Sealing-in method for glass and kovar alloy and sealed body

A technology of alloy and glass, which is applied in the field of connection of heterogeneous materials, can solve the problems of mismatch of thermal physical properties of glass and alloy, decrease of joint strength, low joint strength, etc., to adapt to flexible manufacturing environment, high processing efficiency, and improve use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

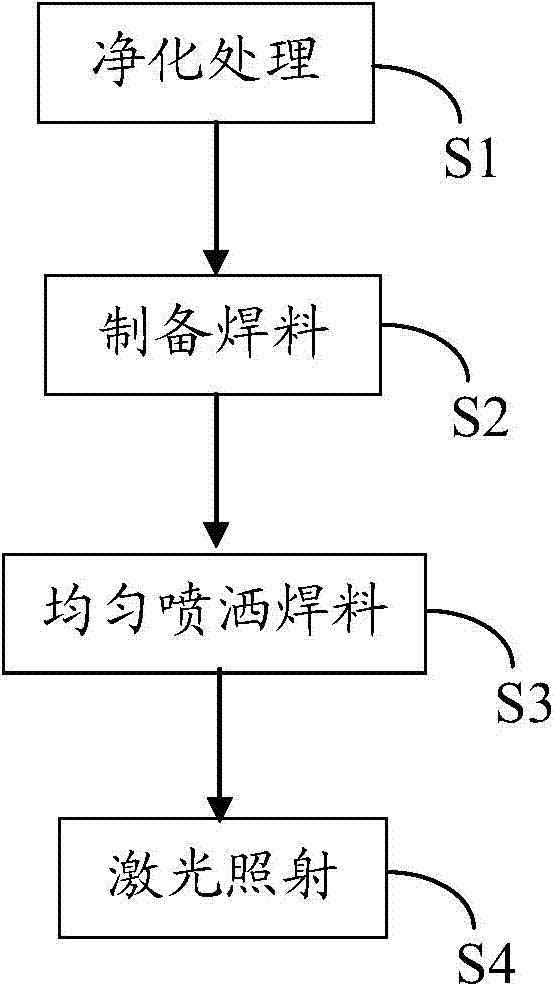

Method used

Image

Examples

Embodiment 1

[0040] Clean the window glass sample with a size of 8×20×4mm (length×width×thickness), and degrease and degrease the Kovar alloy steel plate with a size of 10×25×1.5mm (length×width×thickness) . Then oxidize the Kovar alloy steel plate. During the oxidation treatment, the oxidation treatment temperature was controlled at 700° C. and kept for 10 minutes, and the thickness of the formed oxide layer was controlled at 3 μm.

[0041] Mix 90% glass powder with 10% Kovar powder and mix in a ball mill for 4 hours. After taking it out, keep it in a vacuum oven at 200°C for 2 hours, and form solder with the furnace cooling, take it out and set it aside. Among them, the glass powder includes the following components according to the mass percentage: 50.81% SiO2 , 8.05% CaO, 33.55% Na 2 O. The particle size is 150 mesh. The particle size of glass powder and kovar alloy powder is 150 mesh.

[0042] In an argon atmosphere, evenly spray the solder on the surrounding edges of the metal ...

Embodiment 2

[0046] Clean the window glass sample with a size of 8×20×4mm (length×width×thickness), and degrease and degrease the Kovar alloy steel plate with a size of 10×25×1.5mm (length×width×thickness) . Then oxidize the Kovar alloy steel plate. During the oxidation treatment, the oxidation treatment temperature was controlled at 800° C. and kept for 20 minutes, and the thickness of the formed oxide layer was controlled at 7 μm.

[0047] The glass powder with a mass fraction of 99% was mixed with 1% Kovar alloy powder and mixed in a ball mill for 7 hours. After taking it out, keep it in a vacuum oven at 200°C for 3 hours, and form solder with the furnace cooling, take it out and set it aside. Among them, the glass powder includes the following components according to the mass percentage: 28.75% SiO 2 , 13.84% CaO, 46.21% Na 2 O. The particle size of glass powder and kovar alloy powder is 200 mesh.

[0048] Under the argon atmosphere, the solder is evenly sprayed on the surroundin...

Embodiment 3

[0052] Clean the window glass sample with a size of 8×20×4mm (length×width×thickness), and degrease and degrease the Kovar alloy steel plate with a size of 10×25×1.5mm (length×width×thickness) . Then oxidize the Kovar alloy steel plate. During the oxidation treatment, the oxidation treatment temperature was controlled at 780° C. and kept for 18 minutes, and the thickness of the formed oxide layer was controlled at 5.5 μm.

[0053] Mix glass powder with a mass fraction of 95% and Kovar powder with a mass fraction of 5%, and mix them in a ball mill for 7 hours. After taking it out, keep it in a vacuum oven at 200°C for 5 hours, then cool down in the furnace to form solder, and take it out for use. Wherein the glass powder comprises the following components by mass percentage: 50% SiO 2 , 10% CaO, 40% Na 2 O. The particle size of the glass powder is 180 mesh, and the particle size of the Kovar alloy powder is 190 mesh.

[0054] Under the argon atmosphere, the solder is even...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com