Letterpress printing and large-piece product quality inspection combination machine

A product quality and combined machine technology, which is applied to printing presses, rotary printing presses, general parts of printing machinery, etc., can solve the problems of consuming a lot of manpower and material resources, combining the two into one without final quality inspection, and leaving the warehouse of finished products. To achieve the effect of simplifying the production process, shortening the product circulation process and reducing restraint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

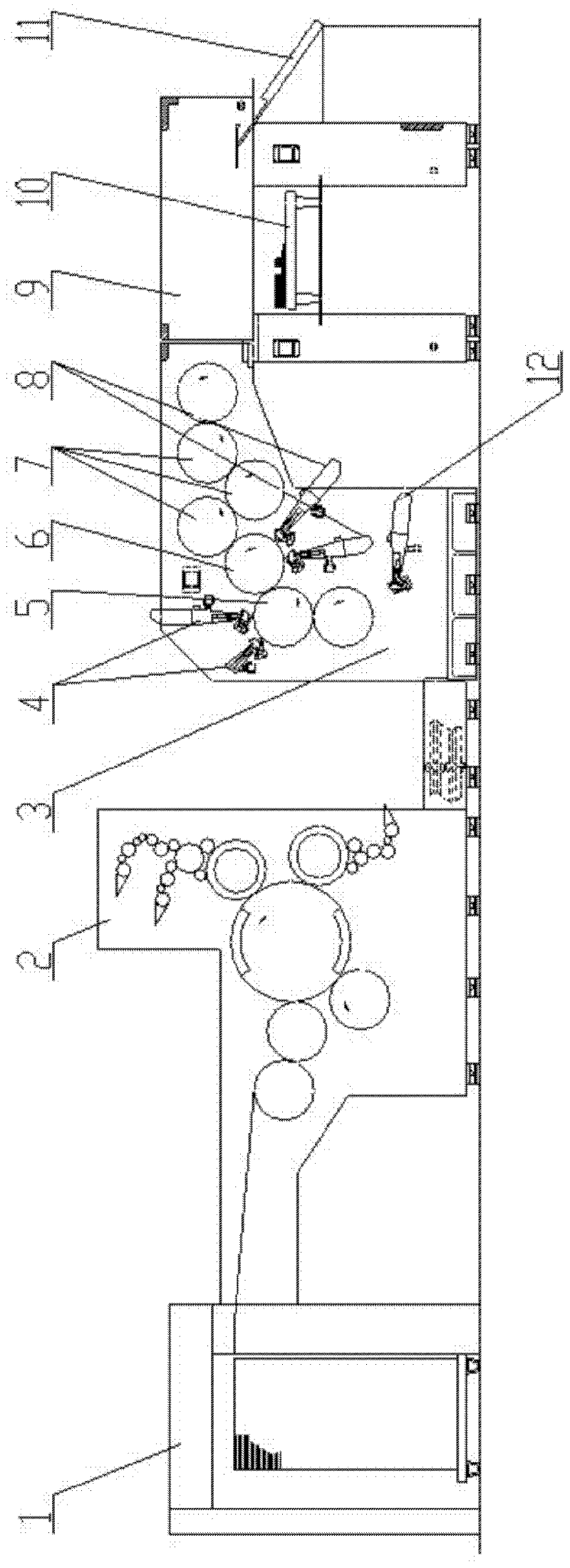

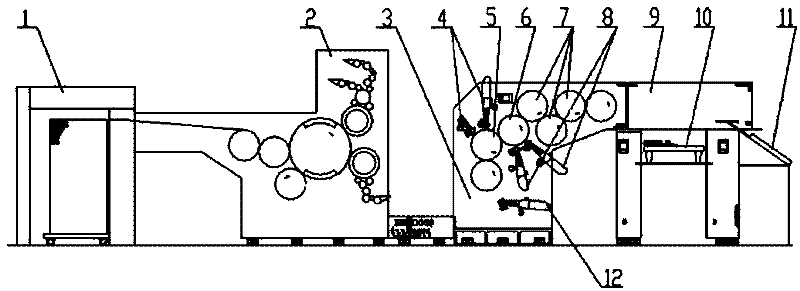

[0018] The present invention print code and large product quality inspection combined machine such as figure 1 As shown, the paper feeding part 1 and the code printing part 2 adopt the original parts of the original multi-functional code printing machine. After the code is printed, the product is transmitted to the perspective inspection department by the paper transmission chain drive 3, and the high-precision CCD camera and high stability The perspective inspection device 12 composed of a permanent light source checks the quality of the watermark; then, the product is passed to the front detection cylinder 5, and the front detection device 4 composed of a high-precision color CCD camera and a high-stability light source checks the front fluorescence of the product and the graphic printing of the full face of the product. The quality is checked; then, the product is passed to the back detection roller 6, and the back detection device 8 composed of a high-precision color CCD ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com