Glass material feeding method and device for controlling and regulating glass flow rate

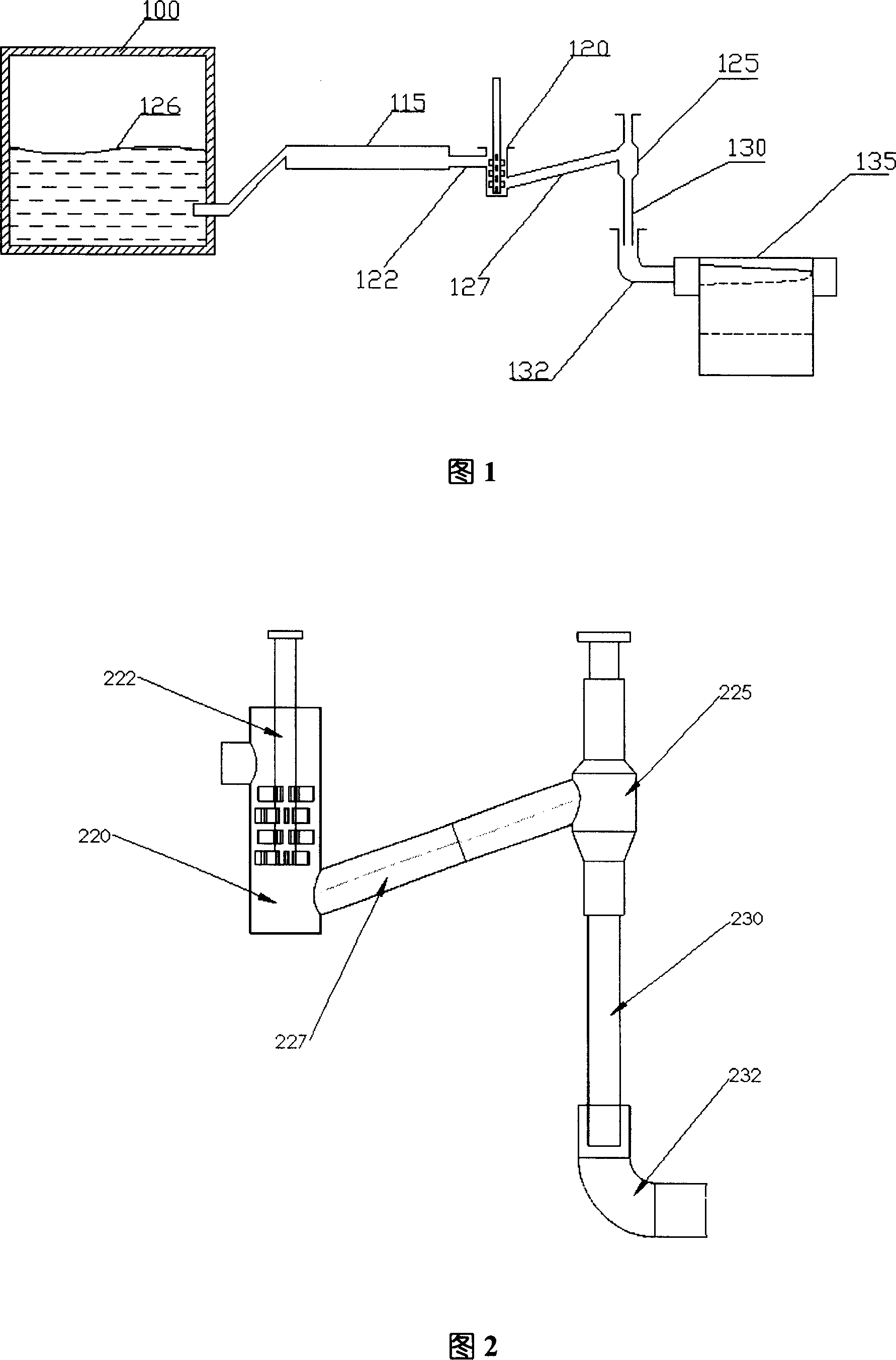

A feeding device and glass technology, applied in feeding machine nozzles, glass production, etc., to achieve the effect of stabilizing temperature and reducing glass defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

