Optical glass edge drop material forming device and forming method

A technology of optical glass and forming device, which is applied in the direction of the feeding machine nozzle, etc., can solve the problems of poor optical uniformity of glass, forming streaks, crystallization cannot be effectively controlled, and limited specifications and sizes, so as to improve optical uniformity and stress and control The effect of forming stripes technical difficulties, easy loading and unloading and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the drawings.

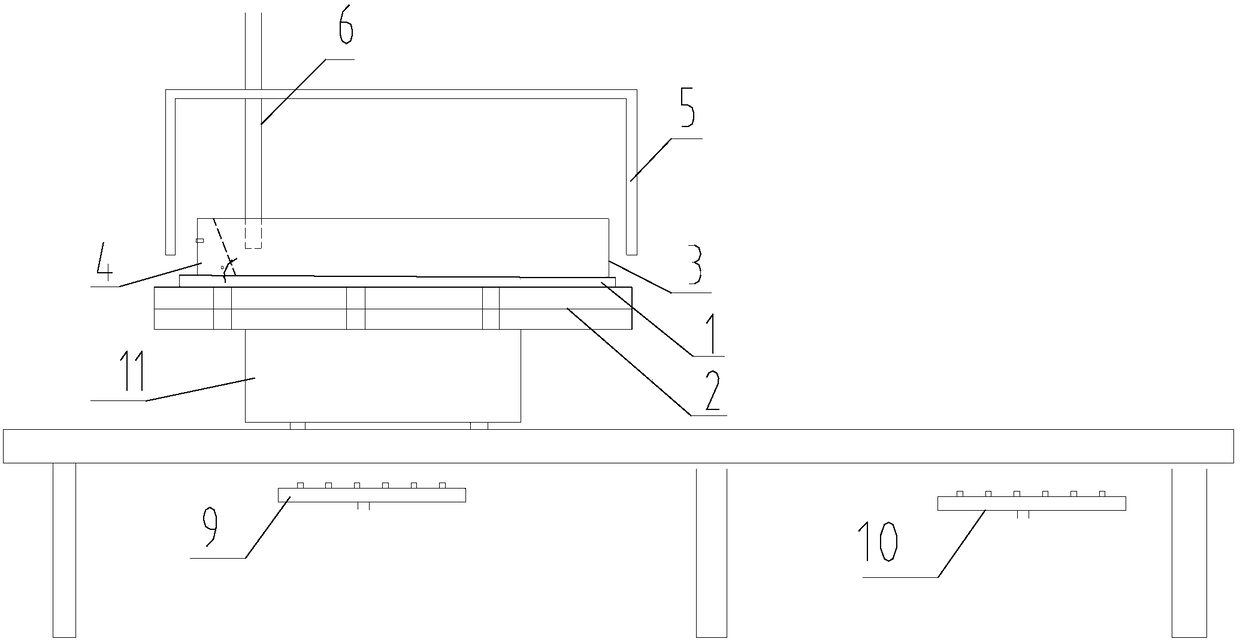

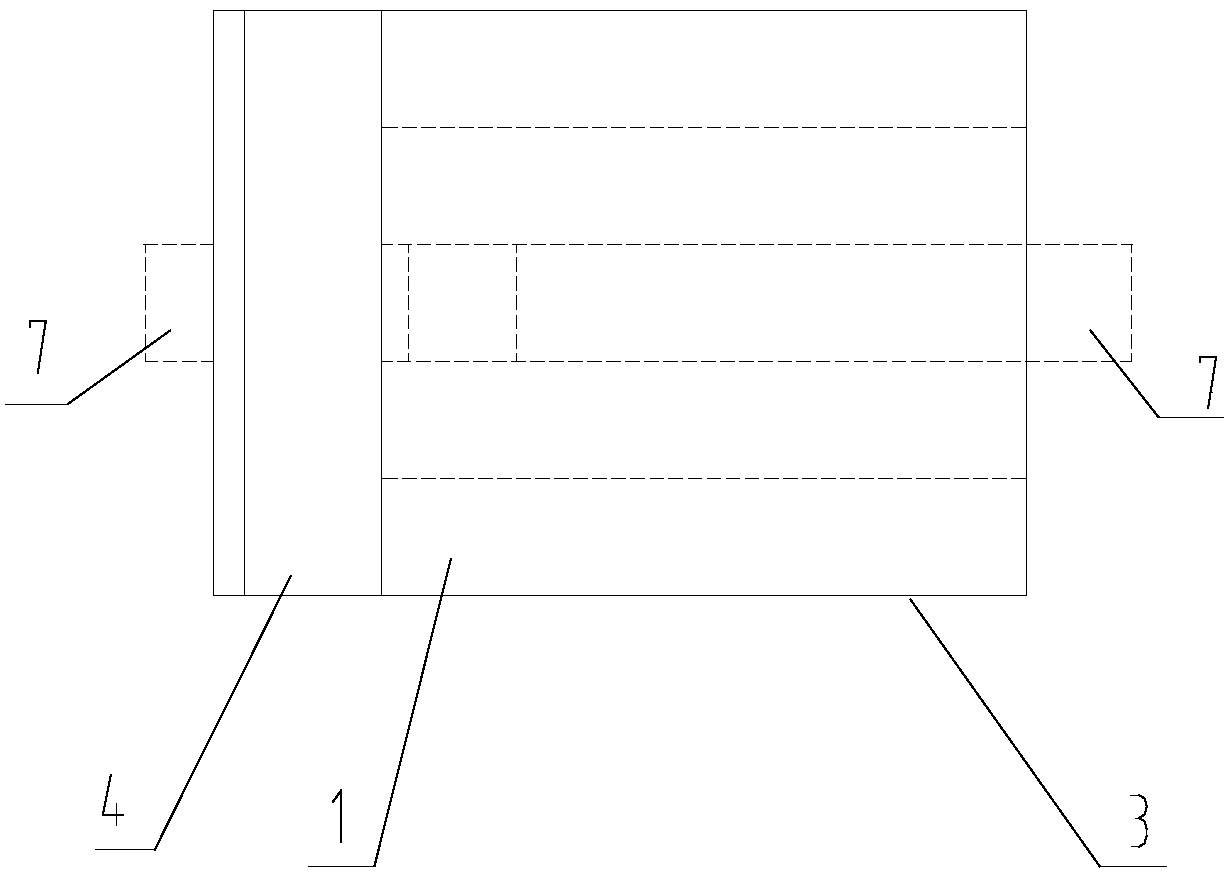

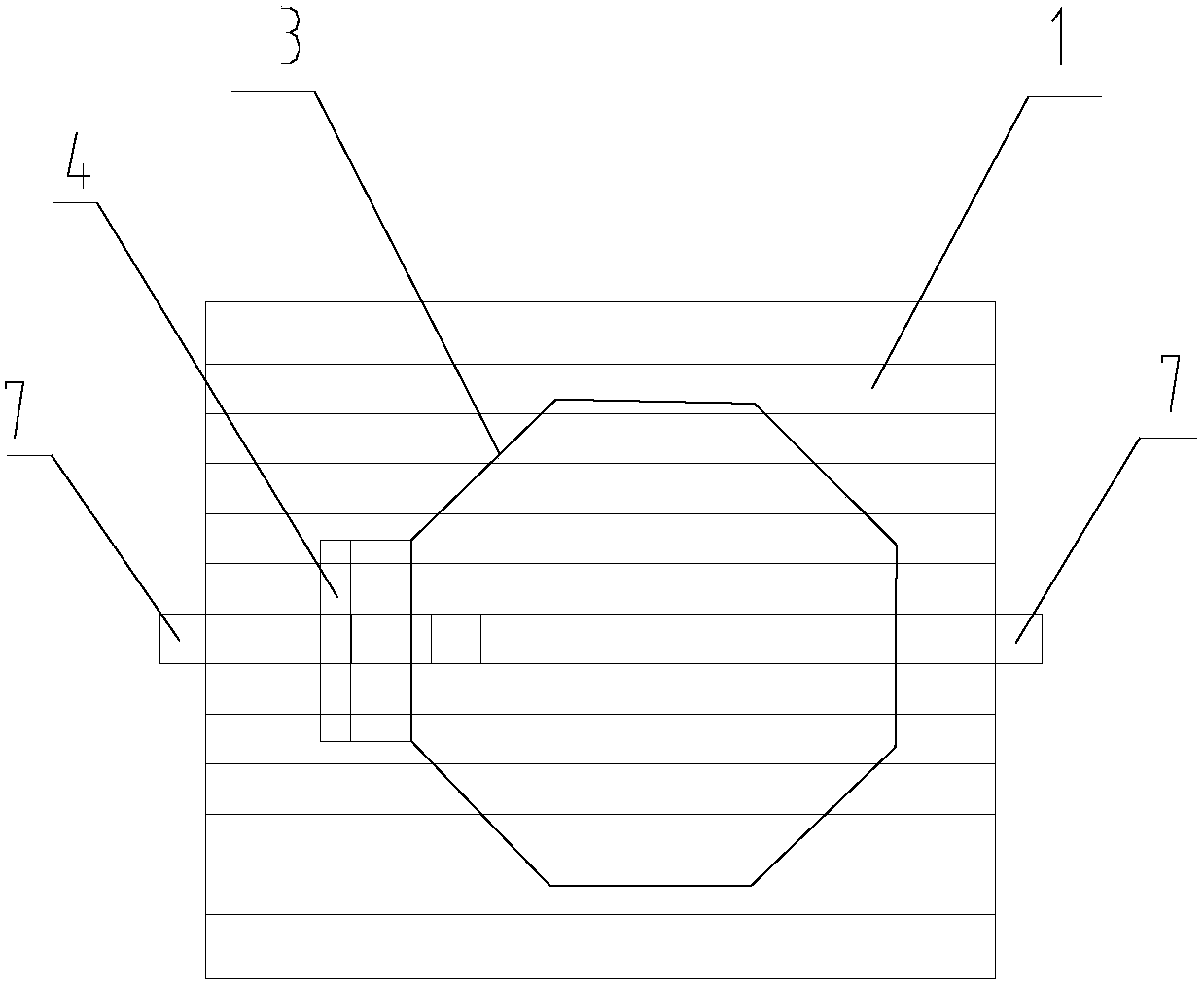

[0022] Such as figure 1 As shown, the large-diameter optical glass drop molding device of the present invention includes a bottom mold 1, a frame 3, a plug 4, a movable pull plate 7, a bracket 2, a rail car 11, a heating system, and a preheating system. The frame 3 and the plug 4 are arranged on the bottom mold 1, and the frame 3 is arranged around the bottom mold 1, the plug 4 is arranged inside the frame 3, and a vertical surface of the plug 4 is in contact with one side of the frame 3, and Use screws to fix. Since the frame 3 has only side surfaces and no bottom surface, the bottom mold 1, the frame 3, and the plug 4 constitute a molding die for optical glass, and the bottom mold 1 and the frame 3 can also be made into an integrated structure. The bottom mold 1 is provided with two embedded movable pull plates 7, and the two pull plates 7 can be pulled out or inserted. When pulled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com