420 MPa weatherproof bridge steel with high ductility and method for manufacturing hot rolled coil of 420 MPa weatherproof bridge steel with high ductility

A hot-rolled coil and high-toughness technology is applied in the field of high-toughness weathering steel for bridges and the preparation of coils. Excellent corrosion resistance

Inactive Publication Date: 2011-04-20

MAANSHAN IRON & STEEL CO LTD

View PDF11 Cites 36 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Chinese patents 85108118, 00133579.0, and 00121262.1 are all low-alloy structural steels with certain atmospheric corrosion resistance, which are Cu-P-Cr-Ni or Cu-P-Ti-RE weathering steels, with a yield strength of 350MPa and low temperature impact low performance

Chinese patent 200410061112.4 discloses a high-strength weathering steel with needle-like structure and its production method. Its components are low carbon, Cu-Cr-Ni-Mo-Nb-Ti-Al-Zr-RE or Ca. Although the strength and low-temperature toughness are good, it is expensive to add Mo, RE, and Zr at the same time, and it is difficult to smelt

Chinese patent 200510111858.6 discloses a high-strength low-alloy atmospheric corrosion-resistant steel whose composition is carbon 0.05-0.1%; silicon: ≤0.75%; manganese: 1.0-1.6%; phosphorus: ≤0.02%; sulfur: ≤0.01%; Aluminum: 0.01-0.05%; Nickel: 0.12-0.40%; Chromium: 0.20-0.45%; Copper: 0.20-0.55%; Calcium: 0.001-0.006%; Nitrogen: 0.001-0.006%; 0.025%; molybdenum ≤ 0.35%, the yield strength of this steel can reach 550MPa, the cost is lower than 200410061112.4, but its low temperature impact performance is poor

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-5

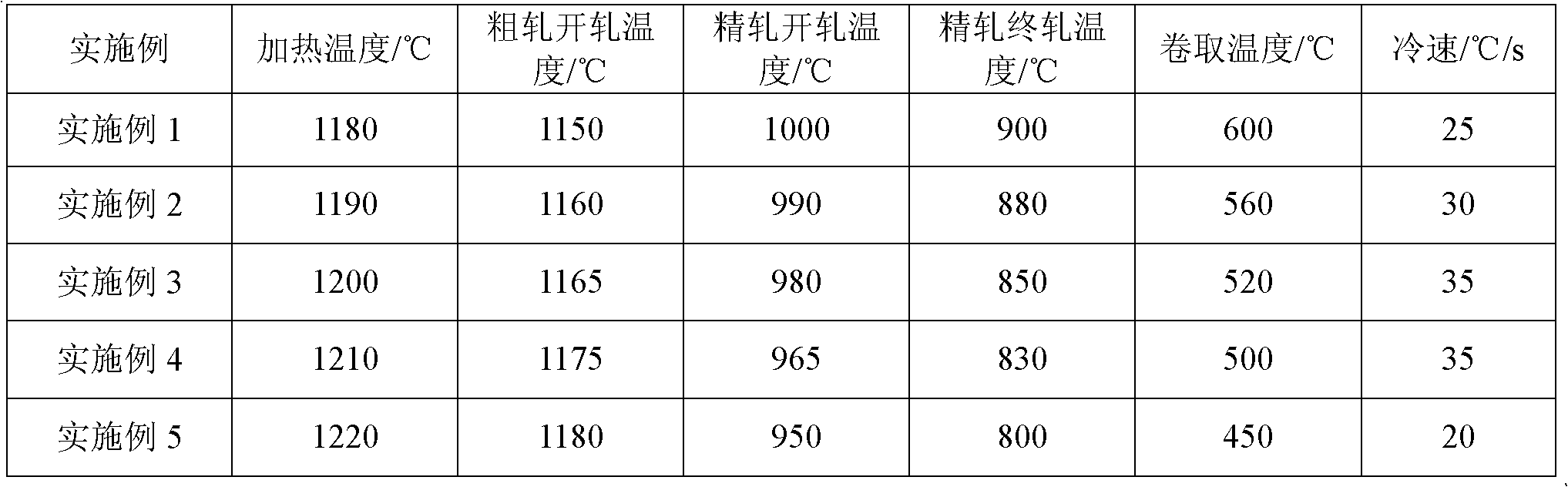

[0035] Table 2. Embodiment 1-5 TMCP process system

[0036]

