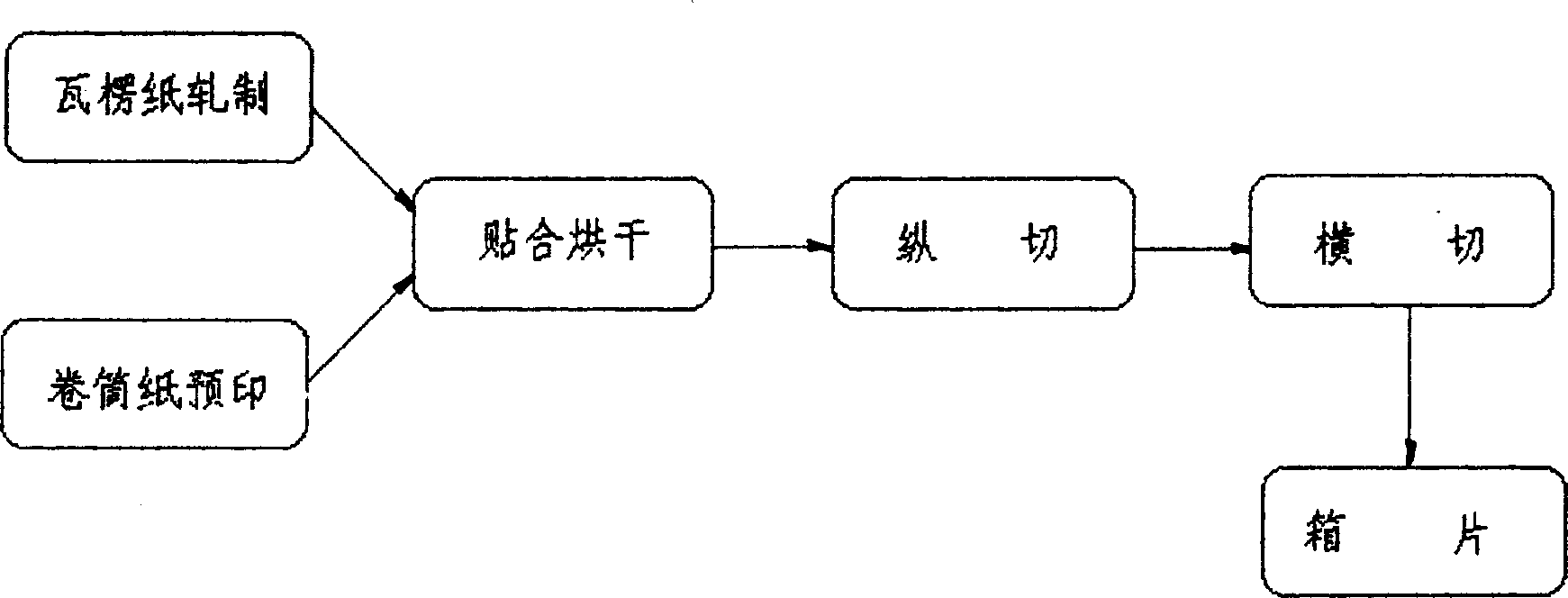

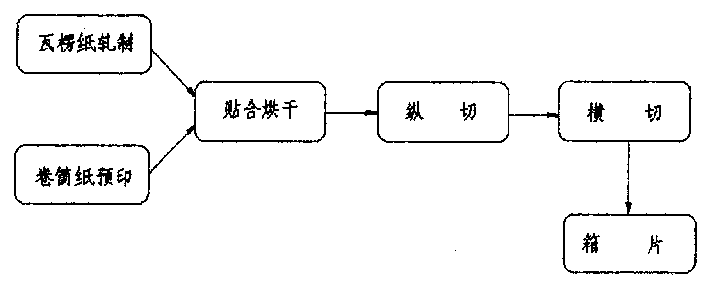

[0009] The process steps of the production method include: web (120g / square meter-300g / square meter) pre-printing, corrugated paper rolling, bonding and drying, longitudinal cutting, cross cutting and box sheeting. The steps of web pre-printing consist of web unwinding, multi-color gravure (flexo) printing, and post-press winding. Then, the pre-printed web is fed into the corrugated board production line and laminated with the rolled corrugated paper. Dried, then longitudinally cut and crosscut into box pieces. The corrugated board production line includes four processes of corrugated paper rolling, lamination and drying, slitting, and cross-cutting. Five-layer and three-layer corrugated board production lines can be selected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com