Tissue cooling rod for laser surgery

a technology of laser surgery and cooling rod, which is applied in the field of tissue cooling rod for laser surgery, can solve the problems of affecting the cooling effect of surgical instruments, affecting the treatment effect, and affecting the treatment effect, and achieves the effect of high heat conduction properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

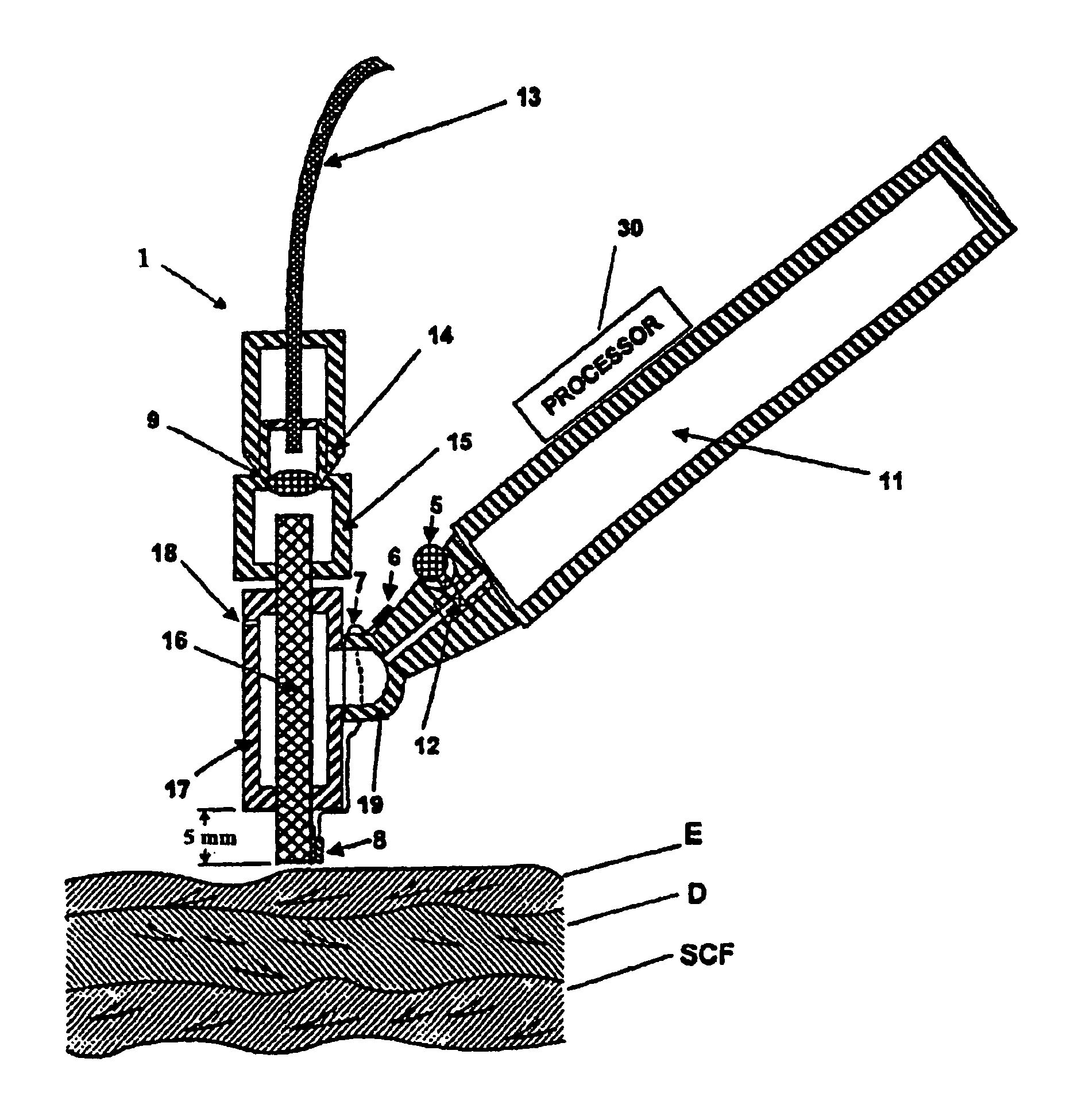

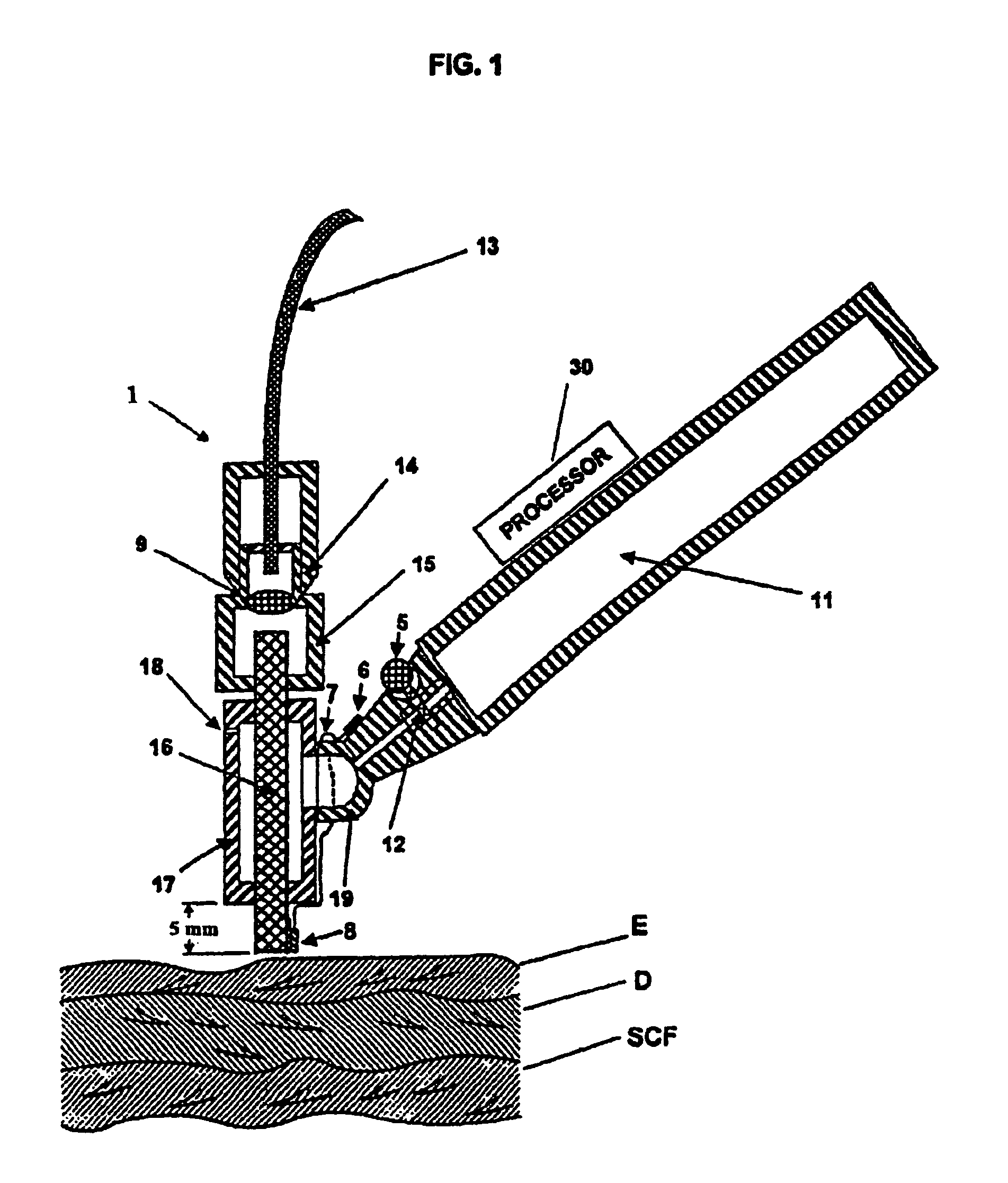

Image

Examples

second embodiment

[0044]A second embodiment involves the use of a cryogenically cooled diamond cooling element as shown in FIGS. 5A and 5B. The device consists of copper holder 24, which has a cryogenic container 21. Synthetic diamond cooling element 23 is in the shape of a flattened cylinder and contains a circular groove through which cryogenic mist flows. The mist exits at the exit port 26.

[0045]The flattened diamond rod is transparent to the laser beam. It is applied to the part of the cleaned skin to be treated. The nozzle valve opens the shutter and the cryogenic spray flows to the chamber around this window. When the window is cold the “ready” light will be switched-on. The energy delivery procedure can be started. This device is good for the large area irradiation such as subsurface tumor interstitial thermotherapy with a high frequency electromagnetic radiation.

