Glass bottle feeding machine control system and control method

A technology of control system and feeding machine, which is applied in the direction of program control in feeding machine nozzle, glass manufacturing equipment, sequence/logic controller, etc. Flexible and convenient, ensure cutting accuracy, and work stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

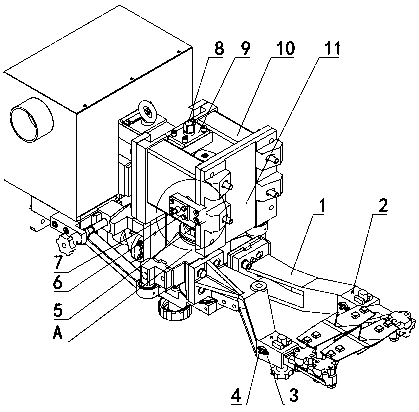

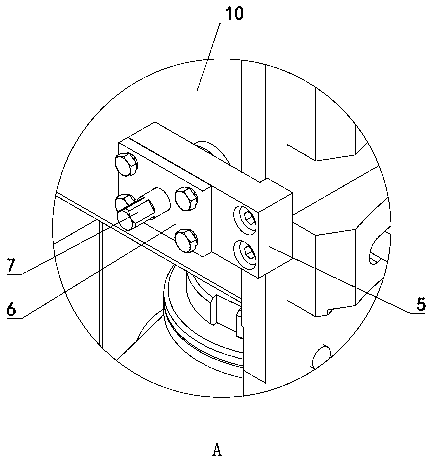

[0061] Figure 1~10 It is the best embodiment of the present invention, below in conjunction with the attached Figure 1~10 The present invention will be further described.

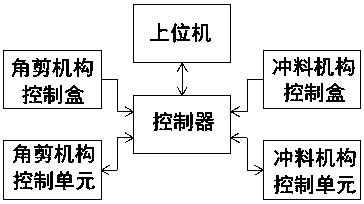

[0062] Such as figure 1 As shown, the control system of the glass bottle feeder includes a host computer, a controller, a control box for the angle shear mechanism, a control unit for the angle shear mechanism, a control box for the punching mechanism, and a control unit for the punching mechanism. The controller is realized by a conventional PLC. The upper computer is bidirectionally connected with the controller, the angle shear mechanism control box and the punching mechanism control box are connected to the input port of the controller, and the angle shear mechanism control box is provided with a number of buttons for controlling the angle shear mechanism; the punching mechanism control box There are several keys for controlling the punching mechanism in the middle. The controller is bidirectionall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com