Preparation method of electroluminescent anti-counterfeiting trademark structure

An electroluminescent layer and electroluminescent technology, which is applied in the field of anti-counterfeiting trademarks, can solve the problem of actual anti-counterfeiting ability, and achieve the effects of improving anti-counterfeiting performance, convenient use and strong anti-counterfeiting performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

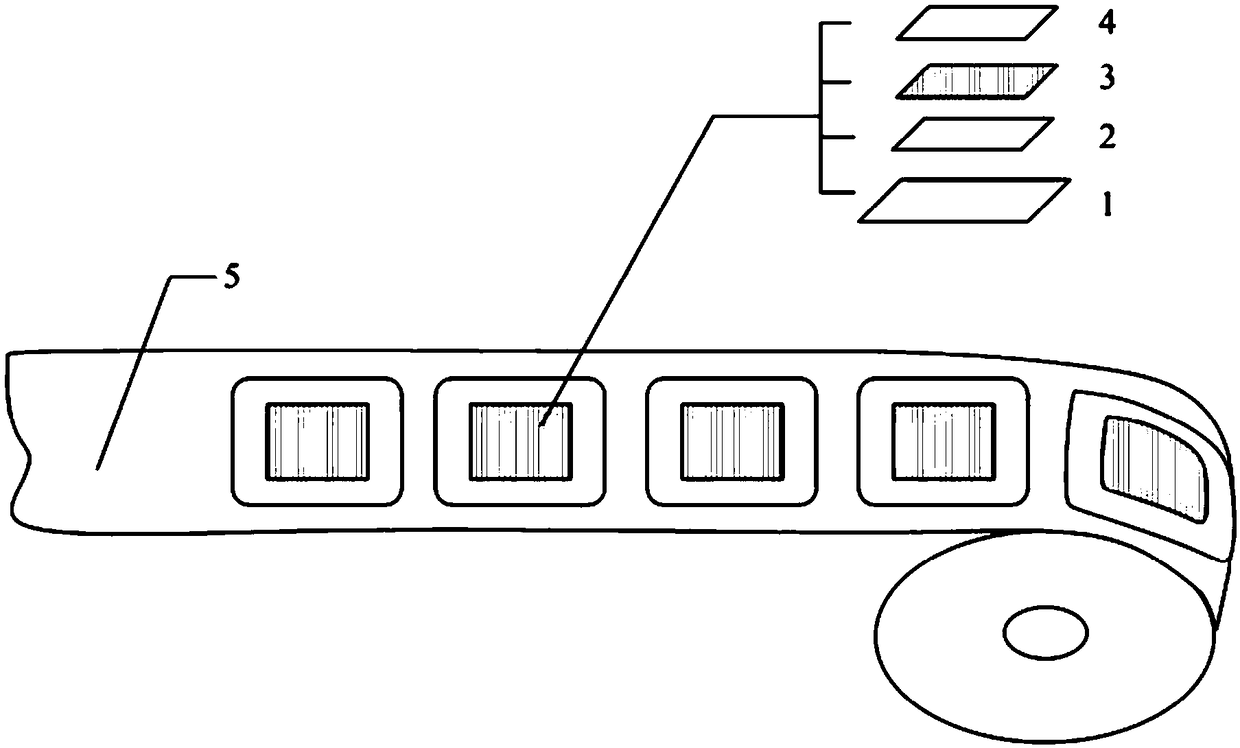

[0032] Manganese-doped zinc sulfide nanoparticles are ultrasonically stirred and dispersed in a mixed solvent of water, ethylene glycol and polymer to make a slurry ink for printing the electroluminescent layer for screen printing;

[0033] On the release paper, the conductive ink layer, electroluminescent layer, and conductive ink layer are printed layer by layer on the anti-counterfeiting mark pattern area by using screen printing technology to form an electroluminescent anti-counterfeiting trademark;

[0034] The anti-counterfeiting trademark is detected by a detector using a commercial button battery as the power source, and the trademark is stimulated to emit light through physical contact as the basis for anti-counterfeiting.

Embodiment 2

[0036] Cobalt-doped zinc selenide nanoparticles are ultrasonically dispersed in a mixed solvent of water, ethylene glycol and polymer to make a slurry ink for printing the electroluminescent layer for gravure printing;

[0037] On the release paper, the conductive ink layer, electroluminescent layer, and conductive ink layer are printed layer by layer on the anti-counterfeiting mark pattern area by gravure printing technology to form an electroluminescent anti-counterfeiting trademark;

[0038] The anti-counterfeiting trademark is detected by a detector using a commercial button battery as the power source, and the trademark is stimulated to emit light through physical contact as the basis for anti-counterfeiting.

Embodiment 3

[0040] Disperse iron-doped zinc sulfide nanoparticles in a mixed solvent of water, ethylene glycol and polymer by mechanical stirring to make a paste ink for printing the electroluminescent layer for letterpress printing;

[0041] On the release paper, the conductive ink layer, electroluminescent layer, and conductive ink layer are printed layer by layer on the anti-counterfeiting mark pattern area by letterpress printing technology to form an electroluminescent anti-counterfeiting trademark;

[0042] The anti-counterfeiting trademark is detected by a detector using a commercial button battery as the power source, and the trademark is stimulated to emit light through physical contact as the basis for anti-counterfeiting.

[0043] Compared with traditional fluorescent inks, electroluminescence has excellent anti-counterfeiting trademark characteristics, and the ink formula is difficult to copy, which greatly improves the anti-counterfeiting performance of printed matter. Based ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com