Method and device for detecting impurities and defects of tempered glass curtain wall

A technology of tempered glass and glass curtain wall, which is applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of small glass samples, save energy, save energy and test funds, and ensure the safety of people's lives and properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

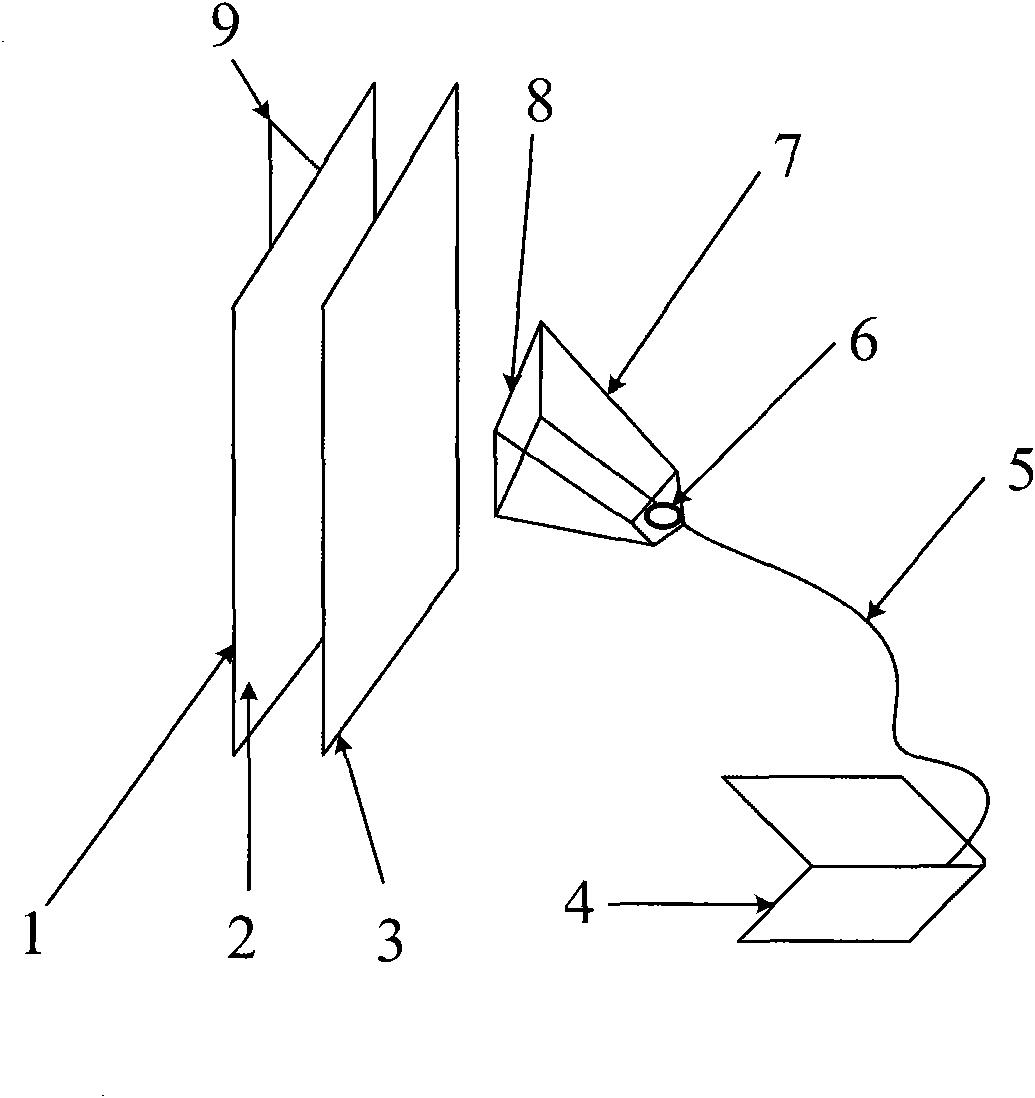

