Microwave heating feeding passage and glass products manufacturing method using the feeding passage

A technology of microwave heating and glass products, applied in glass manufacturing equipment, feeding troughs, feeding nozzles, etc., can solve problems such as difficulty in controlling the temperature of glass liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

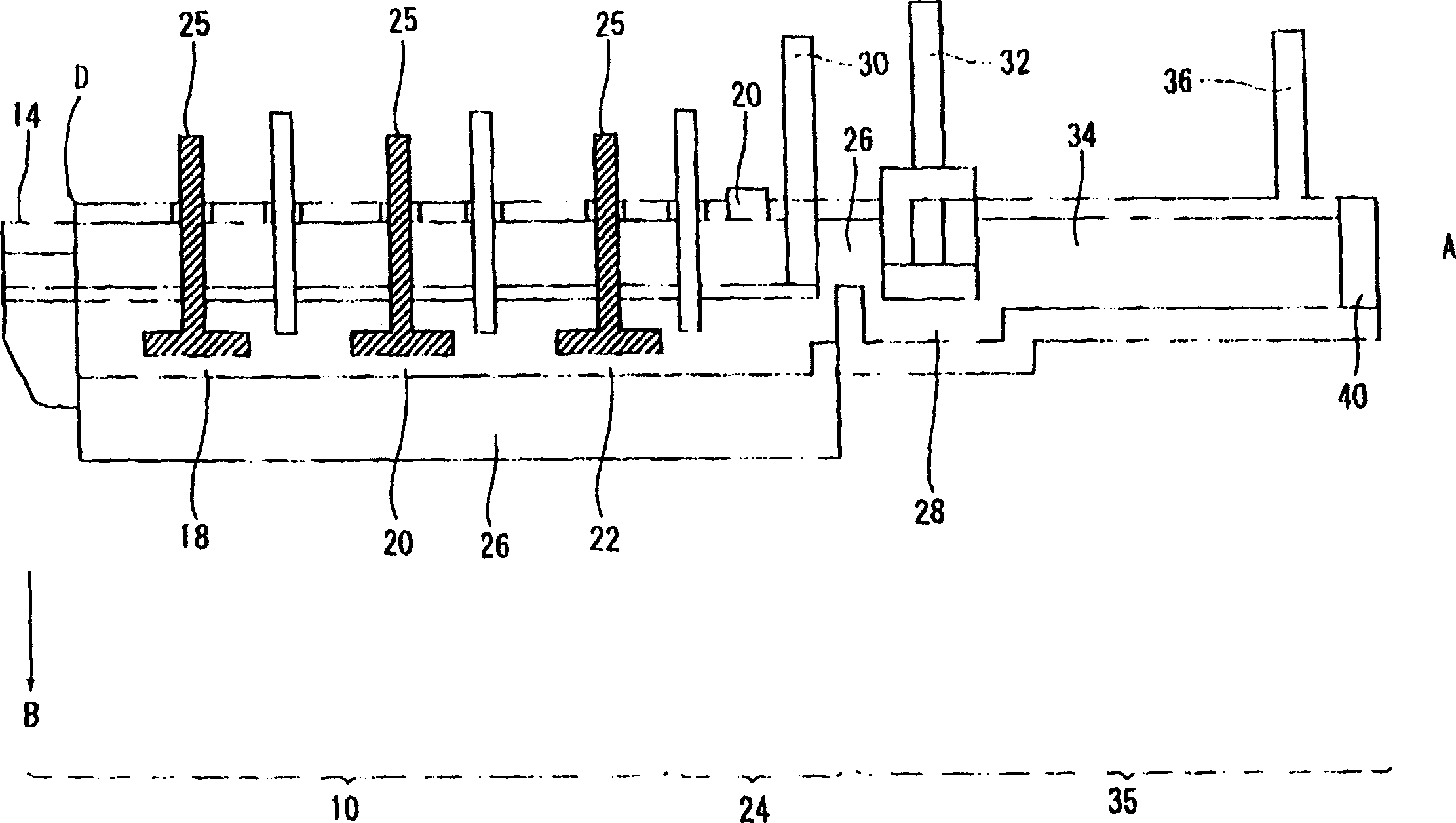

[0042] The first embodiment refers to microwave heating forehearth. A microwave generator is installed on the forehearth for transferring molten glass. A high-frequency power supply inputs high-frequency waves to generate microwaves through resonator vibration. The microwaves are used to heat the molten glass.

