Laser chamfering method and equipment for glass

A glass laser and chamfering technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as low product yield, glass edge cracking, glass secondary pollution, etc., and achieve high product yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

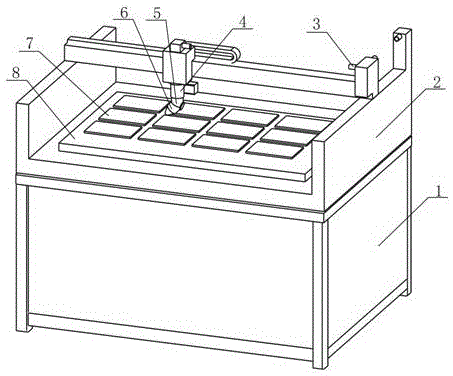

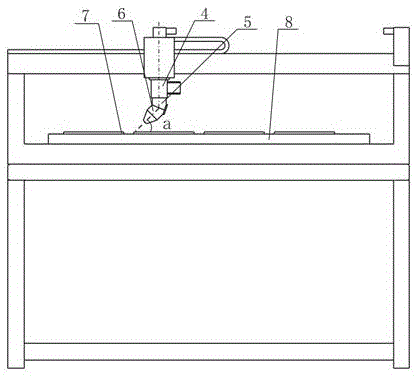

[0023] figure 2 Explanation of marks: Rack 1, two-dimensional motion platform 2, optical path system 3, rotation mechanism 4, swing angle mechanism 5, focus mechanism 6, glass 7, adsorption platform 8.

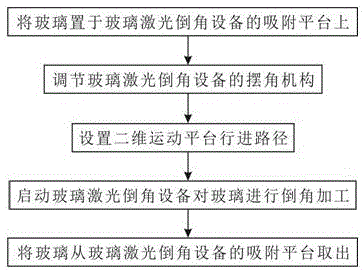

[0024] see figure 1 and figure 2 , an embodiment of the glass laser chamfering method of the present invention comprises the following steps:

[0025] ①. Put the glass 7 on the adsorption platform 8 of the glass laser chamfering equipment, and use the adsorption platform 8 to facilitate the fixing and removal of the glass 7;

[0026] ②. Adjust the swing angle mechanism 5 of the glass laser chamfering equipment, so that the angle between the axis of the laser beam output from the focusing mechanism 6 of the glass laser chamfering equipment and the glass 7 is equal to the required degree of cutting chamfering. In general, All the chamfers of a piece of glass 7 are the same, and in the embodiment, the angle adjustment of the pendulum mechanism 5 adopts manual adjustment;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com