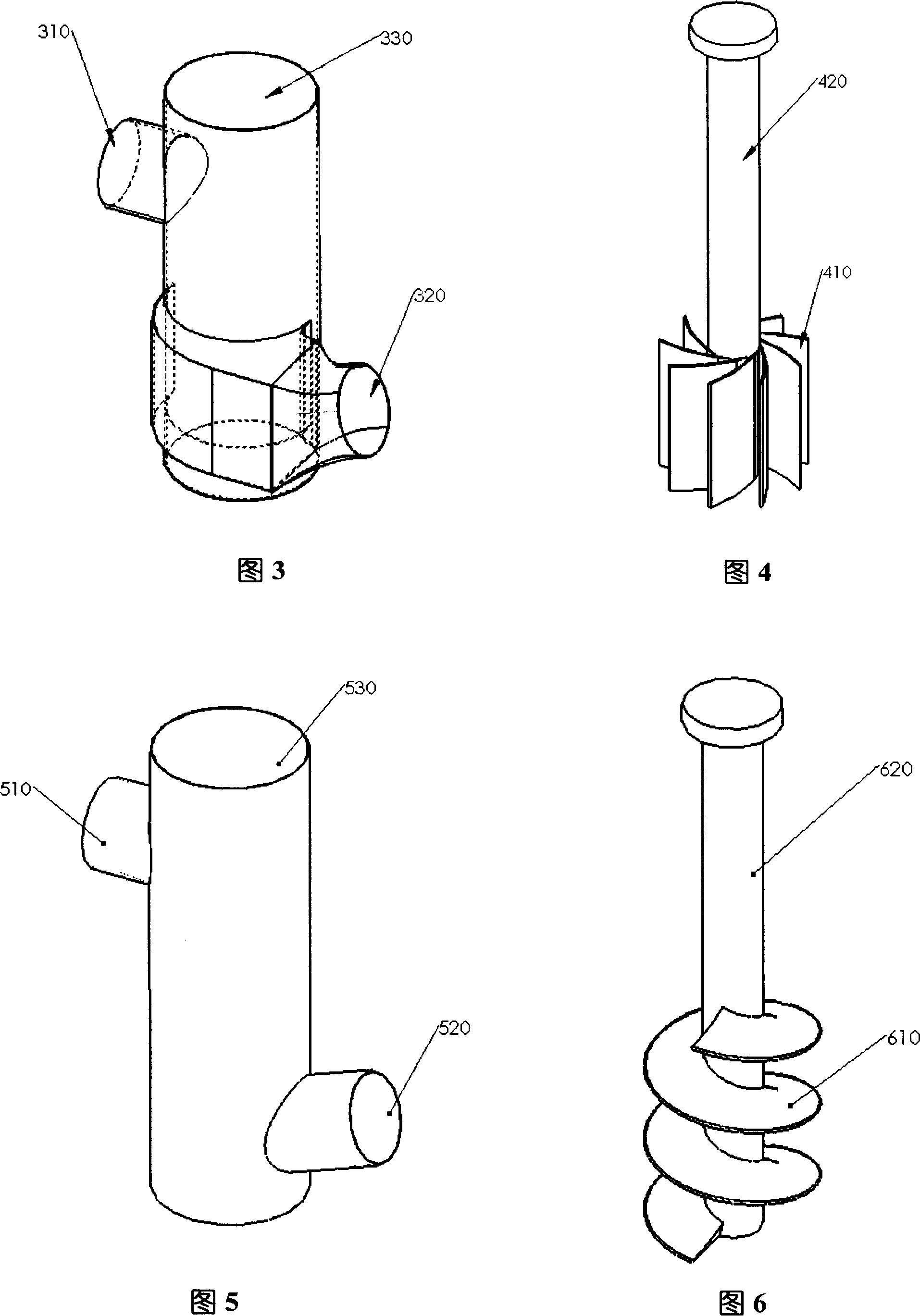

Embodiment 1

[0035] The stirred tank in the first embodiment of the present invention is centrifugal, and it has an inlet and an outlet, and the central axis of the outlet is tangent to the inner wall of the stirred tank, as shown in Figure 3 . The agitator has multiple blades, and the blades are in the shape of a turbine, as shown in Figure 4. The molten glass flows in from the inner edge of the impeller and flows out from the outer edge through the blade flow channel. Then the energy obtained by the unit weight of the fluid after being stirred by the stirrer is:

[0036] H e = QN 60 g ( 1 b 2 tan α 2 - 1 b ...

Embodiment 2

[0045] As shown in Figures 5 and 6, in another embodiment of the present invention, the stirring tank is the same as the stirring tank in the prior art, and the blades of the stirrer are helical.

[0046] Introduce the alkali-free molten glass in the patent CN200510007338.0 into the feeding system shown in the present invention, the stirring tank and the agitator in the feeding system in this embodiment are the stirring tank and the agitator shown in Figure 5 and Figure 6 respectively ; In the agitator shown in Figure 6, the outer diameter of the blade is 220mm, and the central axis shaft diameter is 70mm, and the helix angle is 15 °, and the diameter D of the pipe connecting the stirring tank and the material bowl c =150mm, length L along the cooling pipe c =2000mm, equivalent diameter of stirring tank D st =250mm, the height L of the molten glass in the stirring tank st =500mm; the diameter of the drop tube D x =220mm, glass flow length L x = 400mm. The glass viscosity ...

