Wallboard binder and preparation method thereof

An adhesive and wallboard technology, applied in the field of building materials, can solve the problems of high adhesive cost, short setting time, poor adhesion, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

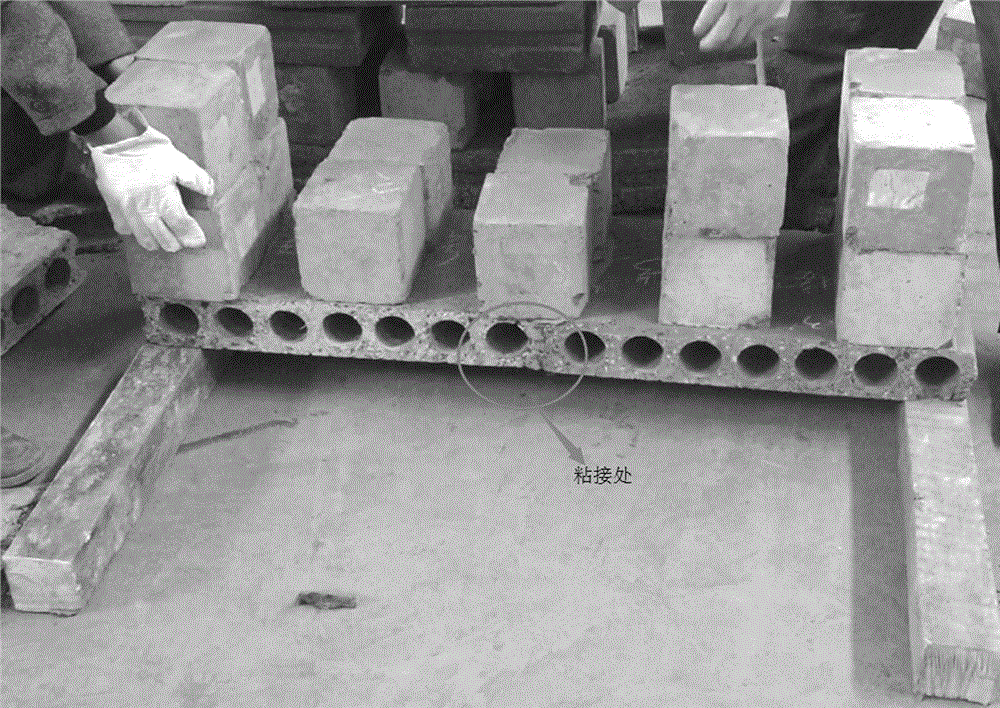

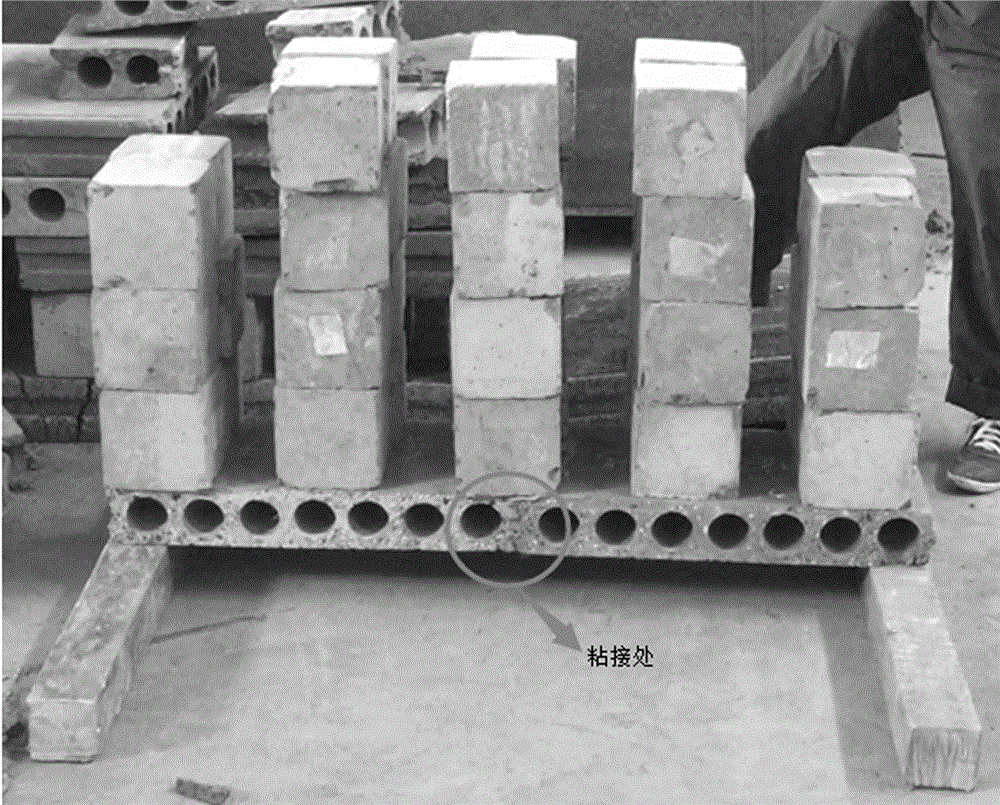

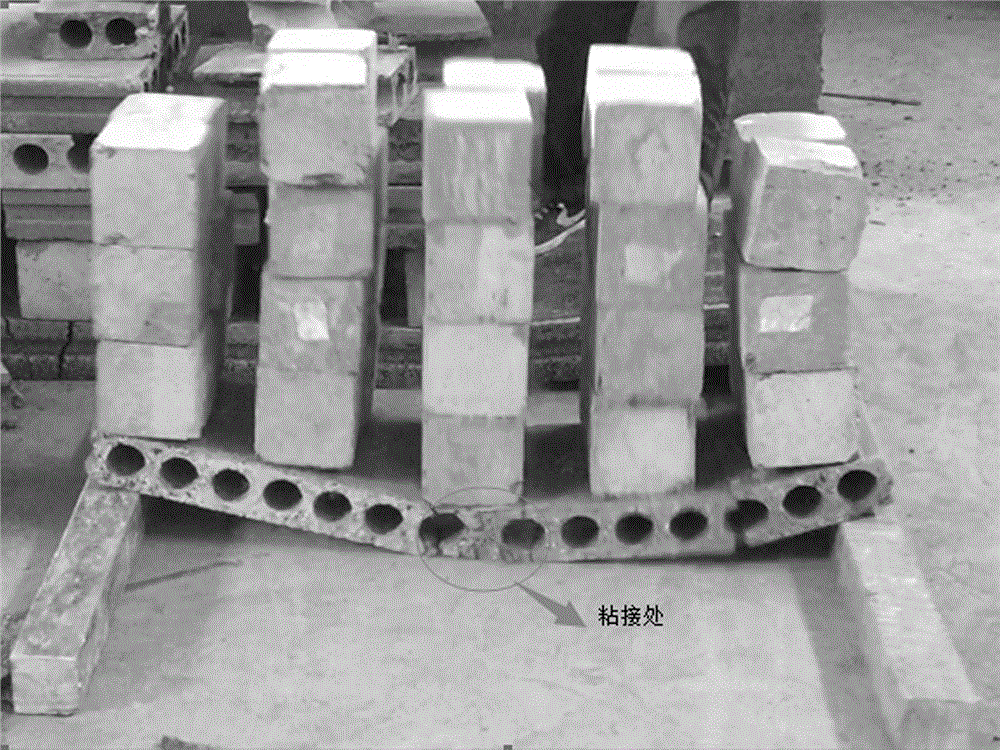

Image

Examples

Embodiment 1

[0021] Embodiment 1: a kind of preparation method of wallboard adhesive, formula of the present invention:

[0022] Ordinary Portland cement: 8kg

[0023] Methylcellulose (HPMC), viscosity 85000: 8g

[0024] Water: 5kg;

[0025] Preparation: first put 5kg of water into the mixing bucket, then take out 8g of methyl cellulose (HPMC) and pour it into the mixing bucket, stir with a stirrer with a rotation speed of 10~12r / s for 150~180s, until the liquid is When it becomes thick, finally add 8kg of ordinary Portland cement and continue stirring for 150~180s.

Embodiment 2

[0026] The difference between embodiment 2 and embodiment 1 is only: the formula of the present invention is:

[0027] Ordinary Portland cement: 8kg

[0028] Methylcellulose (HPMC), viscosity 85000: 0.8g

[0029] Water: 4.88kg;

Embodiment 3

[0030] The difference between embodiment 3 and embodiment 1 is only: the formula of the present invention is:

[0031] Ordinary Portland cement: 8kg

[0032] Methylcellulose (HPMC), viscosity 85000: 24g

[0033] Water: 5.12kg;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com