Adjustment method of multifunctional glass support platform

An adjustment method and the technology of the bearing platform, which are applied to glass manufacturing equipment, glass cutting devices, manufacturing tools, etc., can solve the problems of inaccuracy, inconvenient glass positioning, and inconvenient adjustment of the perpendicularity of the relative laser beam, so as to reduce the processing cost, The effect of good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

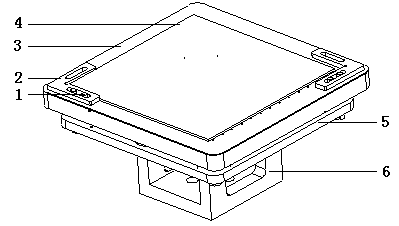

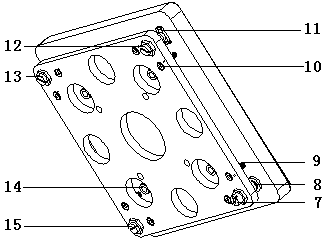

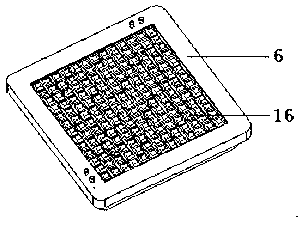

[0027] A multifunctional glass bearing platform, including a glass adjustment module, a glass vacuum adsorption module and a glass fast and precise positioning module; wherein, the glass adjustment module is a two-dimensional angle adjustment platform composed of double-layer flat plates, and the platform includes an upper flat plate and 1 lower plate, the surface of the upper plate has ventilation holes, the lower plate has three ball-headed adjusting screws and one flat-headed adjusting screw, and each adjusting screw is distributed with a connecting screw, and the connecting screw connects the upper plate and the lower plate The plates are fixedly connected into one; the glass vacuum adsorption module includes a glass fiber plate and an air suction device covered on the upper plate, and the glass fiber plate has a through hole at a position opposite to the air hole of the upper plate, and the glass fiber plate is positioned around The block is pressed on the upper plate, and...

Embodiment 2

[0036] A multifunctional glass bearing platform, including a glass adjustment module, a glass vacuum adsorption module and a glass fast and precise positioning module; wherein, the glass adjustment module is a two-dimensional angle adjustment platform composed of double-layer flat plates, and the platform includes an upper flat plate and 1 lower plate, the surface of the upper plate has ventilation holes, the lower plate has three ball-headed adjusting screws and one flat-headed adjusting screw, and each adjusting screw is distributed with a connecting screw, and the connecting screw connects the upper plate and the lower plate The plates are fixedly connected into one; the glass vacuum adsorption module includes a glass fiber plate and an air suction device covered on the upper plate, and the glass fiber plate has a through hole at a position opposite to the air hole of the upper plate, and the glass fiber plate is positioned around The block is pressed on the upper plate, and...

Embodiment 3

[0040] A multi-functional glass bearing table integrates vacuum adsorption function and glass positioning function into a precise two-dimensional angle adjustment platform. The glass carrying platform has three functions: vertical adjustment of the glass relative to the laser beam, vacuum adsorption of the glass, and precise positioning of the glass speed;

[0041] 1) The platform has a precision two-dimensional angle adjustment platform composed of a double-layer plate. The lower plate has 3 precision adjustment screws with ball head characteristics and 1 adjustment screw with flat head characteristics. A connecting screw is distributed at a certain angle, and the connecting screw connects the upper plate and the upper plate into a whole, and a spring is worn on the connecting screw part in the middle of the two platforms. Two of the three adjusting screws are directly in contact with the upper plate with the ball head, and the other one is in contact with the "V" shape forme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com