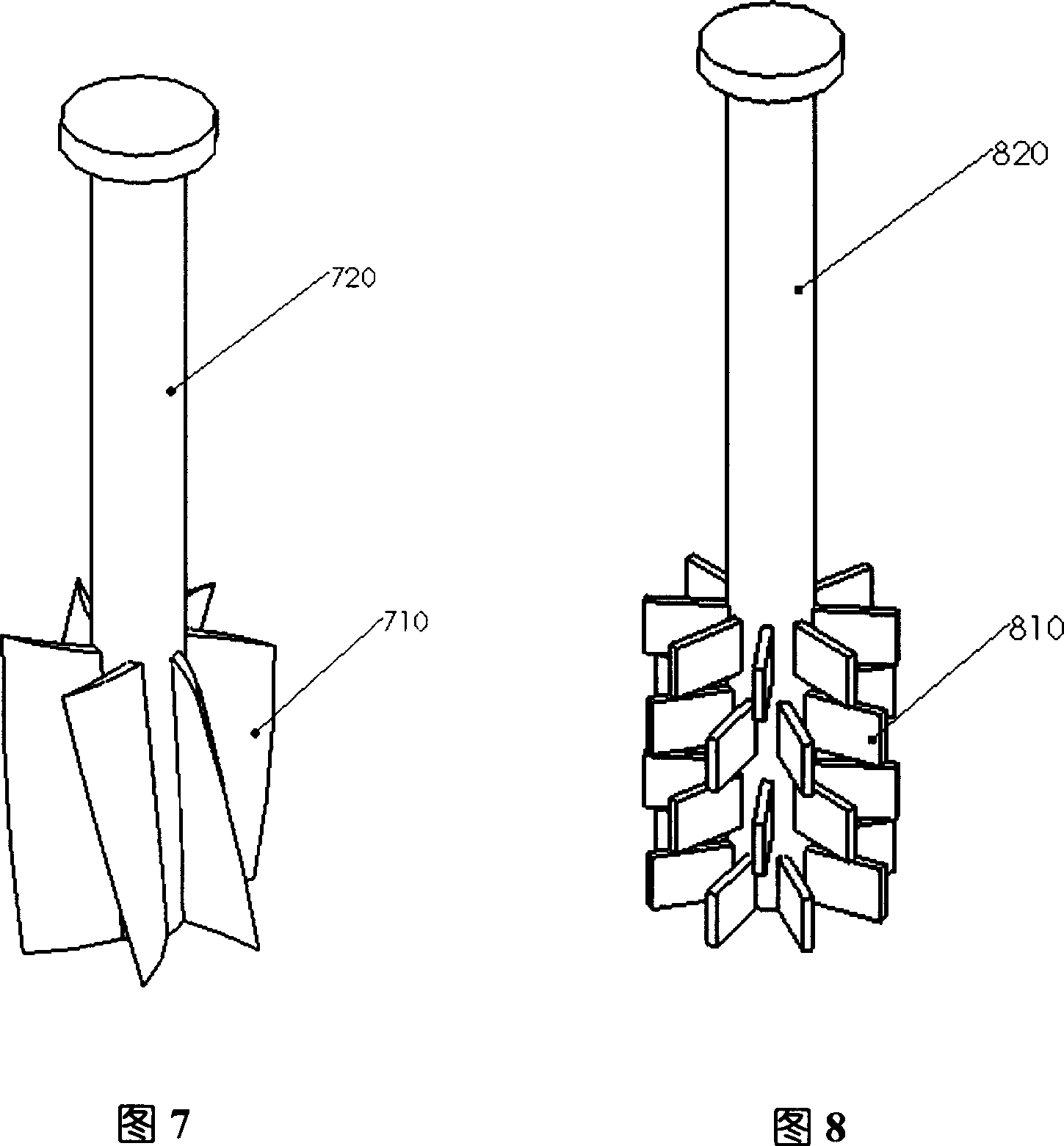

Embodiment 3

[0049] As shown in Figures 5 and 7, in the third embodiment of the present invention, the stirring tank is the same as the stirring tank of the prior art, the blades of the agitator are in multiple groups, and the blades and the central axis of the agitator have a certain angle α.

[0050] Introduce the alkali-free molten glass in the patent CN200510007338.0 into the feeding system shown in the present invention. The stirring tank and the agitator in the feeding system in the present example are the stirring tank and the agitator shown in Figure 5 and Figure 7 respectively; In the agitator shown in Figure 7, there are 6 blades, the outer diameter of the blades is 220mm, the diameter of the central shaft is 70mm, the rotation angle of the blades is 15°, and the diameter of the pipe connecting the mixing tank and the material bowl is D c =150mm, length L along the cooling pipe c =2000mm, equivalent diameter of stirring tank D st =250mm, the height L of the glass liquid in the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com