Passivation of laser faceting and system for performing passivation of laser faceting

A facet and passivation layer technology, which is applied in the passivation field of laser facets, can solve the problems of shortening the life of the laser and increasing the cost, and achieve the effect of less optical loss, lower reliability and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

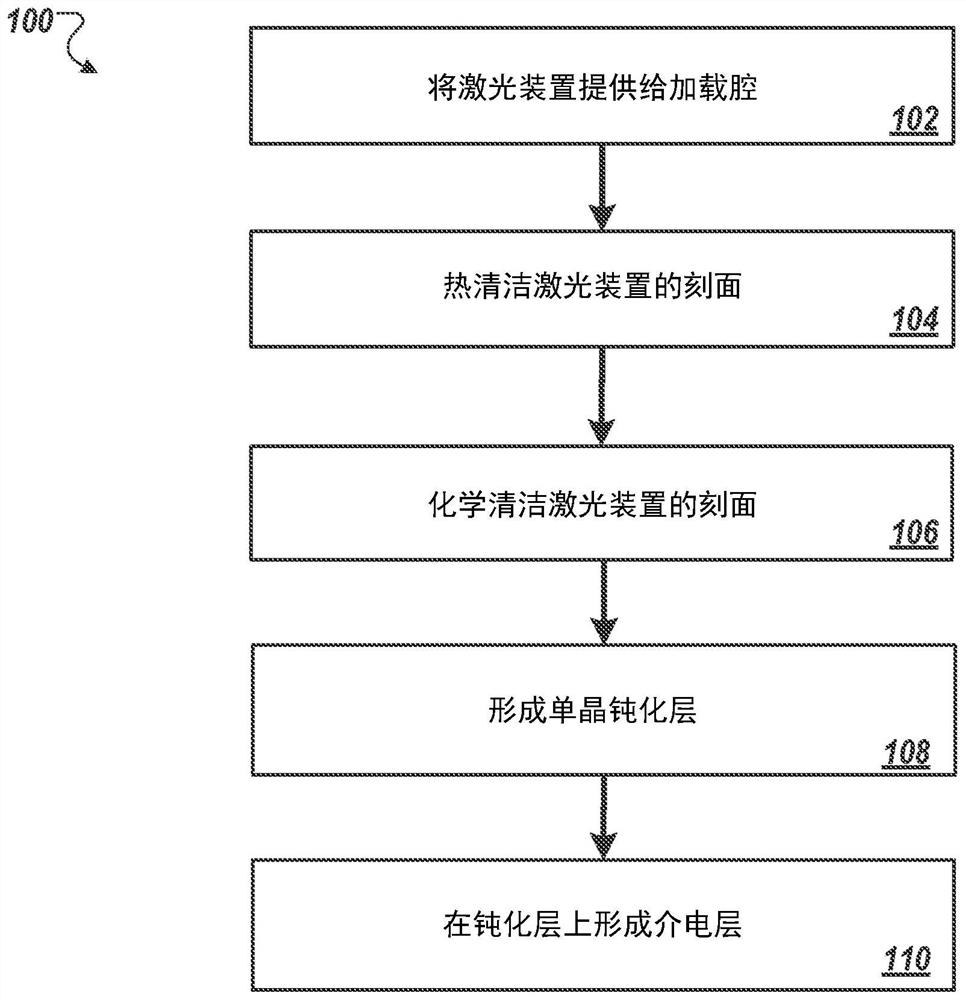

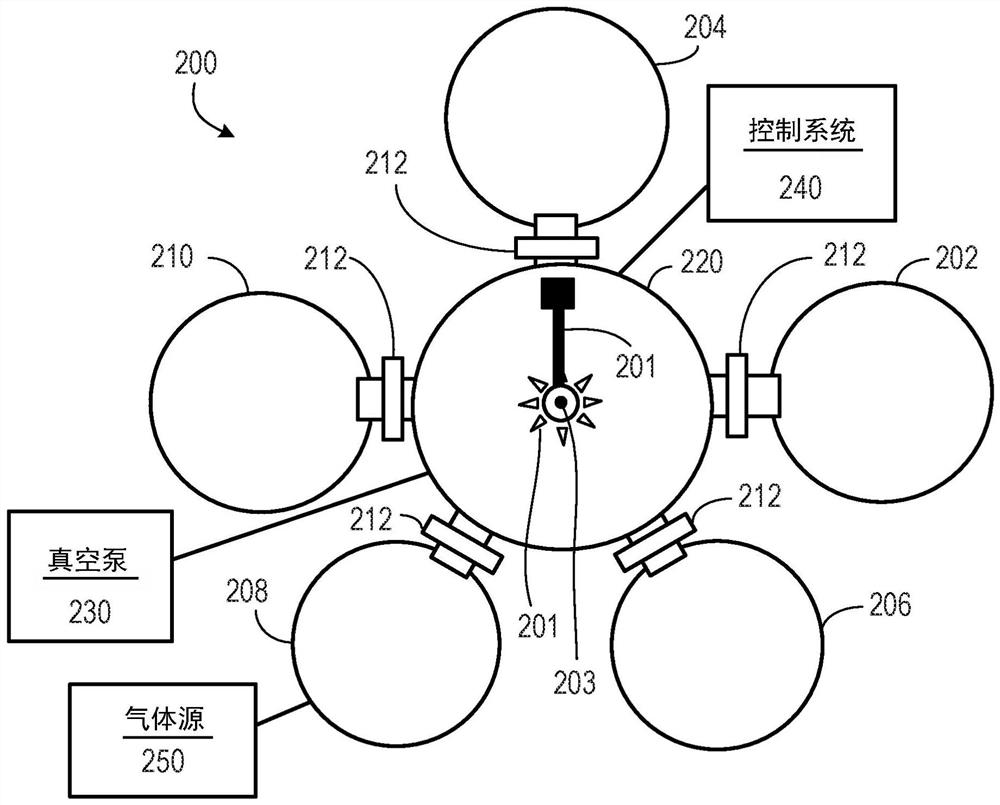

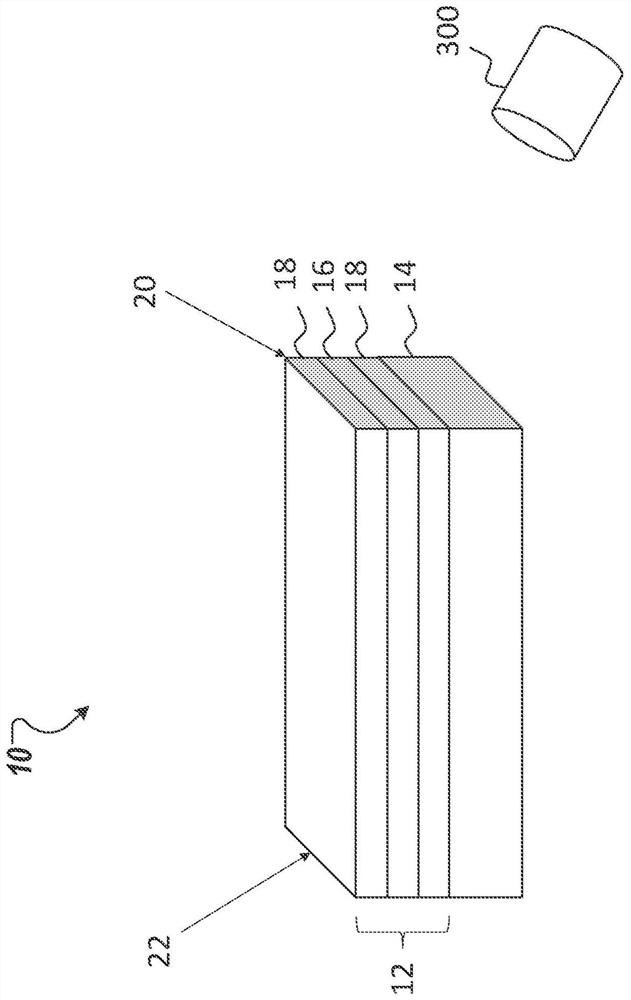

[0035] figure 1 An example of a process 100 for fabricating a high quality semiconductor laser facet passivation layer is shown. figure 2 An integrated multi-chamber ultra-high vacuum (UHV) system 200 is shown in which process 100 may be performed. Figure 3-6 Different states of the laser device 10 that have been enhanced to passivate the process 100 are shown.

[0036] Such as figure 2 As shown, the integrated multi-chamber UHV system 200 includes a central chamber 220 and a plurality of secondary chambers ( 202 , 204 , 206 , 208 , 210 ), each coupled to the central chamber through a corresponding gate valve 212 . The gate valve includes a passage through which objects can move and which can be sealed to maintain a vacuum. Gate valve 212 may be configured for use in a UHV environment and to isolate the secondary chamber from central chamber 220 . The plurality of secondary chambers includes, for example, a degassing chamber 202, a device inversion chamber 204, an atomi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com