Fin heat exchange pipe and and its manufacturing method

A manufacturing method and technology of heat exchange tubes, applied in the direction of tubular elements, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of poor heat resistance and corrosion resistance of galvanized fin heat exchange tubes, and reduce production costs , Alleviate the contradiction between supply and demand, excellent atmospheric corrosion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

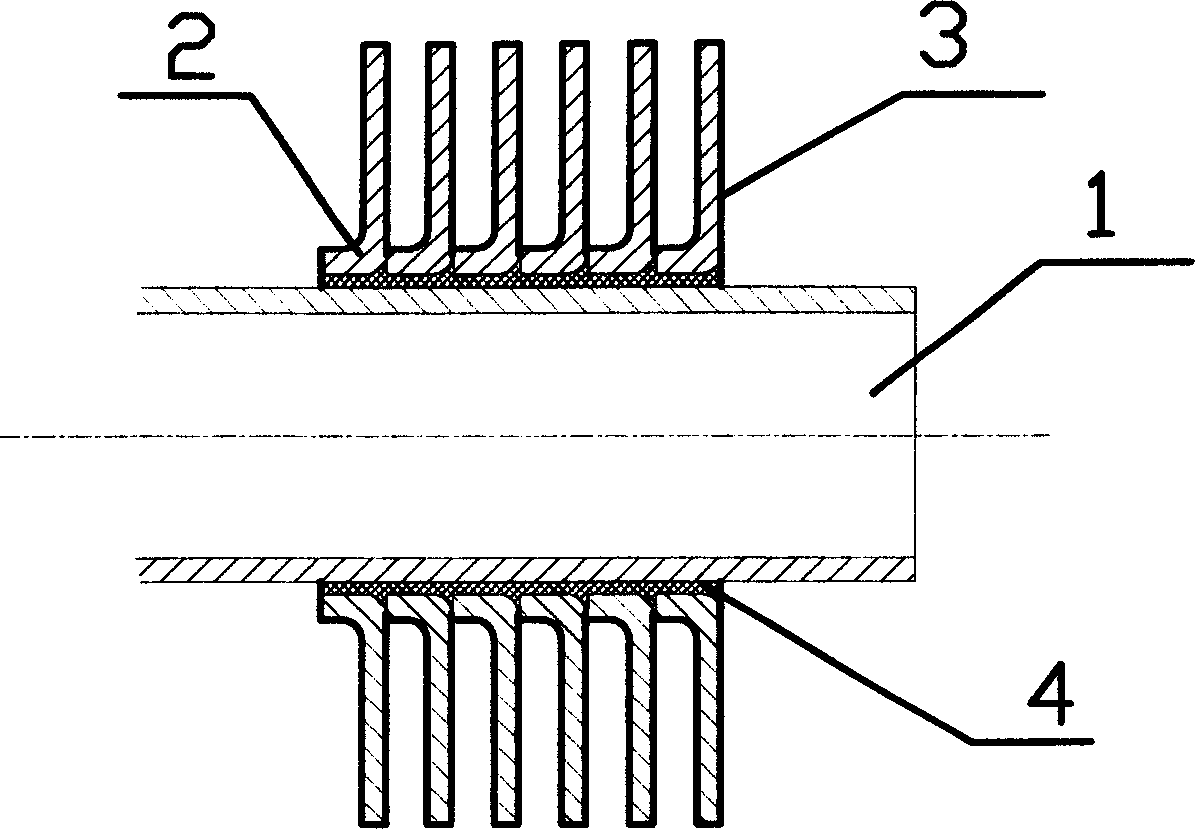

[0016] See figure 1 , The finned heat exchange tube of the present invention and its manufacturing method are composed of a base tube 1, a fin or a fin 2. After the base tube 1 and the fins or fins 2 are assembled, the welding metal layer 4 and the fin surface plating layer 3 between the fins or the fins and the base tube are formed by hot-dip aluminum or aluminum alloy. The specific process steps of the method are as follows:

[0017] a. Assemble the fin fins and the base tube. There are two types of fin tube assembly: (1) After punching the fins one by one, install the fins on the heat exchange base tube mechanically or manually (2) Pass the long fins mechanically Wrap around the base tube. The base tube can be oval, approximately oval or circular. The fins at both ends of the assembled fin tube need to be fixed to prevent the position of the fins from changing during subsequent processes and transportation.

[0018] b. Pre-treat the finned tube. That is, degreasing and rust rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com