Multi-camera correcting and positioning method and glass laser cutting device

A positioning method and cutting device technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of poor precision, slow CNC processing speed, poor effect, etc., achieve high precision, reduce the difficulty of calculation, reduce Effects of Computational Errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

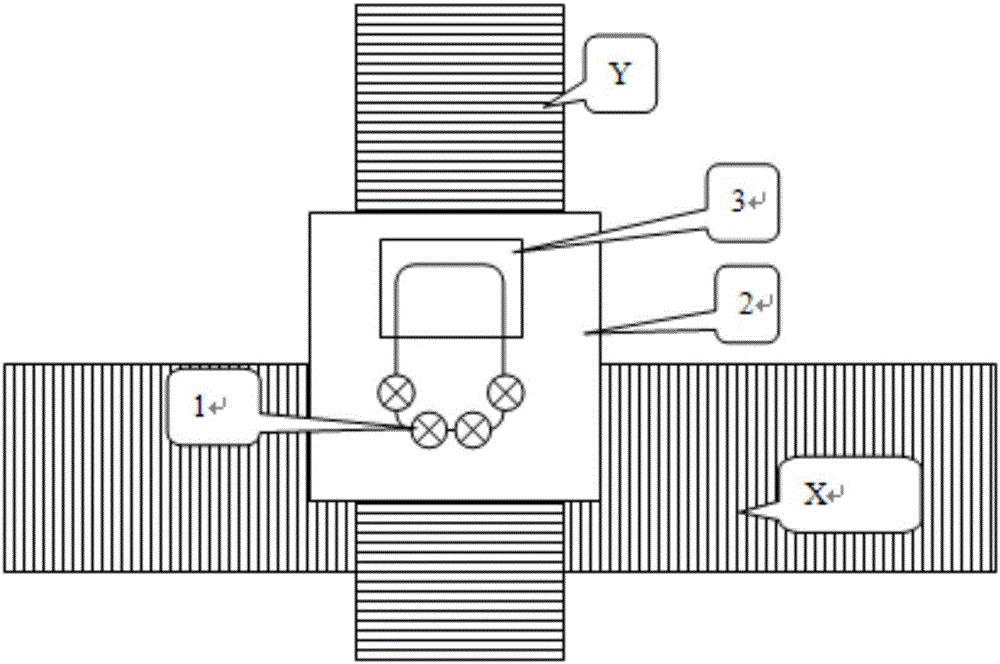

[0029] A multi-camera correction and positioning method and a glass laser cutting device according to the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0030] The following is a best example of a multi-camera correction and positioning method and a glass laser cutting device described in the present invention, which does not limit the protection scope of the present invention.