PATERNED COOLING ELEMENT FOR MASKING PORTIONS OF TISSUE

third embodiment

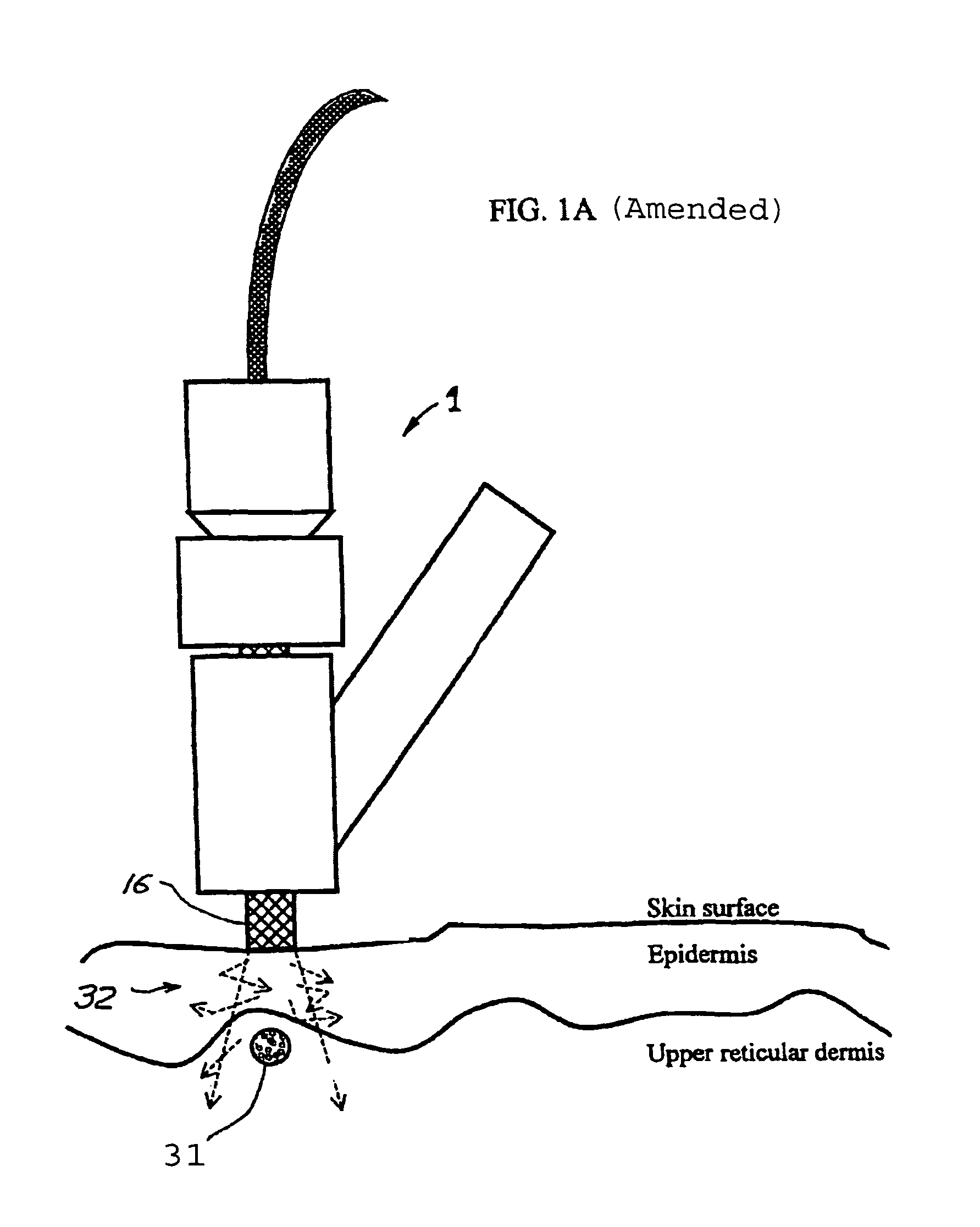

[0046]A third embodiment for practicing this invention is to use a patterned rod to the surface of the skin in order to have damaged and healthy areas under the skin surface. FIGS. 3A and 3B show rod 31 with the perpendicular grooves 32 filled with copper stripes 33.

[0047]A laser light is sent through the cooled rod to the surface of the skin does not penetrate through the copper stripes. But the contacting surface of the rod has an almost uniform temperature distribution. It means that the surface of the skin is cooled uniformly. But under skin damage is not uniform having irradiated and not irradiated healthy spots. The reason to have these healthy untouched spots around the damaged tissue is to use the capacity of healthy spot tissue and cells for the fast immune response and wound healing process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com