Stainless steel with low cost, high strength and high corrosion resistance and preparation method thereof

A high-corrosion-resistant stainless steel technology, applied in the field of martensitic stainless steel, can solve the problems of low corrosion-resistant mechanical properties and high cost, and achieve the effects of good corrosion resistance, simple preparation method, and strong process controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

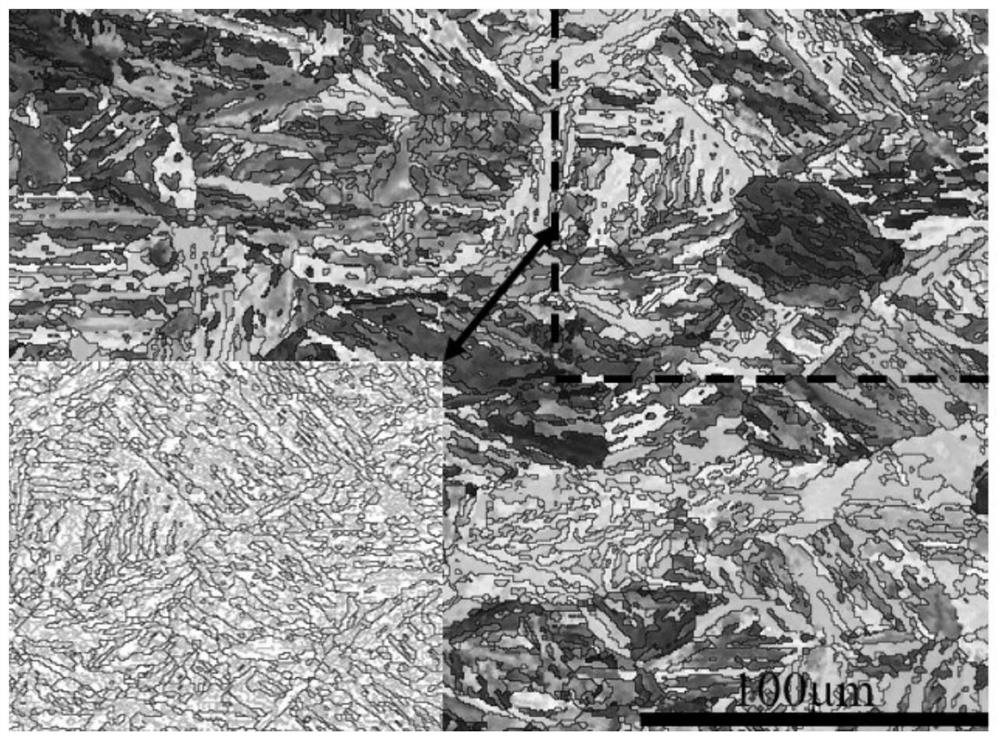

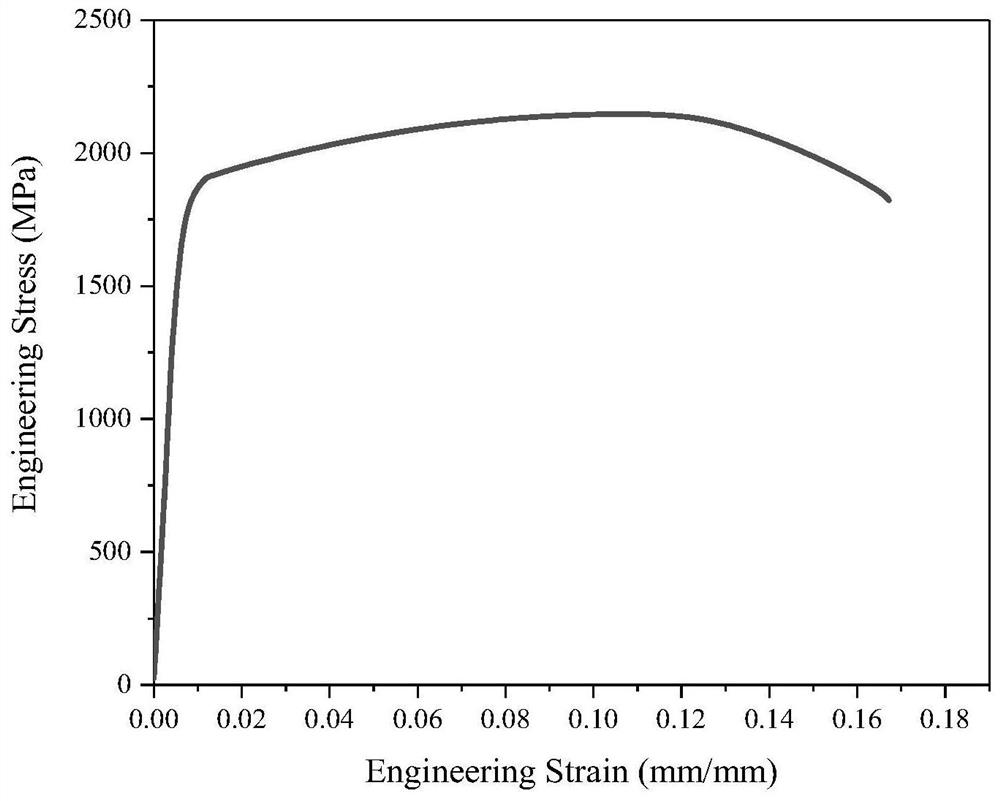

Image

Examples

Embodiment 1

[0044] Select pure iron, metal chromium, metal nickel, metal manganese, metal molybdenum, metal cobalt, metal titanium, iron silicon, iron carbon block raw materials, the composition of stainless steel is as follows (mass percentage): Co=1.0, Cr=12.0, Mn =0.1, Mo=5.0, Ni=7.0, Si=0.1, Ti=0.5, C=0.02, Fe balance.

[0045] Cast alloy ingots through arc melting or induction melting; melting is carried out in vacuum or argon protection, and stirring technology is used to mix the metal solution evenly during the melting process; protection casting is performed under vacuum or argon protection, and the size is square ingot or round ingot;

[0046] The ingot is hot-rolled by a rolling mill. The hot-rolling plan is to heat the billet to 1150±10°C, heat it for 24 hours and then roll it out of the furnace. The lower weight is 80%; the ingot can be opened by hot forging, pass rolling or universal rolling;

[0047] The plate is kept warm at 1200°C for 60 minutes, and no protective gas is...

Embodiment 2

[0050] Select pure iron, metal chromium, metal nickel, metal manganese, metal molybdenum, metal cobalt, metal titanium, iron silicon, iron carbon block raw materials, the composition of stainless steel is as follows (mass percentage): Co=4.0, Cr=12.0, Mn =0.1, Mo=5.0, Ni=7.0, Si=0.1, Ti=0.5, C=0.02, Fe balance.

