Novel high-power strip laser system

A slab laser, high-power technology, applied in the field of laser material surface treatment, laser radar and photoelectric countermeasures, laser processing, can solve the problems that affect the quality of laser output beam, unfavorable high-power amplification system, laser output non-uniformity, etc. Achieve the effects of improving the quality of the output beam, increasing the energy of light amplification, and avoiding the effect of thermally induced birefringence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

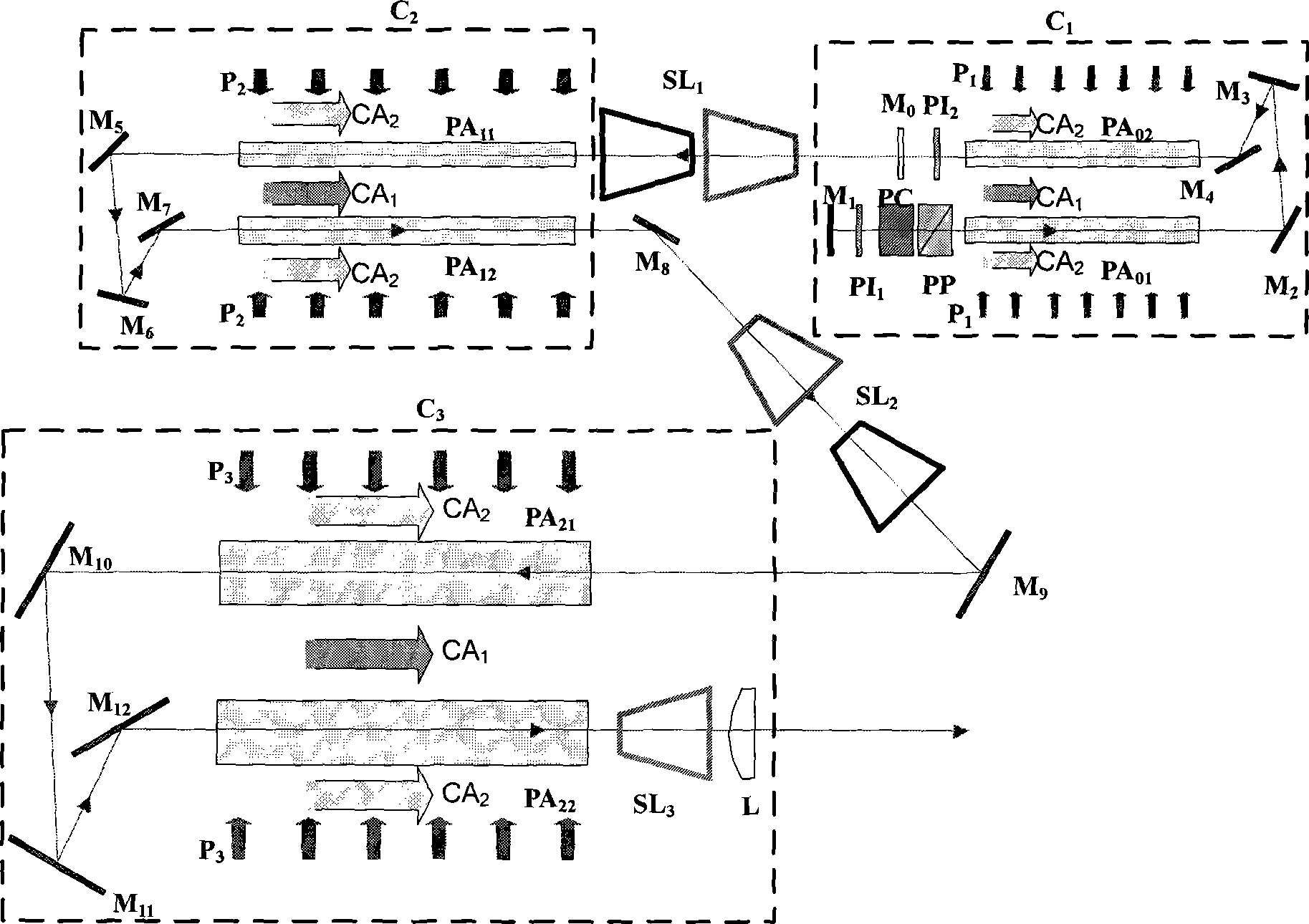

[0017] Combine below figure 1 The details and operation of the laser system proposed by the present invention are described in detail.

[0018] The invention mainly includes a laser cavity and an interstage beam expander compensation mirror, wherein the laser cavity is composed of a laser oscillator C 1 , pre-amplifier C 2 and main amplifier C 3 Consisting of three parts, the laser oscillator C 1 In the tightly hugging ceramic diffuse reflection cavity, place two parallel neodymium glass laser dielectric slabs PA with the same size, material and performance 01 and PA 02 , Slatted PA 01 and PA 02 The pumping source P composed of a large xenon lamp is placed in parallel on the outside 1 , in neodymium glass laser dielectric slab pa 01 and PA 02 One end is equipped with three total reflection mirrors M 2 , M 3 , M 4 A three-mirror retroreflective system composed of the first neodymium glass laser dielectric slab PA 01 The other end is provided with a total reflection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com