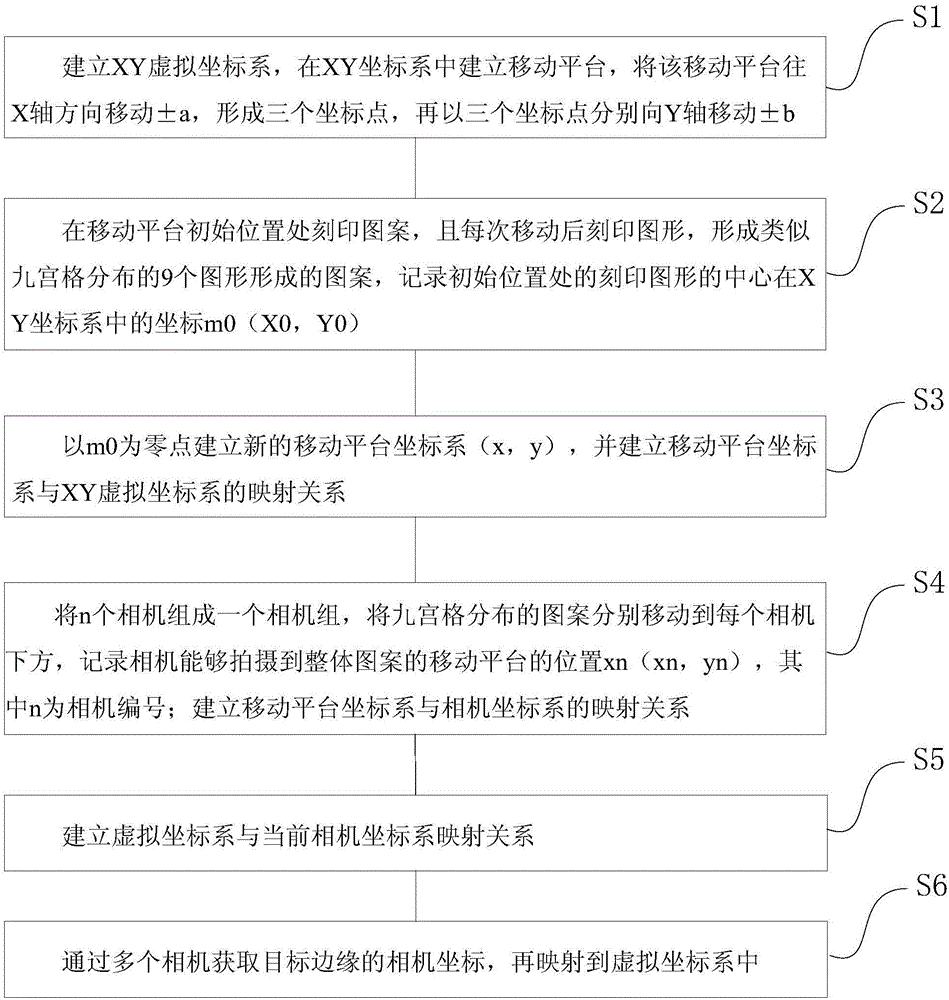

[0031] figure 1 A multi-camera correction and positioning method is shown, including the following steps:

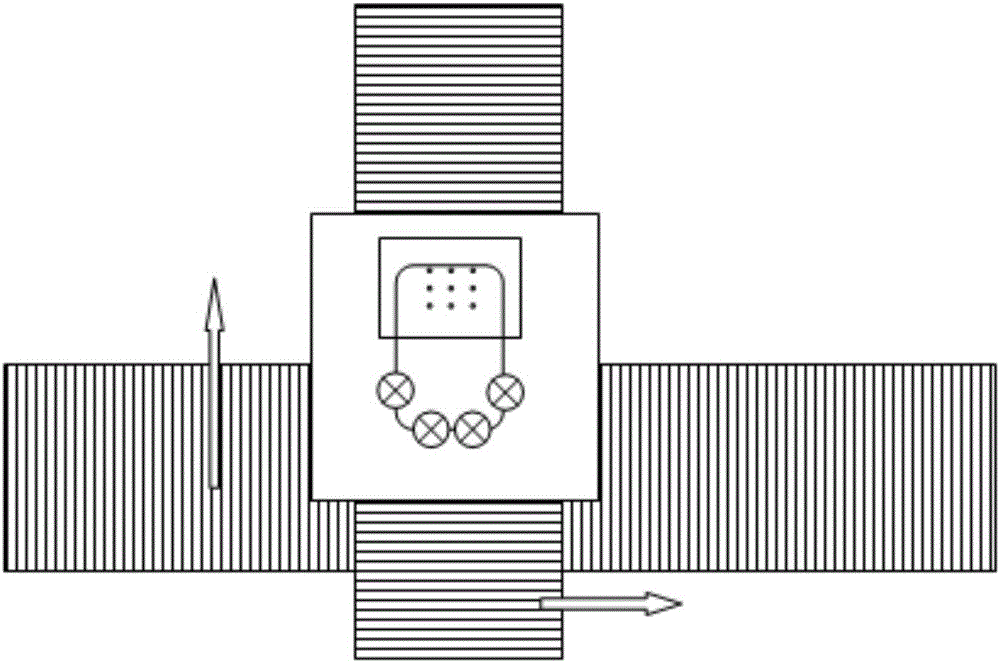

[0032] S1. Establish an XY virtual coordinate system, establish a mobile platform in the XY coordinate system, move the mobile platform to the middle position, and move the mobile platform to the X-axis direction ±a to form three coordinate points, and then use the three coordinate points respectively Move ±b to the Y axis;

[0033] S2. Engraving a pattern at the initial position of the mobile platform, and engraving a circle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com