Anti-corrosive pre-stressed concrete pipe pile foundation

A concrete pipe pile, anti-corrosion technology, applied in infrastructure engineering, sheet pile wall, cement production and other directions, can solve the problems of anti-corrosion material falling off, affecting effect, loss of anti-corrosion function, etc., to achieve the performance of anti-sulfate Improved, better corrosion resistance, better corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

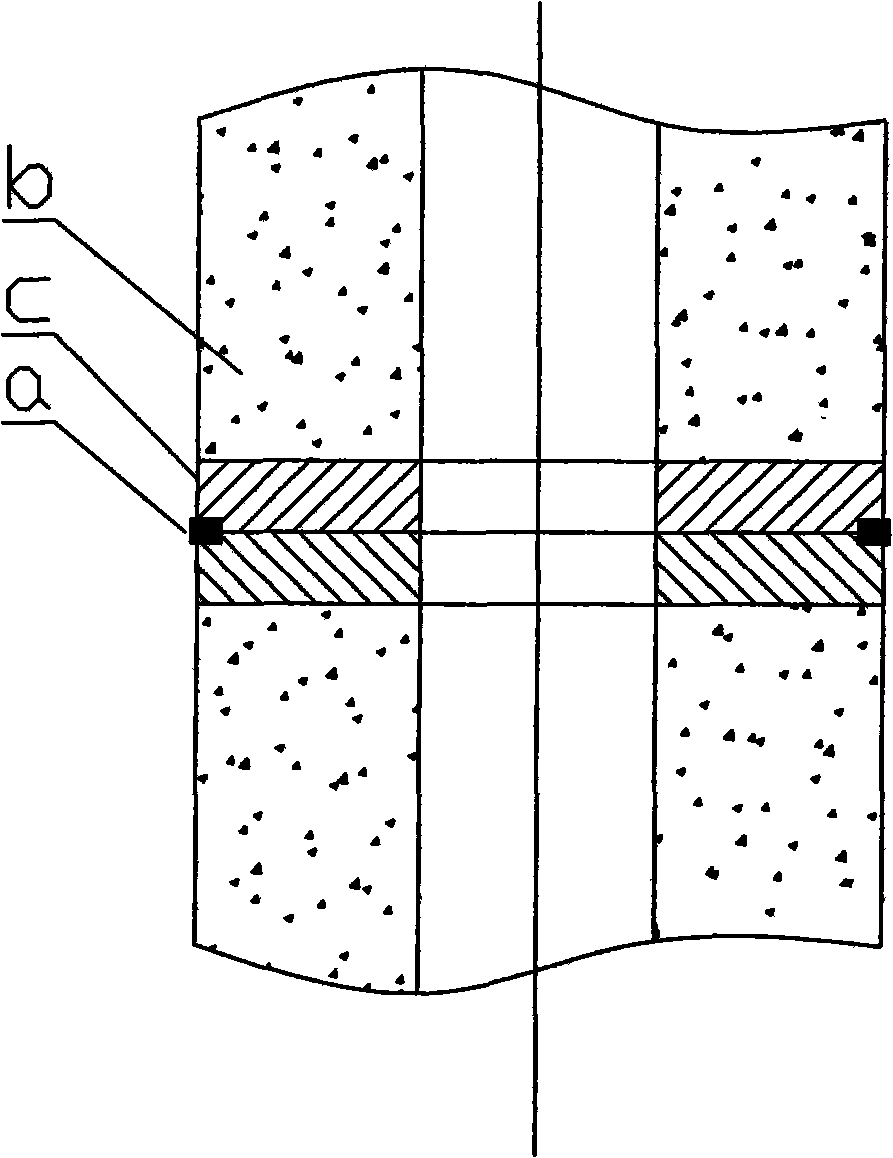

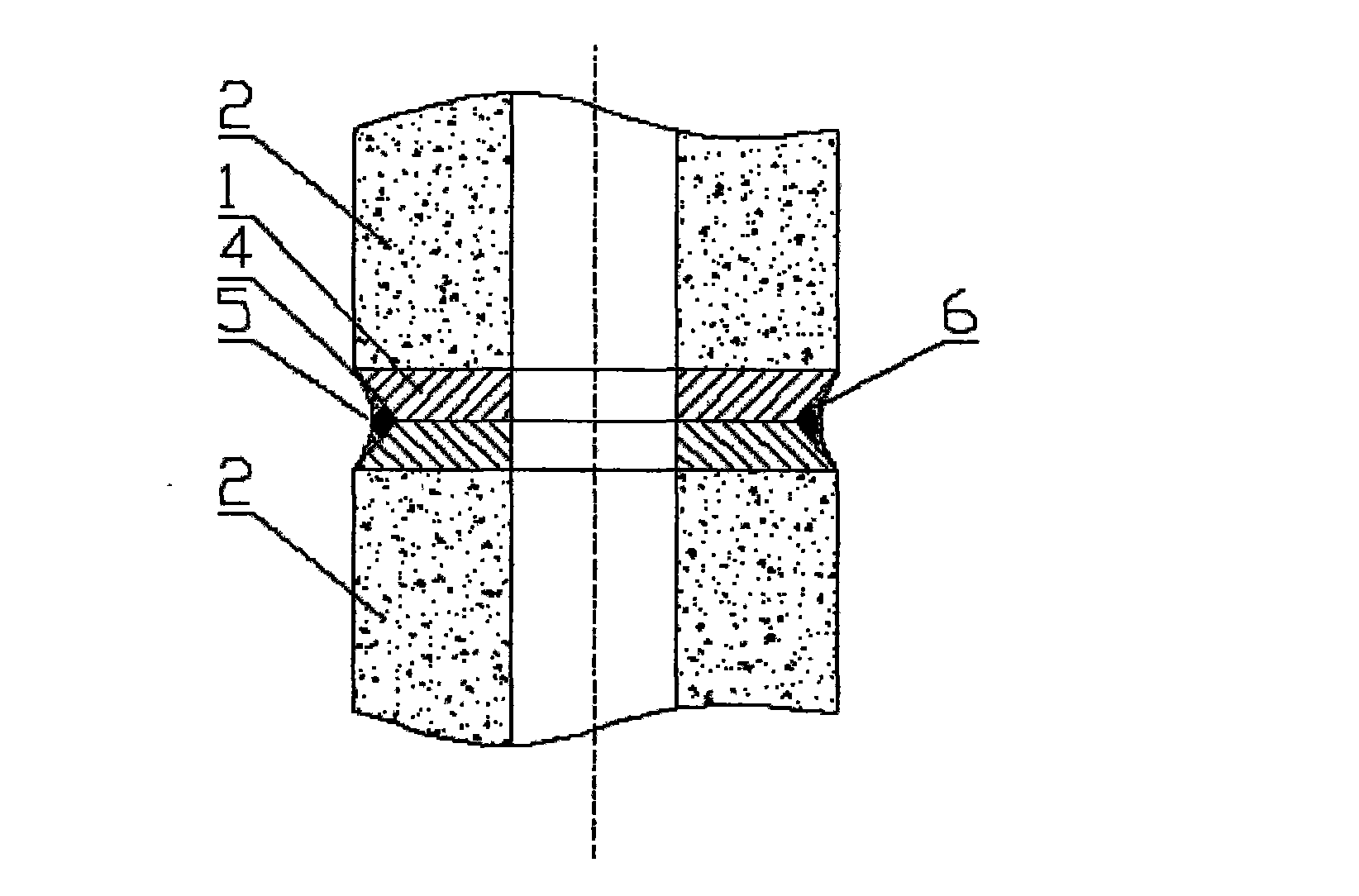

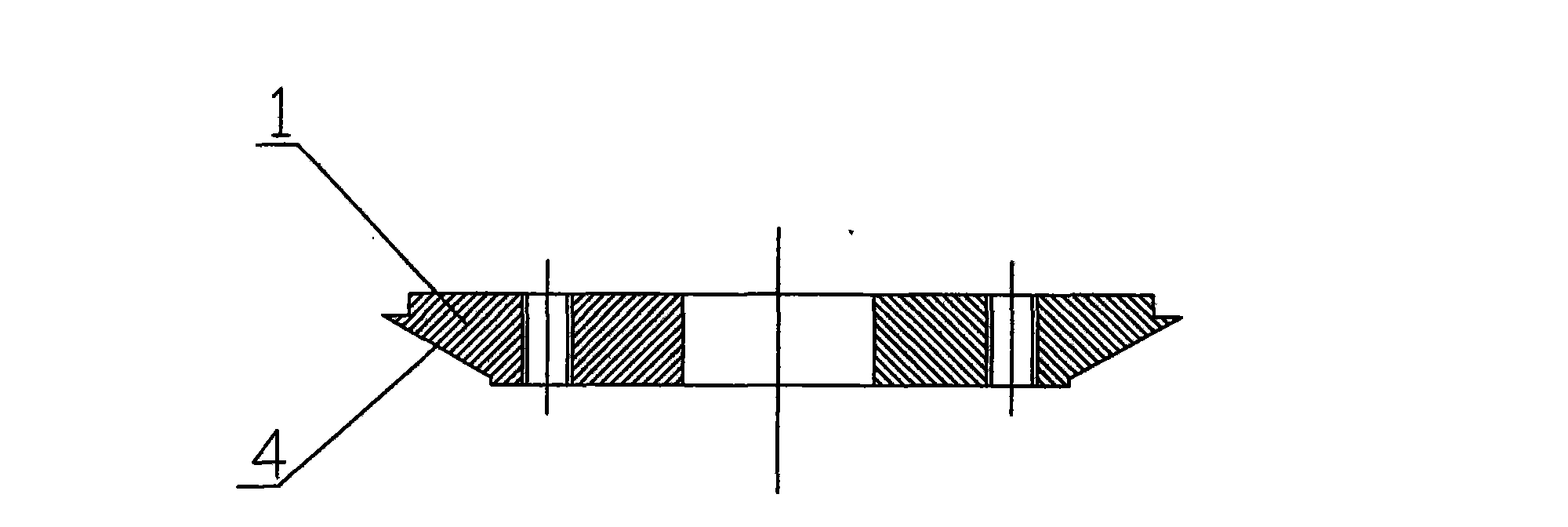

[0019] The corrosion-resistant prestressed concrete pipe pile foundation of the present invention, the cementitious material that the concrete that prepares pipe pile adopts is the granular micropowder material of different varieties and different finenesses; Wherein the micropowder material of different varieties is cement micropowder, ground fine sand micropowder Or ground quartz sand powder, granulated blast furnace water-quenched slag powder; the different fineness of the powder material is that the specific surface area of the cement powder is greater than 350m 2 / Kg and less than 380m 2 / Kg; the specific surface area of finely ground sand powder or ground quartz sand powder is greater than 380m 2 / Kg and less than 420m 2 / Kg; The specific surface area of granulated blast furnace water-quenched slag powder is greater than 430m 2 / Kg and less than 480m 2 / Kg; the specific surface area of ultra-fine powder of red mud by low-alkali sintering method is greater than...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com