Alkyd resin modified by low-chain active resin, preparation method and self-drying paint

A technology of active resin and alkyd resin, applied in the field of self-drying paint, can solve the problems of high content, cannot reduce organic solvent pollution, low viscosity, etc., and achieve the effects of good system stability, good fullness and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

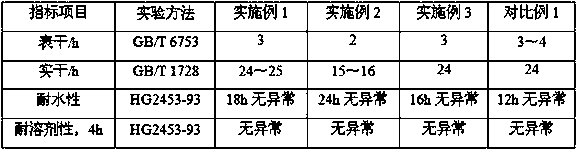

[0046] A low-chain active resin-modified alkyd resin Example 1-3 Raw material components and proportioning ratio are shown in Table 1:

[0047] Table 1 A low-chain active resin modified alkyd resin Example 1-3 Raw material components and ratio table

[0048]

[0049] Note: "-" in the table means not added.

Embodiment 1

[0051] (1) Preparation method of component A: according to Table 1, put the raw materials in component A of Example 1 into the reactor by weight, and after sealing the reactor, start stirring at a speed of 100r / min, and heat up to After 180°C, heat-preserve and reflux for 1 hour, then continue to heat up to 240°C, heat-preserve and reflux for esterification for 4 hours, then start to detect the acid value, when the acid value is 12mgKOH / g, start to detect the viscosity, when the viscosity is 25s, cool down, Turn on the vacuum to extract the reflux solvent and set it aside;

[0052] (2) The preparation method of component B: according to Table 1, put the raw materials in the component B of Example 1 into the reactor by weight, and after sealing the reactor, start stirring at a speed of 100r / min, and heat up to After 160°C, keep warm and reflux for 1 hour, then continue to heat up to 190°C at a rate of 10°C / h, keep warm and reflux for esterification reaction for 4 hours, start t...

Embodiment 2

[0055] (1) Preparation method of component A: according to Table 1, put the raw materials in component A of Example 2 into the reactor by weight, and after sealing the reactor, start stirring at a speed of 100r / min, and heat up to After 180°C, keep warm and reflux for 1.5h, then continue to heat up to 235°C, keep warm and reflux for esterification reaction for 3h, start to detect the acid value, when the acid value is 10.0mgKOH / g, start to detect the viscosity, when the viscosity is 20s, Cool down, turn on the vacuum to extract the reflux solvent, and set aside;

[0056] (2) The preparation method of component B: according to Table 1, put the raw materials in the component B of Example 2 into the reactor by weight, and after sealing the reactor, start stirring at a speed of 90r / min, and heat up to After 170°C, keep warm and reflux for 1.5h, then continue to heat up to 210°C at a rate of 15°C / h, keep warm and reflux for esterification reaction for 3h, start to detect the acid v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com