Polycarboxylate water reducer with modified sugar side chain structure and preparation method thereof

A technology of polycarboxylic acid and water-reducing agent, applied in the field of concrete admixtures, can solve the problems of difficulty in guaranteeing concrete quality, low water retention and tackifying effect, influence on concrete strength, etc., and achieves excellent stability performance, small change in fluidity, early high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

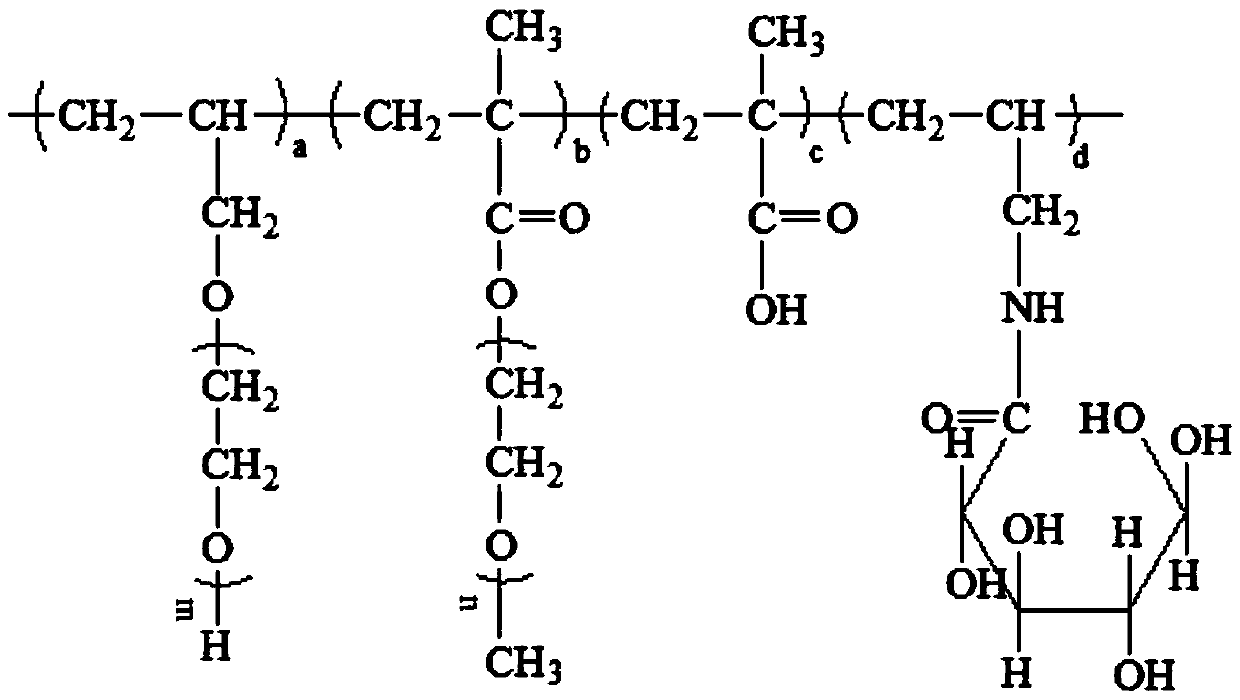

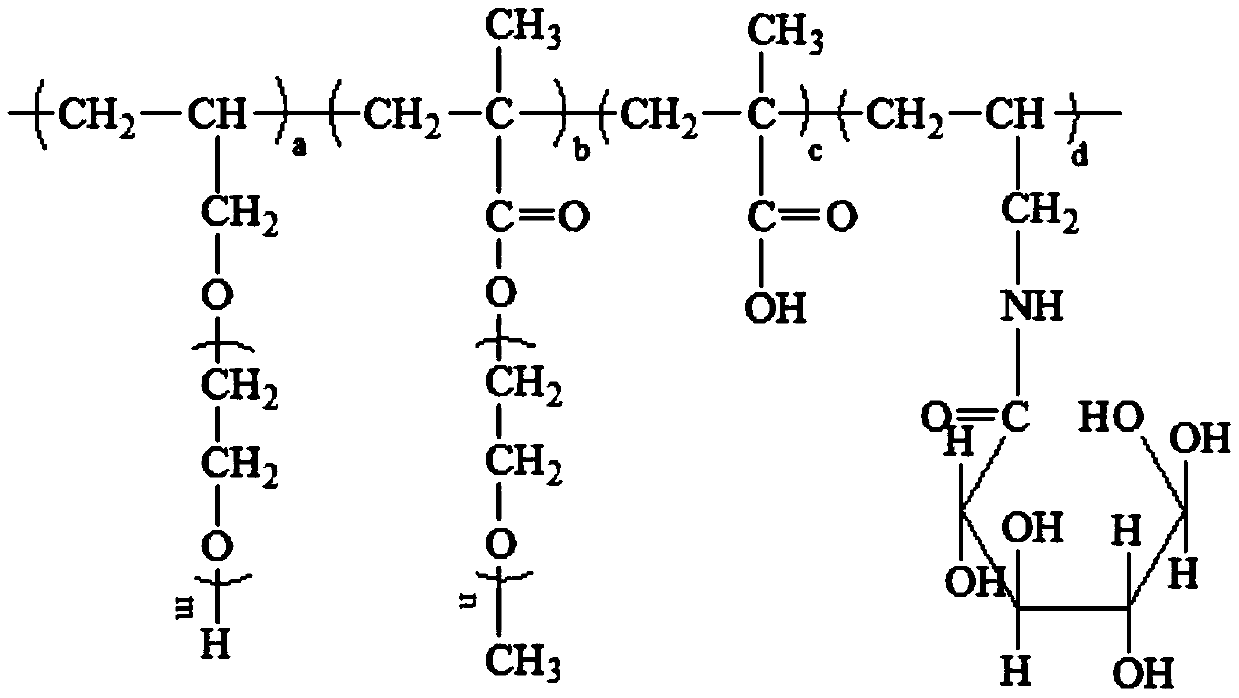

Method used

Image

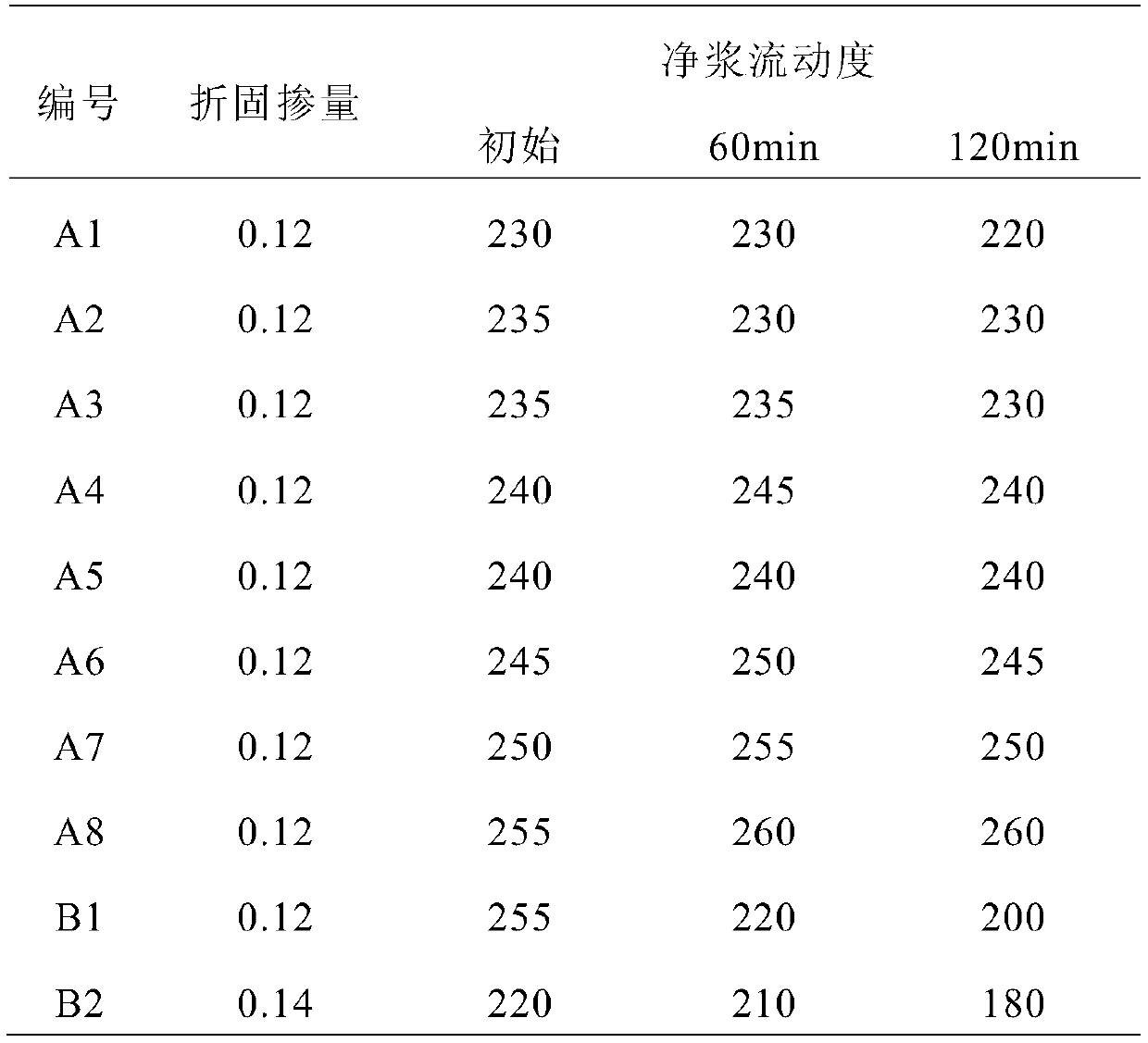

Examples

preparation example Construction

[0026] The preparation method of a polycarboxylic acid water reducing agent with modified sugar side chain structure of the present invention includes the following steps:

[0027] 1) Add allyl polyethylene glycol, polyethylene glycol monomethyl ether methacrylate and deionized water into the reaction kettle, and heat and dissolve at a temperature of 20 to 80°C to obtain a solution A;

[0028] 2) Add the deionized aqueous solution of ammonium persulfate and the deionized water mixed solution of methacrylic acid and glucose allyl amide monomers to the A solution at the same time, and carry out the heat preservation reaction at the temperature of 60~80℃ 1.0~2.0 h and cool to room temperature to obtain B solution;

