Precise solar energy glass laser scribing method

A solar glass, laser scribing technology, applied in laser welding equipment, electrical components, climate sustainability, etc., can solve the problem of low parallelism yield between lines, and achieve the effect of improving parallelism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical means adopted by the present invention to achieve the intended invention purpose are further described below in conjunction with the drawings and preferred embodiments of the present invention.

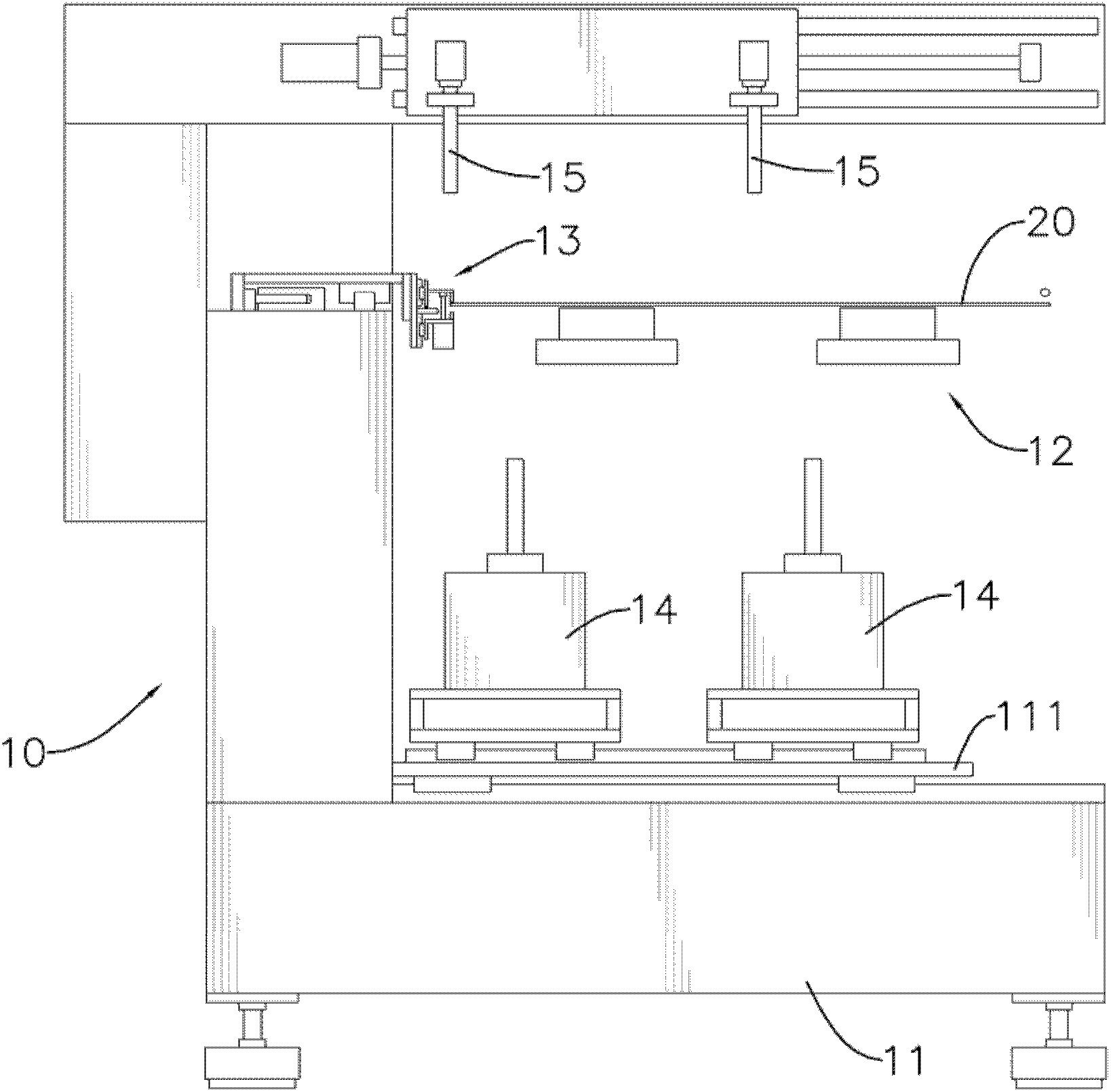

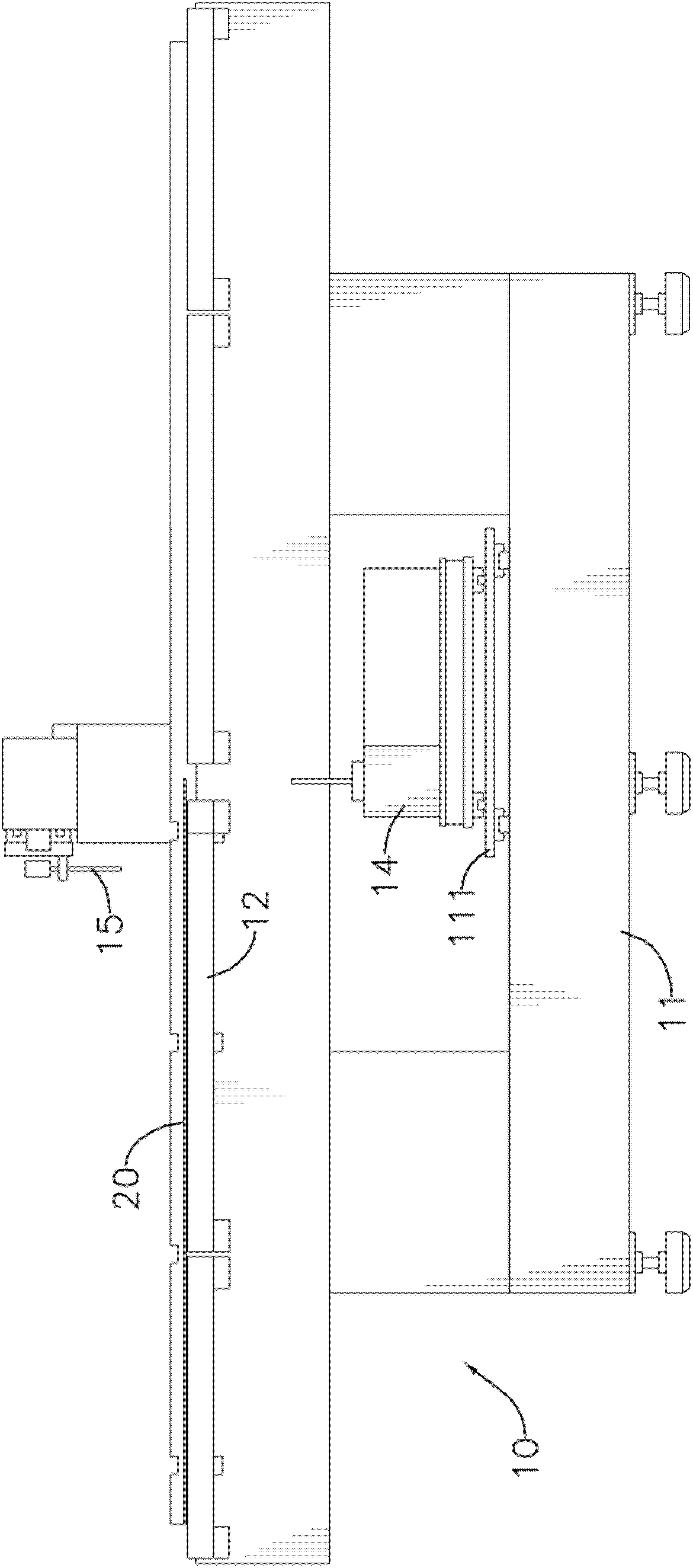

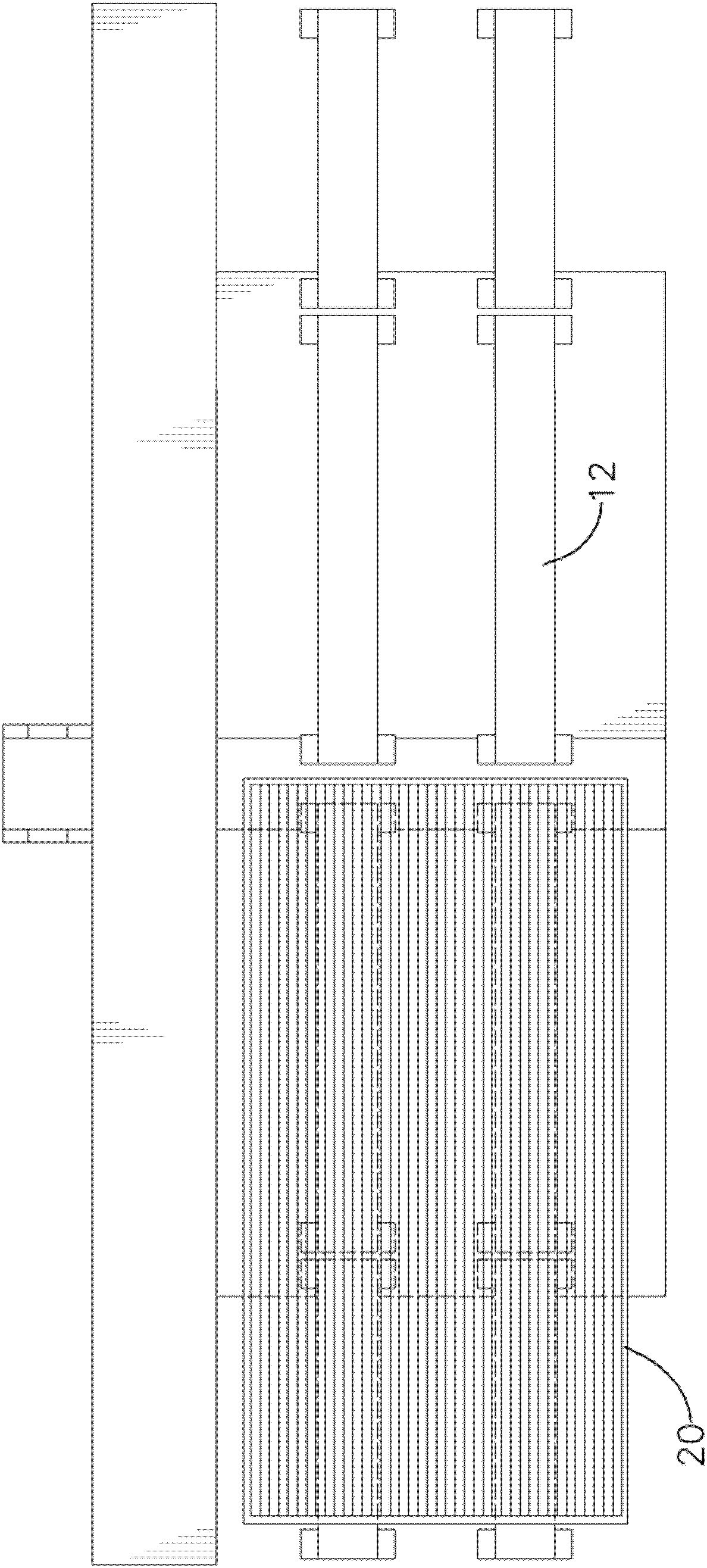

[0024] see Figure 1 to Figure 3 As shown, the high-precision solar glass laser scribing method of the present invention is achieved by using a laser scribing device 10. The laser scribing device 10 includes a machine 11, an air-floating platform 12, a clamping mechanism 13, at least A laser scribing device 14 and at least one visual alignment device 15: a mobile platform 111 is provided on the machine platform 11, and the mobile platform 111 can move back and forth in one direction on the machine platform 11; the air floating platform 12 is erected on Above the machine 11, a substrate 20 to be processed by laser scribing is located above the air flotation platform 12, and the substrate 20 is supported by the gas generated by the air flotation platform 12, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com