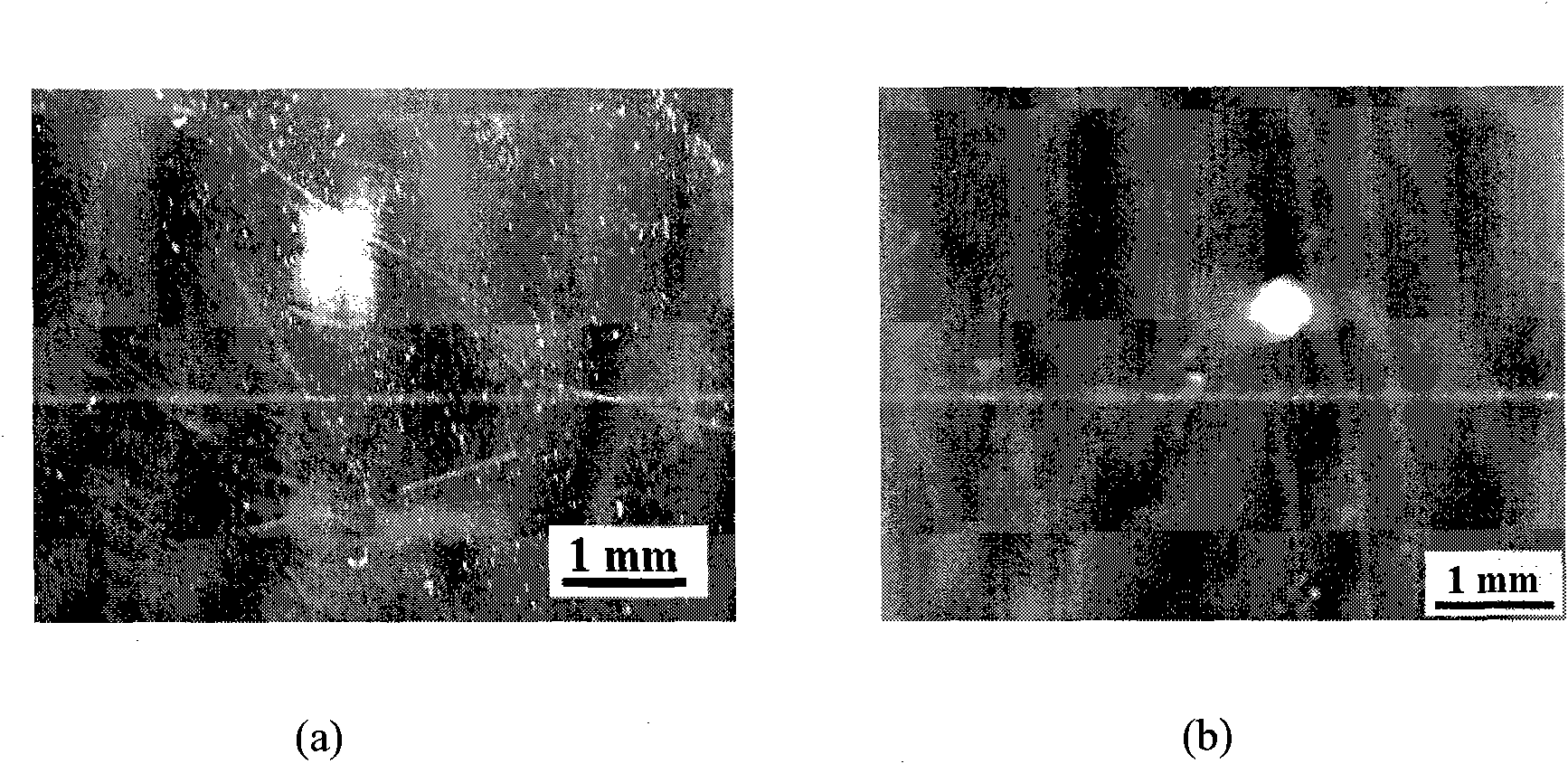

[0031] The invention uses transmitted cross polarized light to detect impurities and defects in curtain wall glass in service. The invention mainly adopts natural light as incident light, and determines the type, size and position of impurities or defects in the curtain wall glass by analyzing the measured stress stripe distribution.