[0029] 3) Add 30% mass fraction of liquid caustic soda to the B solution, adjust the pH to 6-8, and obtain 40% mass fraction of polycarboxylic acid water reducing agent with modified sugar side chain structure; allyl polyethylene glycol , The molar ratio of methacrylic acid...

Embodiment 1

[0031] (1) Synthesis of glucose allyl amide monomer: use DMF as solvent, add allyl amine into the reaction kettle, heat to completely dissolve, and then add D-gluconate-δ-lactone to the reaction kettle. React at ℃ for 2h, remove DMF solvent in vacuum, wash with epoxy hexane, filter, recrystallize twice in isopropanol, and dry in vacuum to obtain white powdery glucose allyl amide monomer, D-gluconic acid -The molar ratio of δ-lactone to allylamine is 1:1;

[0032] (2) Polymerization reaction: add allyl polyethylene glycol with a molecular weight of 2000, polyethylene glycol monomethyl ether methacrylate with a molecular weight of 400, and deionized water into the reaction kettle, at a temperature of 20 to 80 ℃ After heating and dissolving, a solution A is obtained; in solution A, the deionized water solution of ammonium persulfate and the deionized water mixed solution of methacrylic acid and glucose allyl amide monomer are added dropwise at the same time, and the mixture is added...

Embodiment 2

[0034] (1) Synthesis of glucose allyl amide monomer: same as Example 1;

[0035] (2) Polymerization reaction: Add allyl polyethylene glycol with a molecular weight of 2400, polyethylene glycol monomethyl ether methacrylate with a molecular weight of 550 and deionized water into the reaction kettle at a temperature of 20 to 80°C After heating and dissolving, A solution is obtained; In solution A, the deionized aqueous solution of ammonium persulfate and the deionized water mixed solution of methacrylic acid and glucose allyl amide monomer are added dropwise at the same time, and the mixture is added dropwise at 80℃ for 3.0h After the dripping is completed, the reaction is kept at 70℃ for 1.5h. After the reaction, it is cooled to room temperature to obtain B solution; then 30% mass fraction of liquid caustic soda is added to B solution, and the pH value is adjusted to 6-8 to obtain the product. It is a polycarboxylic acid water reducing agent with a modified sugar side chain struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com