[0043] 1. Feed channel

[0044] style

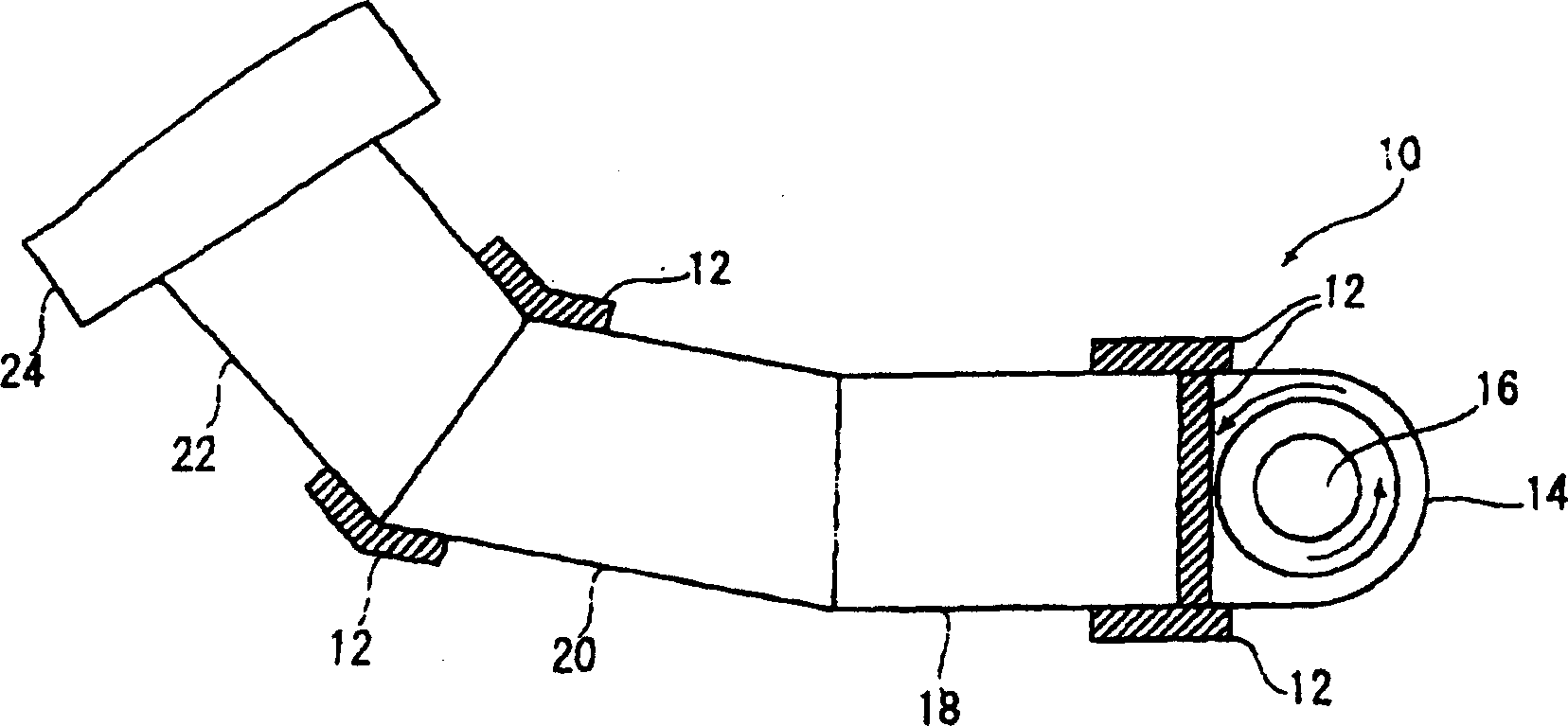

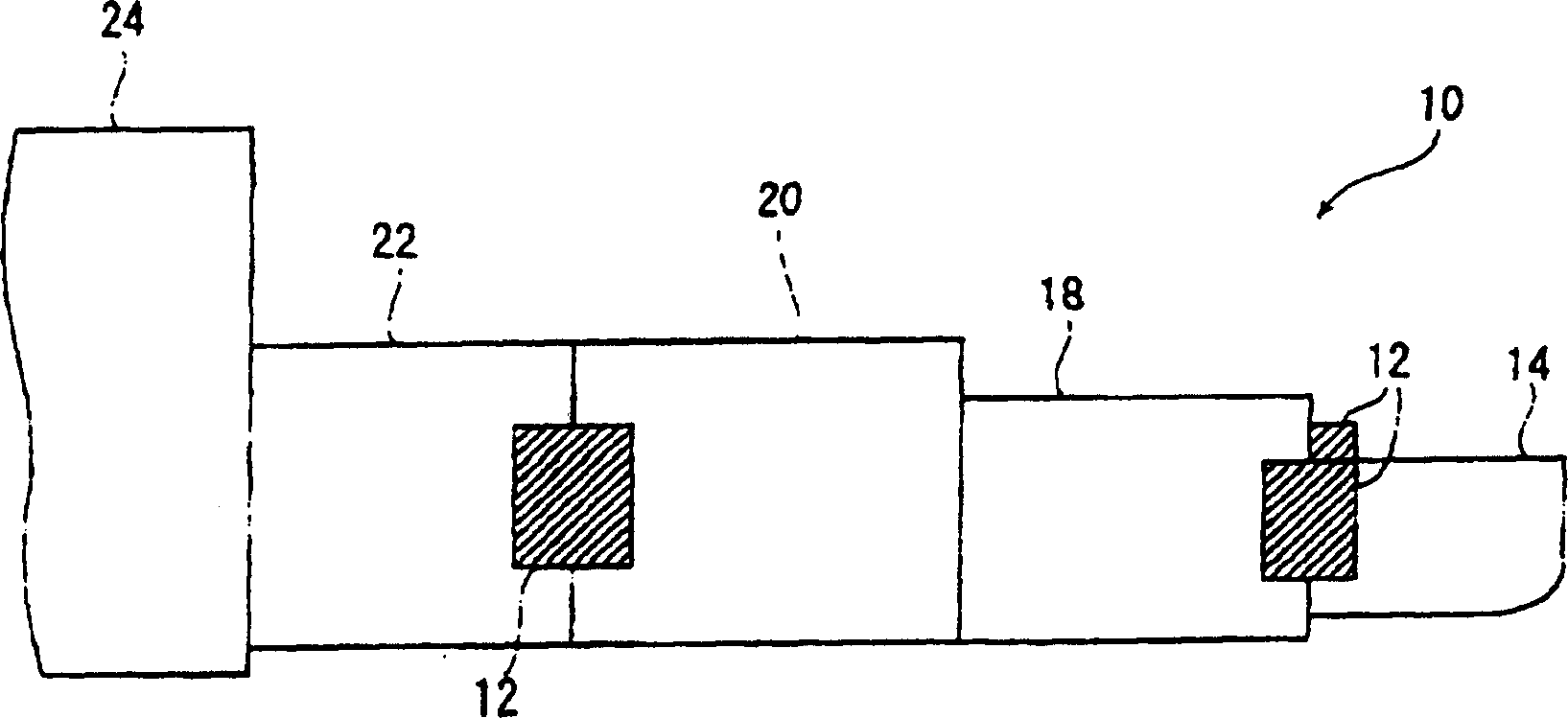

[0045] The style of the feed channel is not particularly limited. For example, as shown in Figure 1 (A) and (B), it is a channel for transferring molten glass. One end communicates with the clarification chamber 24, and the other end is equipped with a feed basin 14. The middle is a temperature adjustment Areas 18, 20, 22.

[0046] Considering the position of the glass forming machine, the temperature adjustment area 20 and 22 of the supply channel can be designed to be arranged with a certain curvature, but the curvature is the cause of the uneven temperature of the glass liquid in the supply channel, so the curvature It canno...

no. 2 Embodiment

[0108] The second embodiment refers to a method for producing glass products by heating the forehearth with microwaves. It includes three processes of melting process, heating process and forming process.

[0109] 1. Melting process

[0110] The melting process refers to the process of melting glass raw materials at a specified temperature in a melting furnace. Generally, the glass raw material is heated at a high temperature of 1400~1600℃ to melt it into molten glass, and the viscosity of the molten glass is in the range of 100~50,000pa.s.