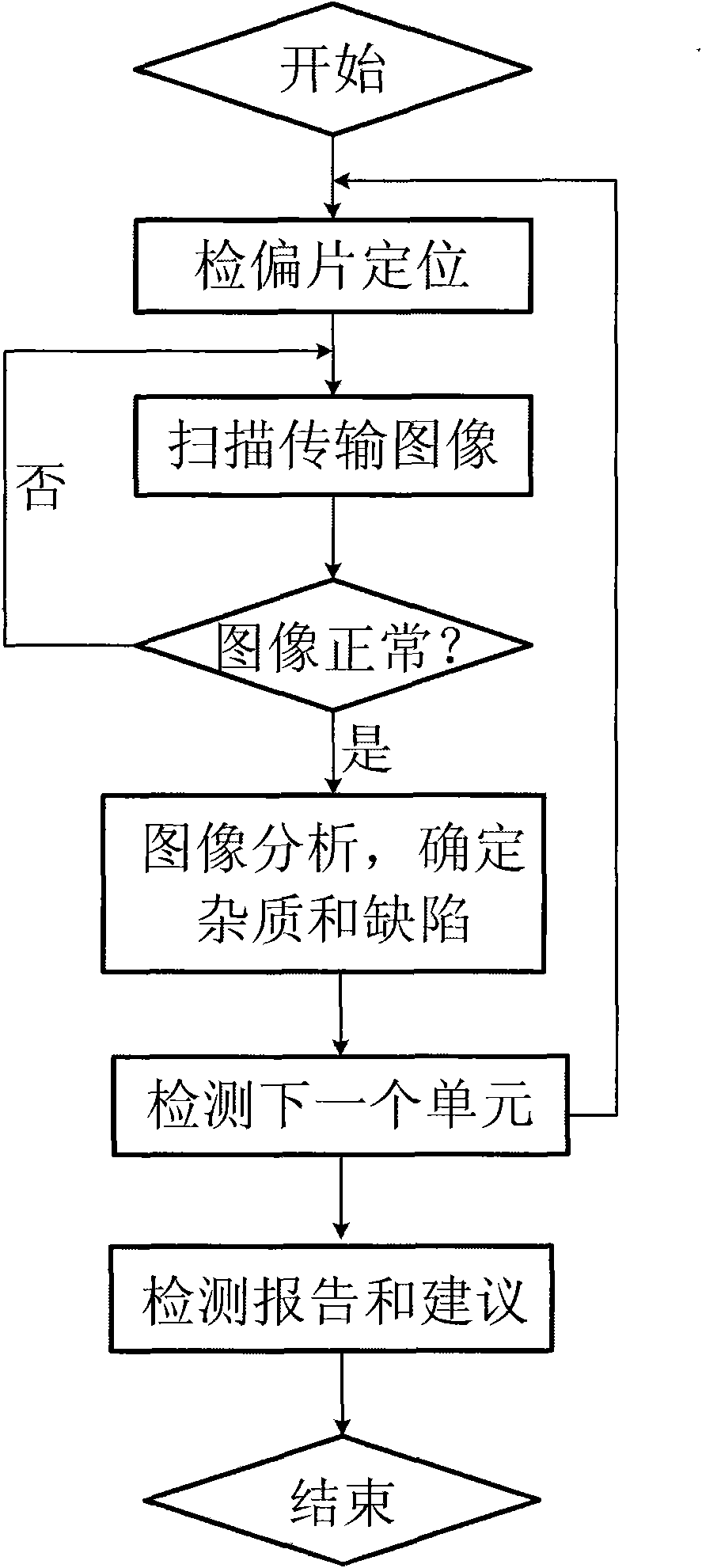

[0032] The method for detecting impurities and defects in the existing glass curtain wall in the present invention is divided into the following steps:

[0033] 1) Hang and place a large plexiglass plate with a polarizer on the outside of the curtain wall glass of a certain unit, with the frosted plexiglass facing outward, and the side with the polarizer facing towards the curtain wall glass side;

[0034] 2) Place a dark box equipped with an analyzer at a place facing the glass of the curtain wall by hand or with an automatic drive device, and scan the entire glass curtain wall in blocks;

[0035] 3) Utilize the digital video camera installed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resolution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com