Preparation method of dihydric alcohol titanium

A technology of titanium diol and diol, applied in the field of preparation of titanium diol, can solve the problems of high anhydrous degree, difficult operation and high equipment requirements, achieve less harsh reaction conditions, simplify technological process, The effect of reducing process energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

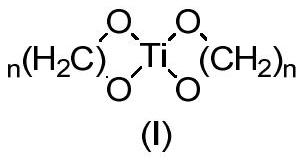

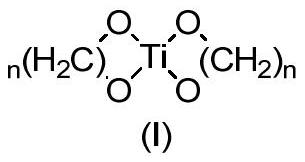

Image

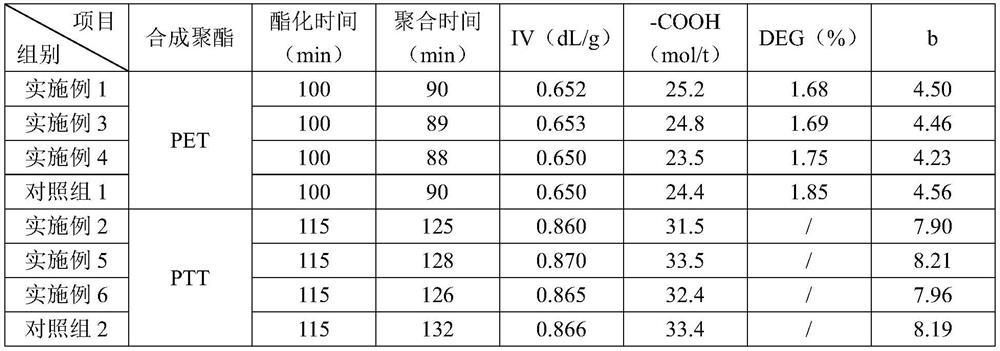

Examples

Embodiment 1

[0034] Add 19g (0.1mol) TiCl to the flask 4 , 112.5g (2.5mol) formamide, stir evenly, dropwise add 12.4g (0.2mol) ethylene glycol at room temperature, control the rate of addition, so that the reaction temperature does not exceed 50 ° C, and white solids are constantly formed during the reaction. After the dropwise addition, continue to stir the reaction until the raw material titanium tetrachloride remains less than 1%. After the reaction is finished, cool to normal temperature, filter and separate the white solid product, wash thoroughly with water whose temperature does not exceed 15°C until there is no chloride ion in the washing solution, then wash with acetone, and dry at 60°C to obtain the titanium ethylene glycol catalyst. The rate is 95.6%.

[0035] The titanium content in the ICP test catalyst is 28.49%.

Embodiment 2

[0037] Add 19g (0.1mol) TiCl to the flask 4 , 135g (3mol) formamide, stir evenly, add 15.2g (0.2mol) 1,3-propanediol dropwise at room temperature, control the rate of addition, so that the reaction temperature does not exceed 60 ° C, white solids are constantly formed during the reaction, drop After the addition is complete, continue to stir the reaction until the raw material titanium tetrachloride remains less than 1%. After the reaction, cool to normal temperature, filter to obtain a white solid, and wash the white product solid with a large amount of water (not exceeding 20° C.) until there is no chloride ion in the washing liquid. Then wash the white solid with acetone, and dry the white solid at no more than 60° C. to obtain titanium propylene glycol with a yield of 96.2%.

[0038] The titanium content in the ICP test catalyst is 24.50%.

Embodiment 3

[0040] Add 19g (0.1mol) TiCl to the flask 4 , a mixed solution of formamide-ethyl acetate containing 112.5g (2.5mol) of formamide (the volume ratio of formamide / ethyl acetate is 60:40), stir evenly, and add 12.4g (0.2mol) of ethylene glycol dropwise at room temperature , Control the rate of addition so that the reaction temperature does not exceed 50°C, and white solids are continuously generated during the reaction. After the dropwise addition, continue to stir the reaction until the raw material titanium tetrachloride remains less than 1%. After the reaction is finished, cool to normal temperature, filter and separate the white solid product, wash thoroughly with water whose temperature does not exceed 15°C until there is no chloride ion in the washing solution, then wash with acetone, and dry at 60°C to obtain the titanium ethylene glycol catalyst. The rate is 95.7%.

[0041] The titanium content in the ICP test catalyst is 28.52%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com