Apparatus and method for processing molten glass

A technology for molten glass and equipment, applied in the field of molten glass processing, can solve the problems of molybdenum or tungsten core oxidation, plunger failure, complex layers, etc., to achieve the effects of low production cost, increased fracture resistance, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

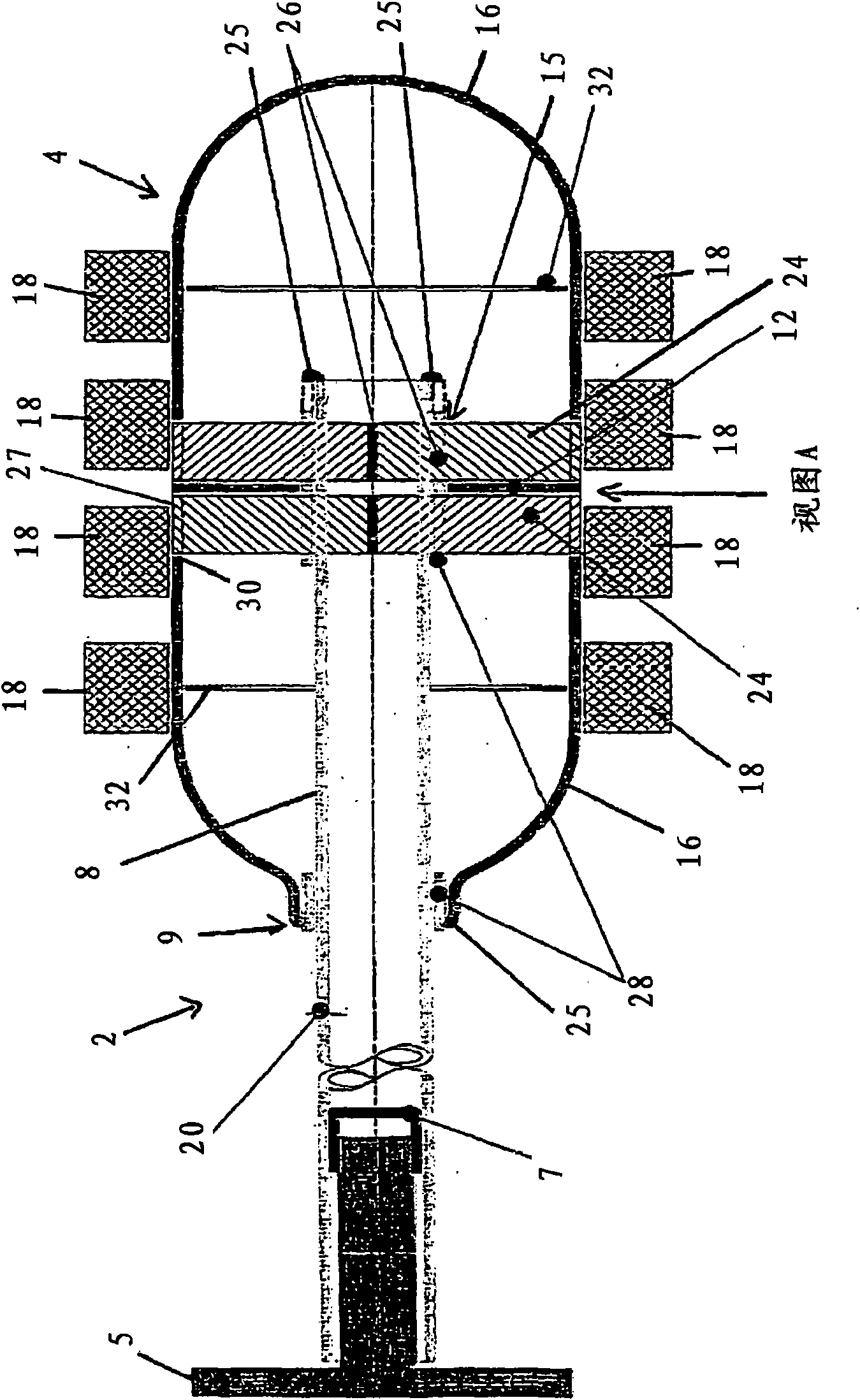

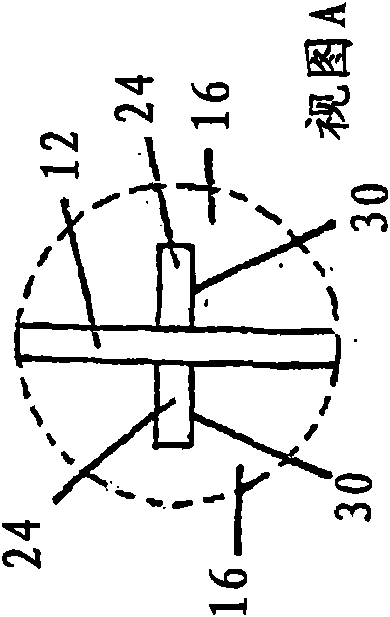

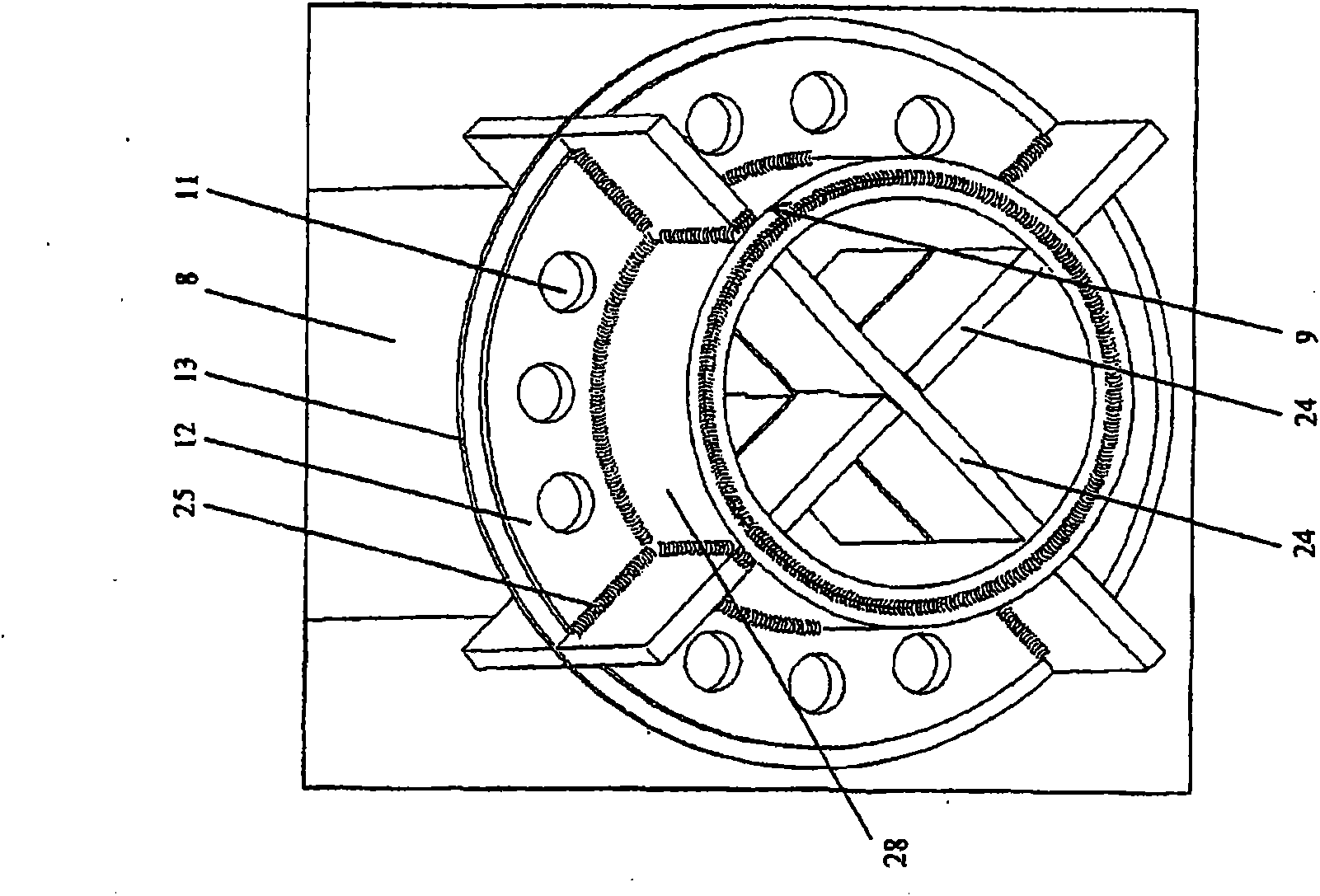

[0063] Figure 1a A longitudinal section through a first embodiment of a device 2 according to the invention is shown. The device 2 is designed in this case as, for example, a stirrer and has a rod 20 and an actuating device 4 which are moved via a drive (not shown). For this purpose, a driver or holding flange 5 is provided on the rod 20 . The driver or holding flange 5 is in this case received in a rod 20 and is provided with a protective cap 7 preferably consisting of a PGM material including, for example, an oxide dispersion strengthened PGM material.

[0064] The rod 20 of the device 2 according to the invention has at least one at least partially or completely seamless tube, which preferably consists of an oxide dispersion strengthened PGM material or at least comprises such a material. The rod 20 has a first thickened portion 9 to which the actuating means 4 is fastened, preferably by means of welding. The welding can in this case create a stable and glass-tight fast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| torque | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com