[0051] Cast alloy ingots through arc melting or induction melting; melting is carried out in vacuum or argon protection, and stirring technology is used to mix the metal solution evenly during the melting process; protection casting is performed under vacuum or argon protection, and the size is square ingot or round ingot;

[0052] The ingot is hot-rolled by a rolling mill. The hot-rolling plan is to heat the billet to 1150±10°C, heat it for 24 hours and then roll it out of the furnace. The lower weight is 80%; the ingot can be opened by hot forging, pass rolling or universal rolling;

[0053] The plate is kept warm at 1050°C for 60 minutes, and no protective gas is...

Embodiment 3

[0056] Select pure iron, metal chromium, metal nickel, metal manganese, metal molybdenum, metal cobalt, metal titanium, iron silicon, iron carbon block raw materials, the composition of stainless steel is as follows (mass percentage): Co=6.0, Cr=12.0, Mn =0.1, Mo=5.0, Ni=7.0, Si=0.1, Ti=0.5, C=0.02, Fe balance.

[0057] Cast alloy ingots through arc melting or induction melting; melting is carried out in vacuum or argon protection, and stirring technology is used to mix the metal solution evenly during the melting process; protection casting is performed under vacuum or argon protection, and the size is square ingot or round ingot;

[0058] The ingot is hot-rolled by a rolling mill. The hot-rolling plan is to heat the billet to 1150±10°C, heat it for 24 hours and then roll it out of the furnace. The lower weight is 80%; the ingot can be opened by hot forging, pass rolling or universal rolling;

[0059] The plate is kept warm at 1150°C for 90 minutes, and no protective gas is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com