[0111]The type of glass can be soda-lime glass, borosilicate glass, lead glass, lead-silicate glass, phosphate glass and so on. Glass composition may contain: SiO 2 、Al 2 o 3 , B 2 o 3 、Na 2 O, K 2 O, CaO, PbO, etc.

[0112] The glass color can be colorless and transparent, tinted transparent, tinted translucent, and the like.

[0113] In addition, in order to increase the effect of microwave heating, 0.01-10% by weight of nick...

example 1

[0134] 1. Production of glass products

[0135] SiO 2 、Na 2 O, K 2 O, CaO, MgO and Al 2 o 3 These soda-lime glass raw materials are put into a melting furnace and heated at a high temperature of 1500°C to melt them. The viscosity of the soda-lime glass liquid is 10,000pa.s.

[0136] The molten glass then enters the clarification chamber from the melting chamber, and then enters the supply channel, on which a microwave generating device is installed. The length of the feeding channel is about 8m, and the microwave generator is installed at the junction of the feeding basin and the feeding channel. The flow rate of the glass liquid is about 35mm / min, the frequency of the microwave is 2.45GHZ, and the power consumption is 4KW. The microwave is used to heat the glass. At the same time as the liquid is being poured, several flame injection devices on both sides of the supply channel also spray flames to heat the molten glass.

[0137] Cut the molten glass flowing out of the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com