Method for annealing stress of prestressed glass laser

A glass laser and prestressing technology, applied in the field of laser processing, laser processing of tempered glass and semi-tempered glass, can solve the problem that prestressed glass cannot be processed subsequently.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

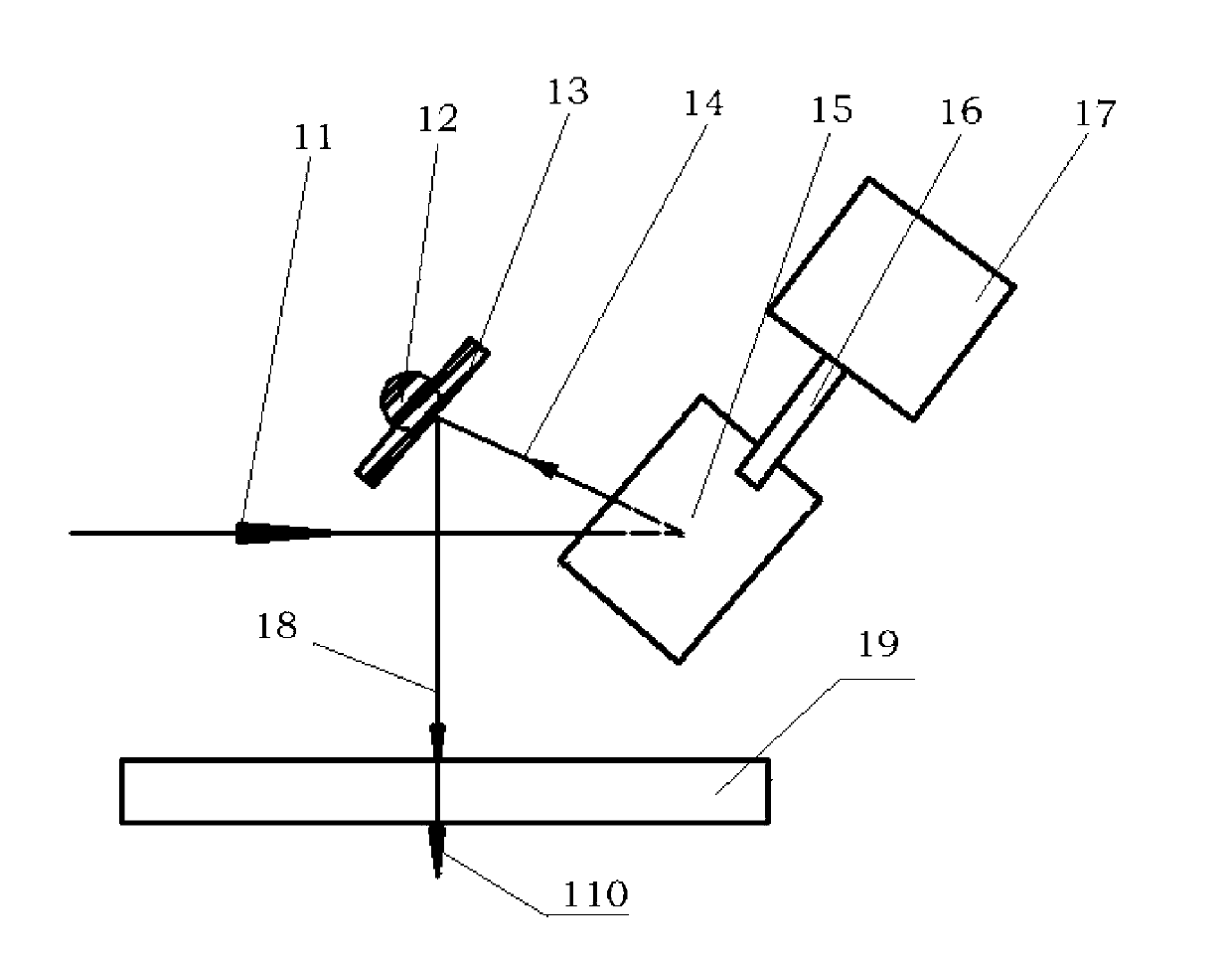

[0028] Example 1: figure 1 It is a schematic structural diagram of the laser stress relief device for laser drilling of chemically tempered glass in embodiment 1, by figure 1 It can be seen that: the initial collimated incident laser beam 11 is reflected by the first galvanometer lens 15, and its reflected beam 14 is reflected by the second galvanometer lens 13 to obtain a reflected laser beam 18, and the reflected laser beam 18 is injected into the chemically tempered glass 19, except Part of the laser light is absorbed, and part of the laser light is transmitted through the chemically tempered glass 19 to obtain a transmitted light beam 110 .

