Heat capacity type neodymium glass bar-shaped laser

A neodymium glass and laser technology, which is applied in the field of lasers, can solve the problems of large and complex mechanical structures of lasers, and fail to reach the kilowatt level, and achieve the effects of light weight, simple and compact structure, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

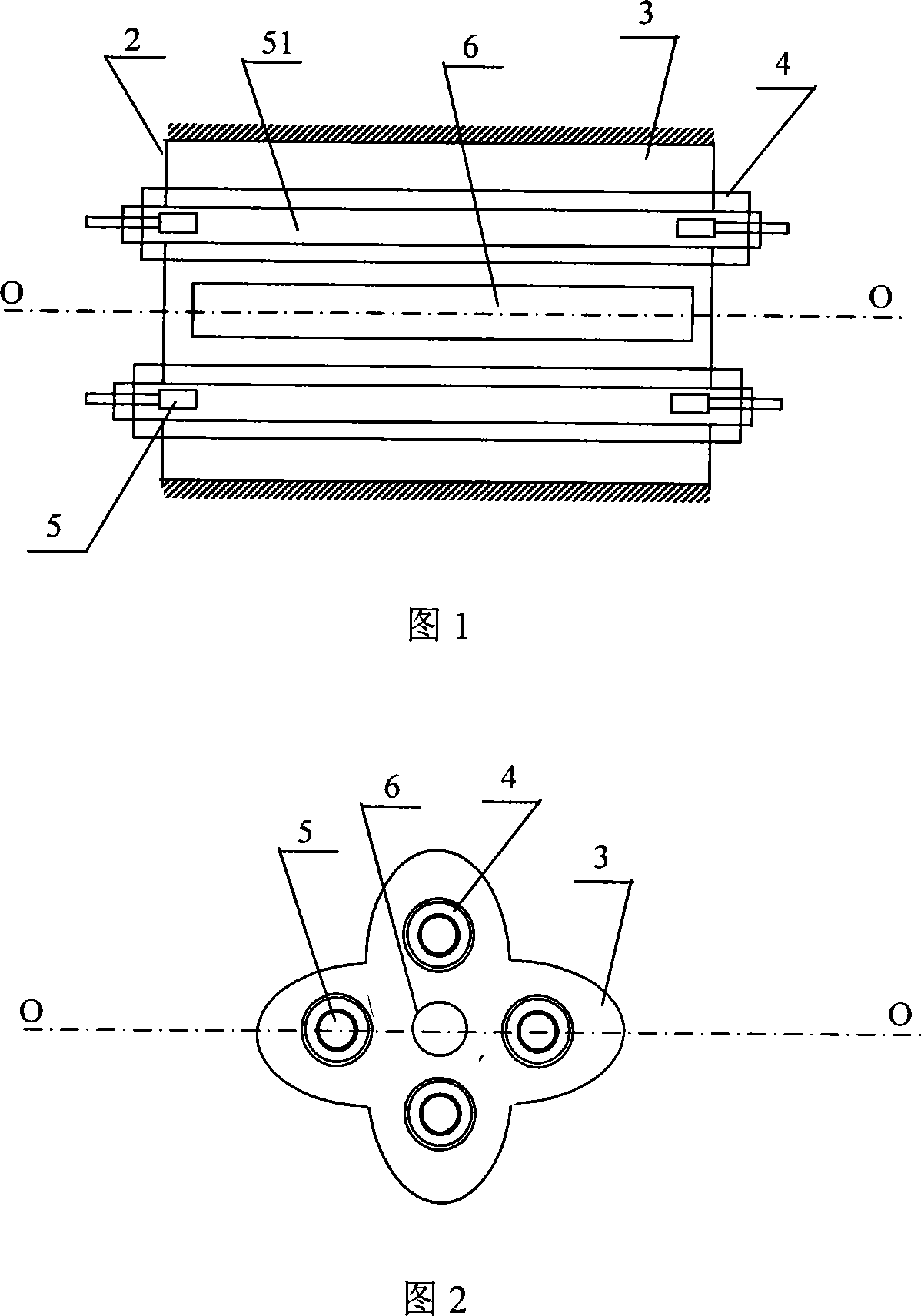

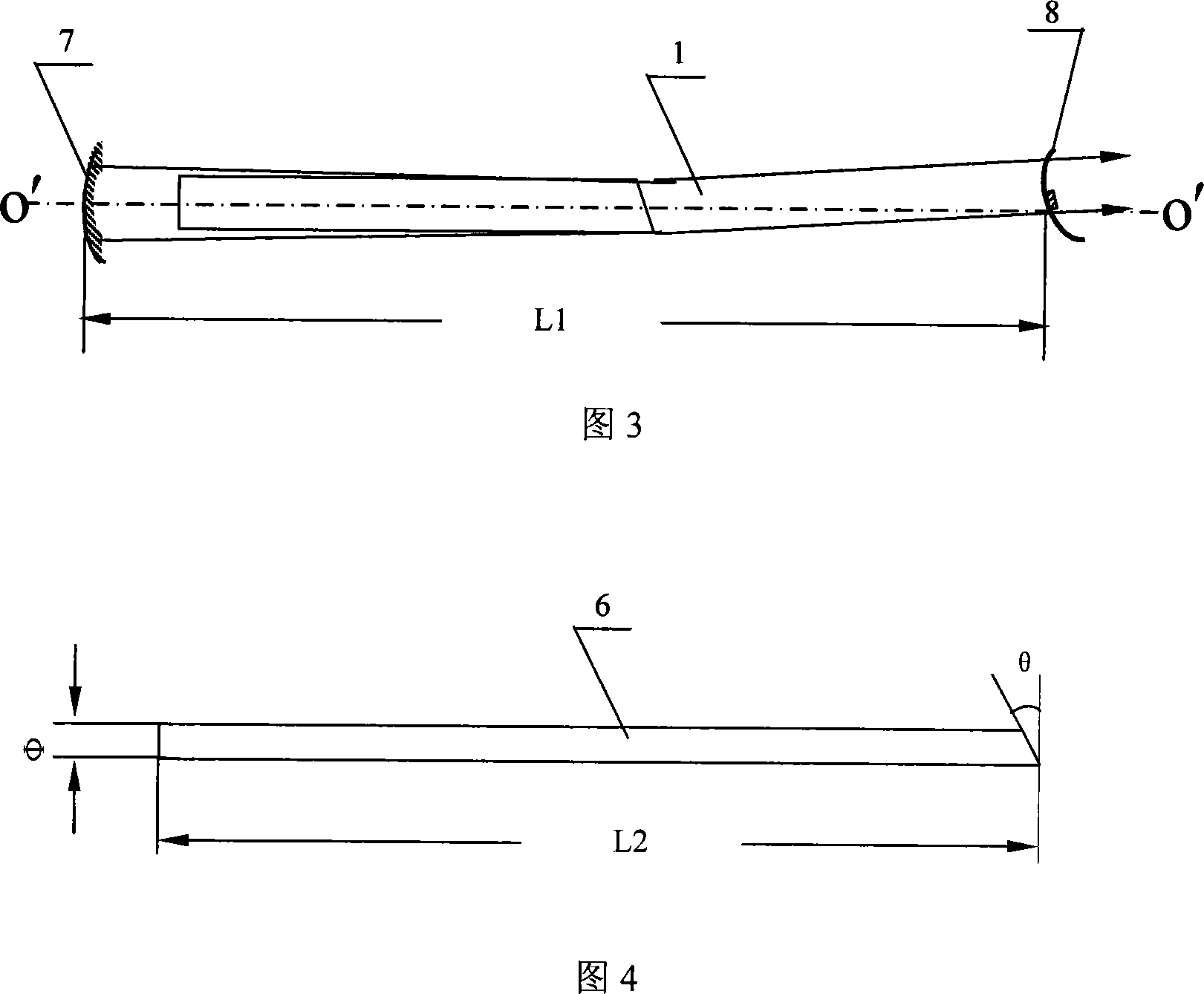

[0018] As shown in Fig. 1, Fig. 2 and Fig. 3, a heat-capacitive neodymium glass rod laser includes a resonant cavity 1, a concentrator 2 and a rod-shaped neodymium glass laser medium 6, and the optical axis O'O' of the resonant cavity 1 and The optical axis OO of the concentrator 2 and the axis of the rod-shaped neodymium glass laser medium 6 coincide in three lines. The resonant cavity 1 includes a total reflection mirror 7 and a half reflection mirror 8 . The concentrator 2 is in the shape of a quincunx and consists of four semi-elliptical concentrating cavities 3. A xenon lamp 5 parallel to the direction of the laser beam is arranged in the concentrating cavity 3, and a cooling tube 4 is placed outside the xenon lamp 5, and the cooling tube 4 is cerium-doped The quartz water cooling pipe is provided with flowing cooling water in the coolin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com