Glass laser-drilling machine capable of quick cooling

A glass laser and rapid cooling technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of relatively high requirements for operators, reduce economic benefits, increase costs, etc., to reduce operation difficulty and reduce production costs cost, productivity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with drawings and embodiments.

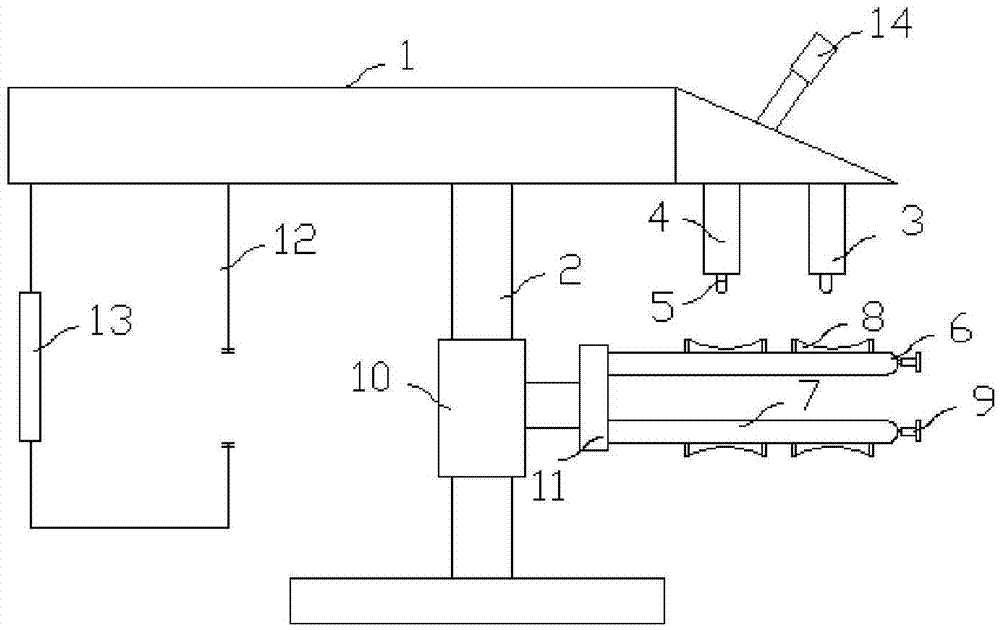

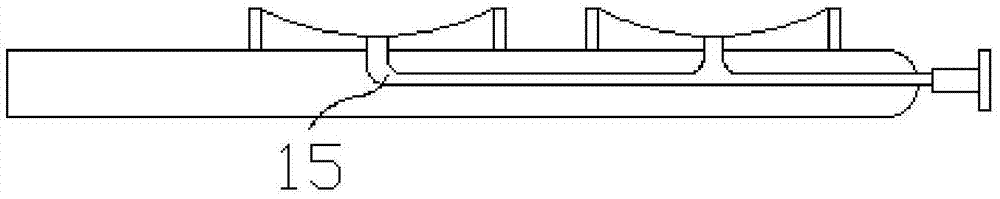

[0016] like Figure 1-2 As shown, a rapidly cooling glass laser drilling machine includes a fixed frame 2 fixed to the bottom of the connecting arm 1, and a first laser welding head 3 and a second laser welding head 4 are arranged in parallel at the bottom of one end of the connecting arm 1, The bottom ends of the first laser welding head 3 and the second laser welding head 4 are all provided with a condenser lens 5, and the bottoms of the first laser welding head 3 and the second laser welding head 4 are provided with a first fixed arm 6 and a second fixed arm in parallel. 7. Two suction cups 8 are provided on the surfaces of the first fixed arm 6 and the second fixed arm 7, one end of the first fixed arm 6 and the second fixed arm 7 are connected to the surface of the turntable 11, and the other end of the turntable 11 is fixed on the The surface of the rotating shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com