[0029] The collimated incident laser beam 11 is used to heat the chemically tempered glass 19, also known as heating laser. The heating laser is a continuous carbon dioxide gas laser with a wavelength of 10.6 microns, an average power of 50 W, a fundamental mode, and a collimated incident laser beam diameter of 2 mm.

[0030]The fir...

Embodiment 2

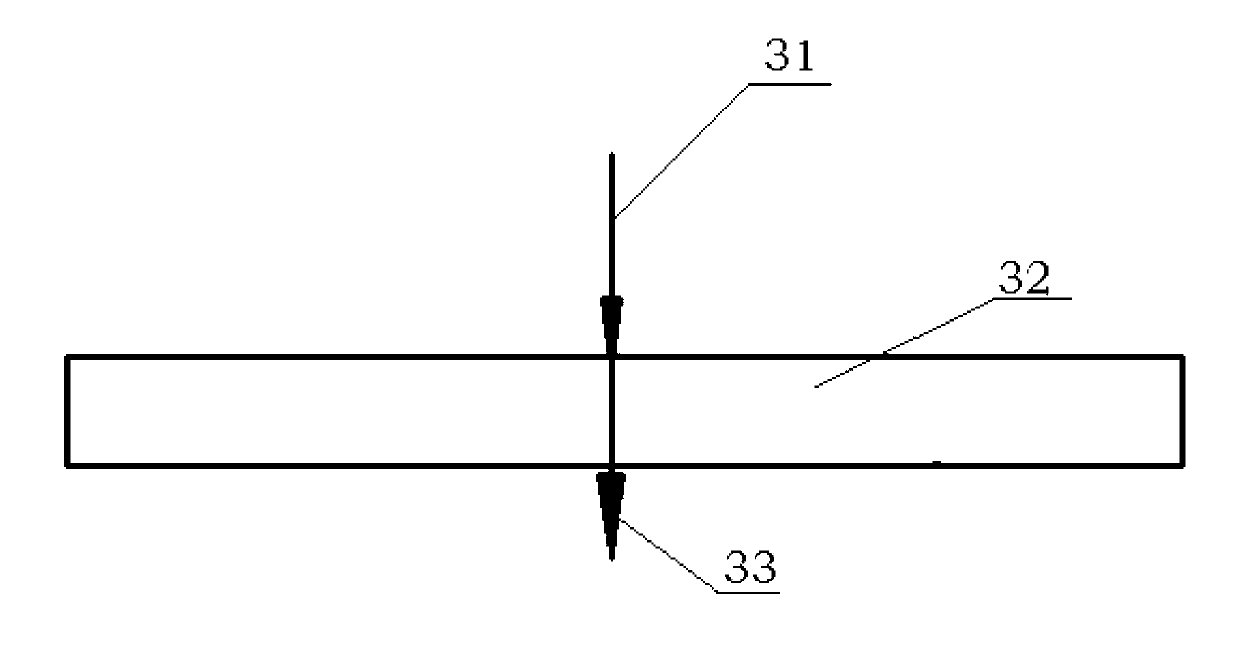

[0042] image 3 It is a structural schematic diagram of the laser stress relief device for laser cutting of chemical tempered glass in embodiment 2, by image 3 It can be seen that when the collimated incident laser beam 31 passes through the chemically toughened glass 32 , part of the laser light is absorbed, and part of the laser light is transmitted through the chemically toughened glass 32 to obtain a transmitted beam 33 .

[0043] The collimated incident laser beam 31 is used to heat the chemically tempered glass 32, which is called heating laser. The heating laser is a continuous carbon dioxide gas laser with a wavelength of 10.6 microns, an average power of 50 watts, a fundamental mode, and a collimated incident laser beam 31 with a beam diameter of 2 mm.

[0044] The thickness of the chemically tempered glass 32 is 0.8 mm, and the tempering depth of the upper and lower surfaces is 70 microns.

[0045] The collimated incident laser beam 31 moves in a straight line fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com