Apparatus for use in direct resistance heating of platinum-containing vessels

A container and electrode technology, applied in the field of direct resistance heating of platinum-containing containers, can solve problems such as material failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In the following detailed description, for purposes of illustration and not limitation, example embodiments are set forth in numerous specific details in order to provide a thorough understanding of the present invention. However, it will be apparent to those of ordinary skill in the art, having reference to the disclosure herein, that the invention may be practiced in other embodiments without departing from the specific details disclosed herein. Moreover, descriptions of well-known devices, methods and materials are omitted so as not to obscure the description of the present invention. Finally, as far as possible, the same components are designated with the same reference numerals.

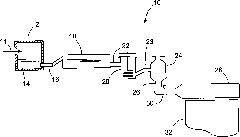

[0037] exist figure 1 In the exemplary apparatus 10, batch materials indicated by arrows 11 are melted in a furnace or melter 12 to form molten glass 14 at a first temperature T1. T1 depends on the specific glass composition, but for glass capable of being used as an LCD, T1 can exceed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com