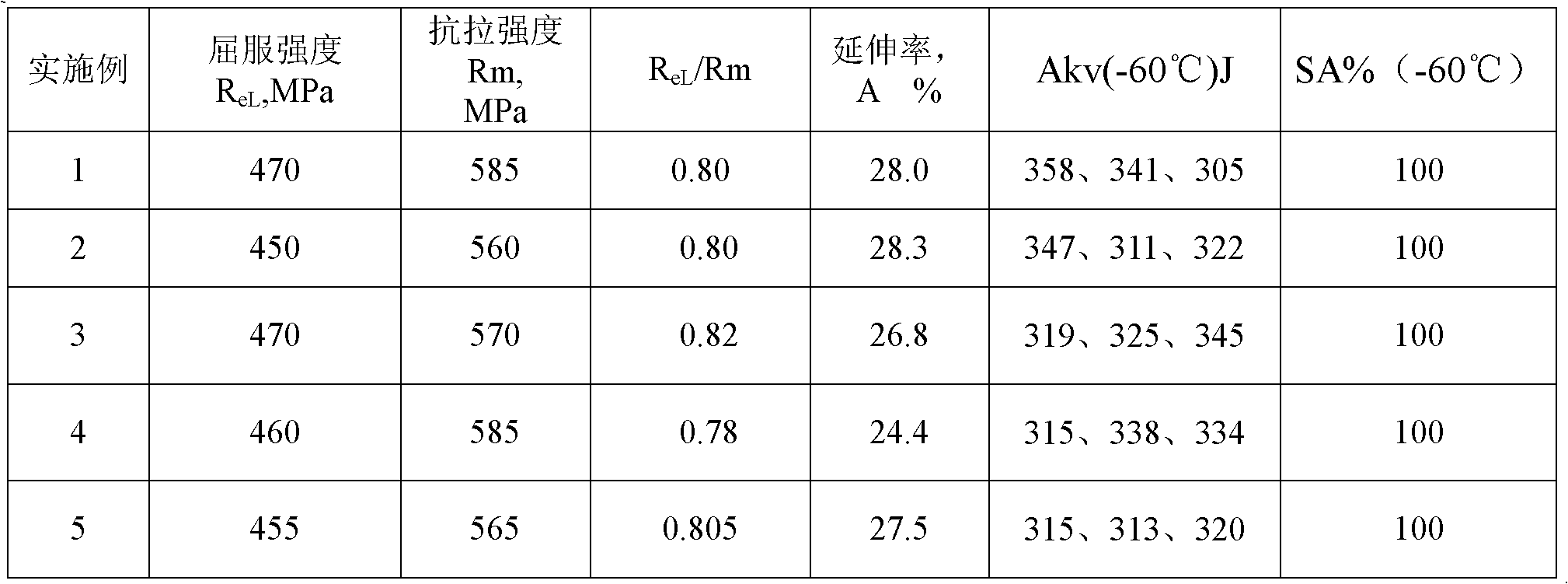

[0037] Table 3 embodiment 1-5 mechanical property inspection result

[0038]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a 420 MPa weatherproof bridge steel with high ductility, which is characterized by comprising the following chemical compositions in percentage by weight: 0.015-0.045% of carbon, 0.20-0.35% of silicon, 1.20-1.50% of manganese, less than or equal to 0.018% of phosphorus, less than 0.0005% of sulfur, 0.030-0.050% of niobium, 0.010-0.020% of titanium, 0.015-0.040% of aluminum, 0.25-0.40% of nickel, 0.25-0.50% of chromium, 0.25-0.40% of copper, 0.0002-0.003% of B, less than or equal to 0.006% of nitrogen, less than or equal to 0.002% of oxygen, and the balance of ferrum and trace impurities. The rolled coil of the 420 MPa weatherproof bridge steel with high ductility has the advantages of good intensity, ductility, weldability, corrosion resisting property, and proper production cost.

Description

technical field [0001] The invention relates to a low-alloy corrosion-resistant steel and a method for preparing the coil, in particular to a high-toughness weather-resistant steel for bridges and a method for preparing the coil. Background technique [0002] The bridge manufacturing industry continues to put forward higher requirements for the strength, toughness, weldability and corrosion resistance of bridge steel, and this development momentum will continue in the next few decades. In recent years, with the construction of the Donghai Bridge and the Hangzhou Bay Bridge, the bridge manufacturing industry has not only required the performance of bridge steel to improve the strength and toughness of the material, but also put forward clear requirements for the seawater corrosion resistance of the material. [0003] Chinese patents 85108118, 00133579.0, and 00121262.1 are all low-alloy structural steels with certain atmospheric corrosion resistance, which are Cu-P-Cr-Ni or C...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/54C22C33/04C21D8/02

Inventor 李忠义朱涛王炜王莹赵勇蒲玉梅王海波王小燕

Owner MAANSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com