High-temperature resistance tackifier for drilling fluid and preparation method thereof

A viscosifying agent and high temperature resistance technology, applied in the field of petroleum drilling fluid, to achieve the effect of maintaining and protecting oil and gas layers, reducing bentonite content and maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Add 100g of starch, 50g of guar gum, 10ml of propylene oxide and 600ml of water into a three-neck flask, stir for 10 minutes, then add a sodium hydroxide solution made of 10g of sodium hydroxide and 30ml of water, and heat in a water bath at 10°C React at ~70°C for 2 hours, then discharge, then dry and pulverize to obtain the finished product.

Embodiment 2

[0012] Add 100g of starch, 40g of guar gum, 20ml of epichlorohydrin, 10ml of ethanol and 500ml of water into the three-necked bottle, stir for 20 minutes, then add the potassium hydroxide solution made of 18g of potassium hydroxide and 60ml of water, and put it in a water bath Heating the pot and reacting at 65°C to 120°C for 3 hours, then discharging, drying and crushing at 100°C to obtain the finished product.

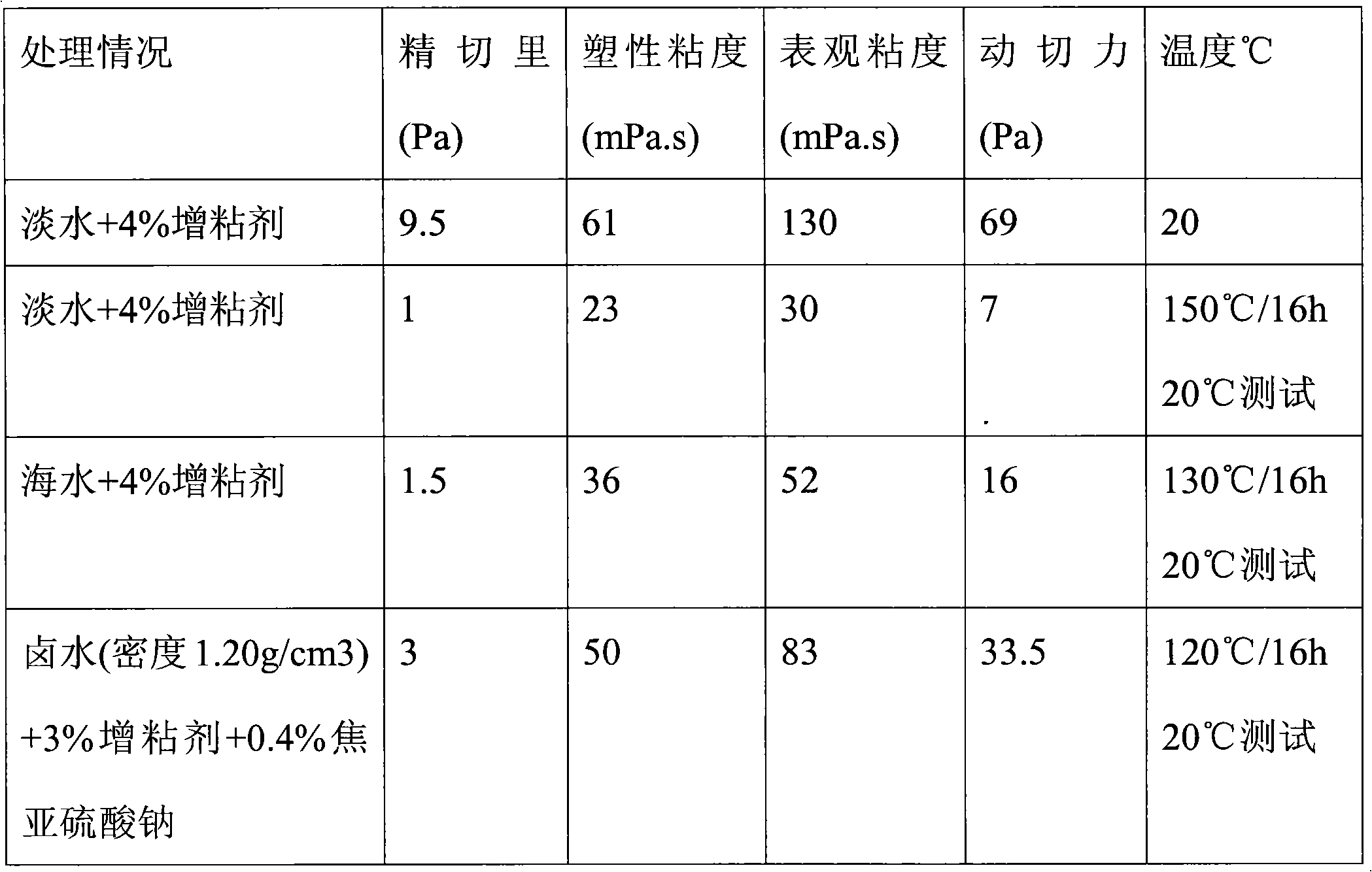

[0013] The temperature-resistant viscosity-increasing performance of the high-temperature-resistant tackifier prepared in embodiment 1 and embodiment 2 in fresh water, seawater, brine is shown in the following table:

[0014]

[0015] The high temperature resistant tackifier prepared in Example 1 and Example 2 has a temperature resistance of 150°C in fresh water, a temperature resistance of 130°C in seawater, and a temperature resistance of 120°C in brine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com