Al-Zn-Mg alloy and preparation method thereof

A technology of aluminum-zinc-magnesium and its manufacturing method, which is applied in the field of aluminum-zinc-magnesium alloy and its preparation, and can solve problems such as difficulty in meeting requirements for hubs, limited strength and toughness at room temperature, and low strength of high-toughness magnesium alloys.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

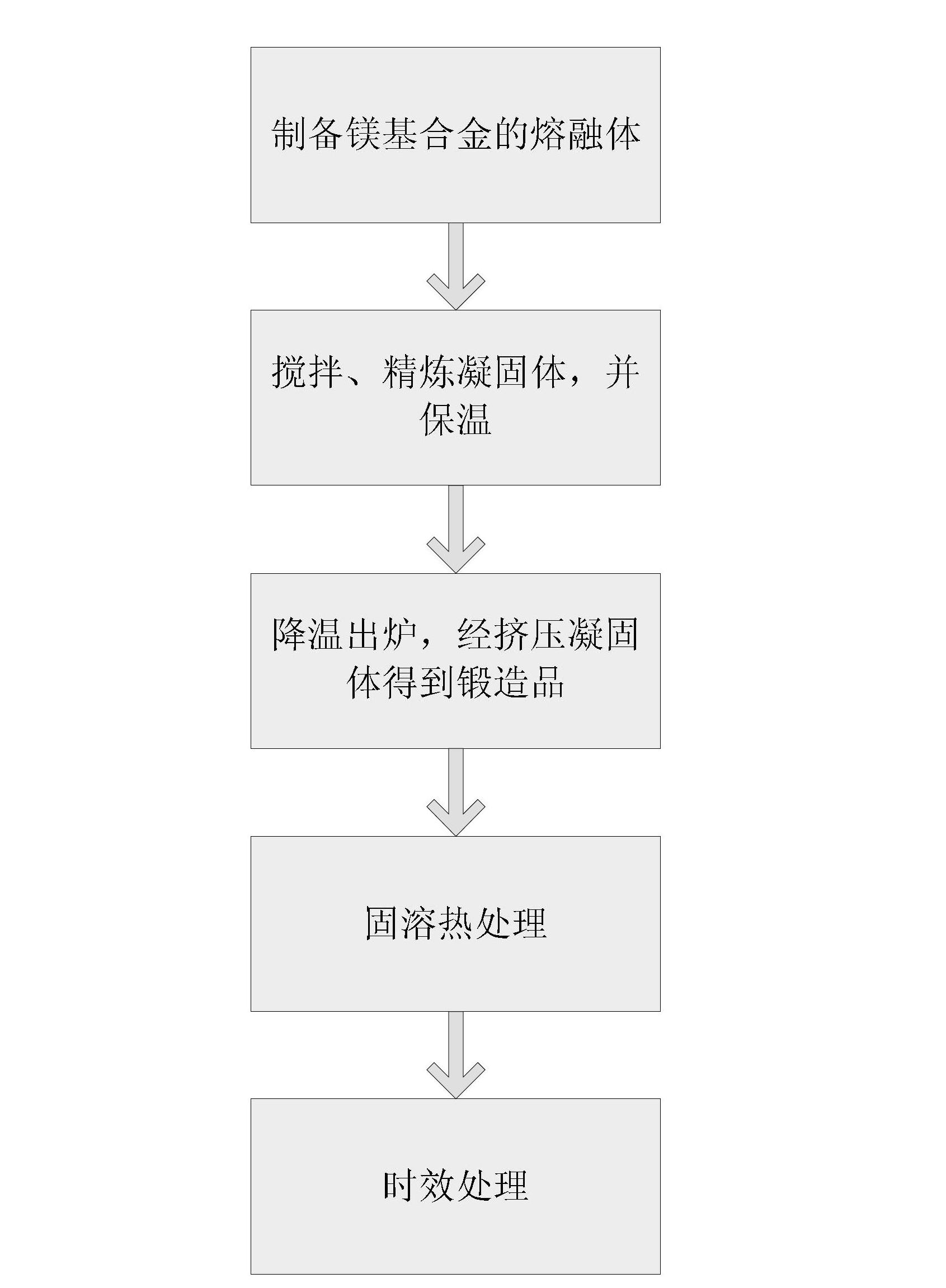

Image

Examples

Embodiment 1

[0075] A method for preparing an aluminum-zinc-magnesium alloy, comprising the steps of:

[0076] (a) Prepare a molten body of magnesium-based alloy, the molten body is composed of the following: 3wt% zinc, 3wt% aluminum, 0.9wt% titanium, 0.07wt% zirconium, 0.11wt% rhenium, 92.92wt% magnesium, and the rest also include Other unavoidable impurities; according to the formula, put the preheated alloy ingot into the crucible for melting to obtain a solidified body, and the melting temperature is 700°C;

[0077] (b) Heating up to 750°C, stirring and refining the solidified solid for 4 minutes, stopping stirring, and standing for 20 minutes;

[0078] (c) cooling down to 650°C, and then extruding the solidified body to obtain a forged product, the extrusion speed being 15mm / min;

[0079] (d) Install the furnace at 250°C, heat up to 350°C, keep warm for 2.2 hours, then continue to heat up to 450°C, hold for 22 hours, and quench in 50°C water after being out of the furnace; and

[00...

Embodiment 2

[0082](a) Prepare a melt of magnesium-based alloy, said melt is composed of the following: 1wt% zinc, 9wt% aluminum, 0.5wt% titanium, 0.14wt% zirconium, 0.02wt% rhenium, 89.34wt% magnesium, and the rest also include Other unavoidable impurities; according to the formula, put the preheated alloy ingot into the crucible for melting to obtain a solidified body, and the melting temperature is 650°C;

[0083] (b) heating up to 705°C, stirring and refining the solidified solid for 10 minutes, stopping the stirring, and standing for 16 minutes;

[0084] (c) cooling down to 650°C, and then extruding the solidified body to obtain a forged product, the extrusion speed being 150mm / min;

[0085] (d) Install the furnace at 280°C, heat up to 320°C, keep warm for 4 hours, continue to heat up to 400°C, keep warm for 17 hours, and quench in 80°C water after coming out of the furnace; and

[0086] (e) Aging treatment: first place at 20°C for 7h, then at 150°C for 4h, and finally at 120°C for 6...

Embodiment 3

[0088] A method for preparing an aluminum-zinc-magnesium alloy, comprising the steps of:

[0089] (a) Prepare a melt of magnesium-based alloy, according to the formula: zinc 3wt%, aluminum 3wt%, titanium 0.9wt%, zirconium 0.07wt%, rhenium 0.11wt%, yttrium 0.14wt%, manganese 0.03wt%, strontium 0.23wt% %, 0.02wt% niobium, including 92.4wt% magnesium, and the rest are unavoidable impurities. The preheated alloy ingot is put into a crucible for melting to obtain a solidified body, and the melting temperature is 667°C;

[0090] (b) heating up to 705°C, stirring and refining the solidified solid for 10 minutes, stopping the stirring, and standing for 16 minutes;

[0091] (c) cooling down to 650°C, then extruding the solidified body to obtain a forged product, the extrusion speed being 120mm / min;

[0092] (d) Install the furnace at 263°C, raise the temperature to 333°C, continue to heat up to 445°C after holding for 3 hours, hold for 20 hours, and quench in water at 62°C after comin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com