Preparation and application of boron modified boron nitride catalyst for oxidative dehydrogenation of low-carbon alkane

A technology for oxidative dehydrogenation and low-carbon alkanes, which is applied in the direction of carbon compound catalysts, catalyst activation/preparation, physical/chemical process catalysts, etc. It can solve the problems of environmental damage, inability to realize industrial application, waste of raw materials, etc., and achieve good heat transfer performance, good thermal conductivity, and the effect of increasing the yield of olefins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

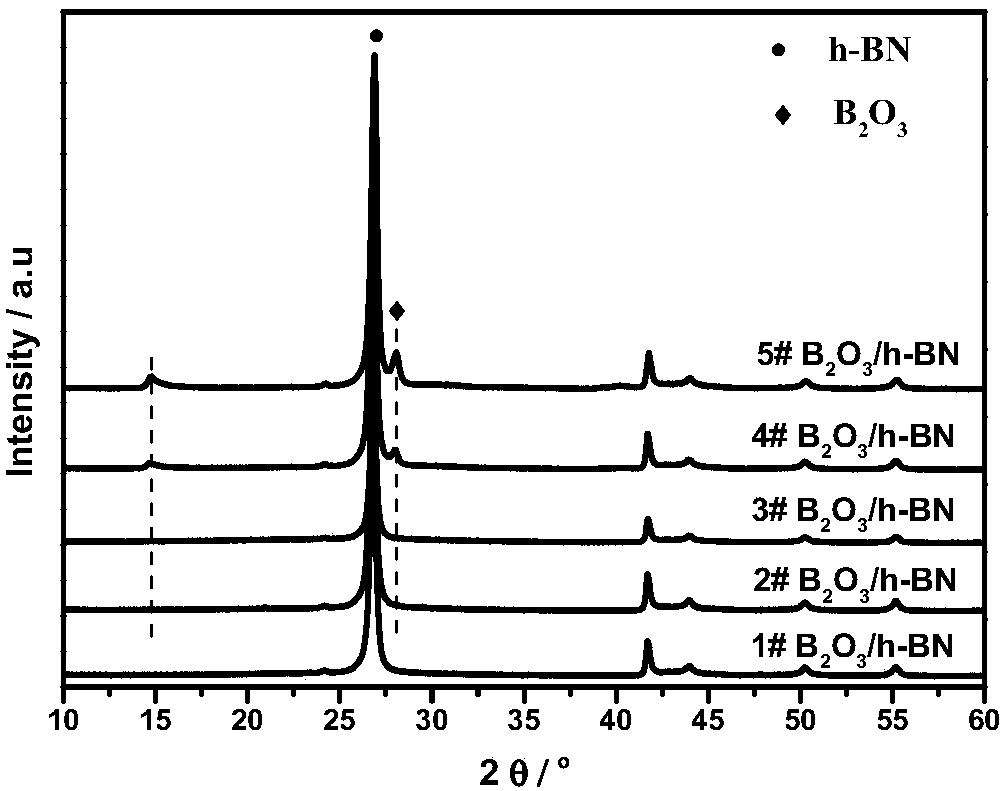

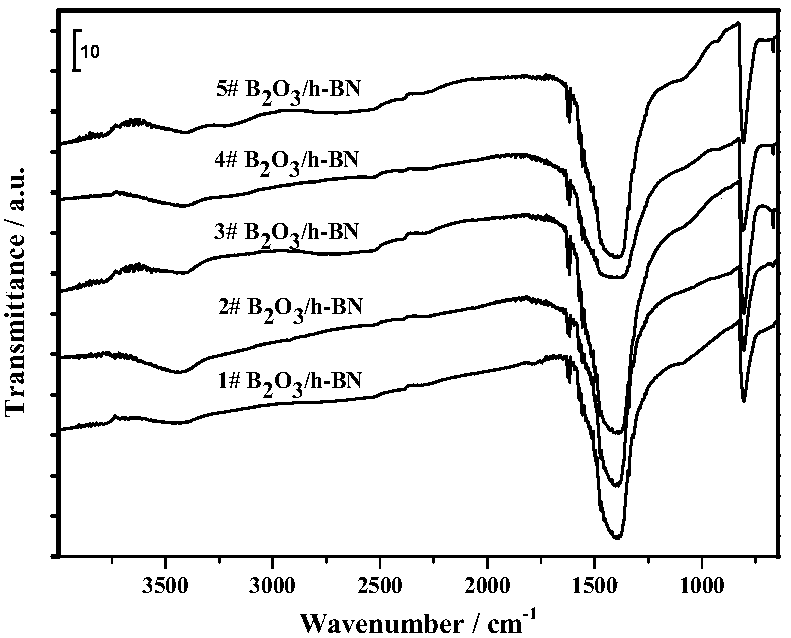

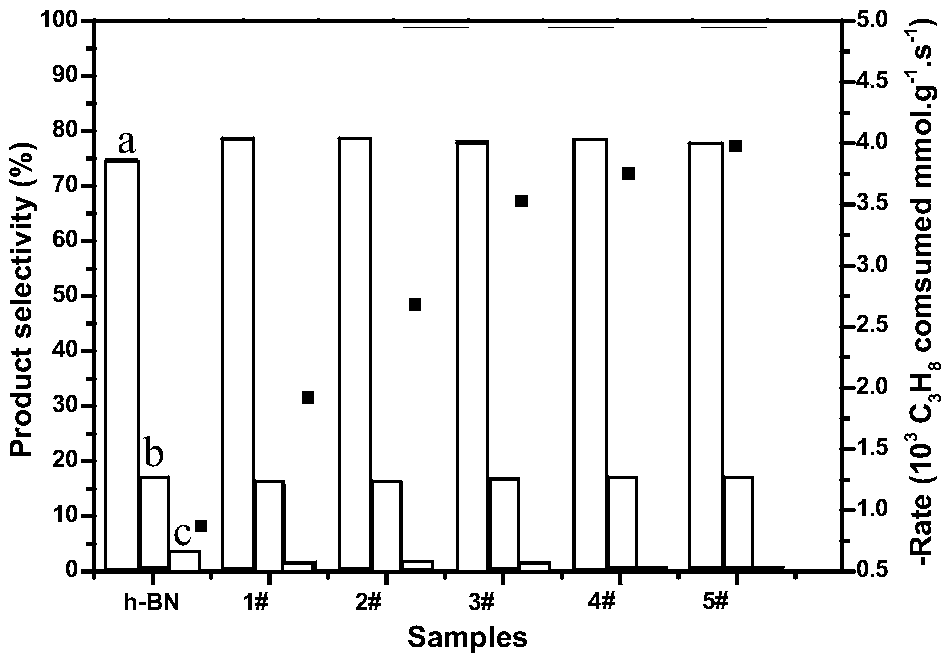

[0025] Embodiment 1 according to boron (with B 2 o 3 (calculated) was added in an amount of 1%, and 0.0023g of boron-containing precursor was weighed and dissolved in 10mL of water, and then 0.5g of boron nitride was added to it, soaked for a period of time at 60°C and then dried, and the solid was taken out and placed in quartz boat, and heat treatment at 600°C for 6h, the obtained material is B 2 o 3 / h-BN. Weigh the prepared B 2 o 3 The / h-BN catalyst (80-100 mesh) was packed in a fixed-bed reactor for evaluation of oxidative dehydrogenation of propane. Non-limiting changes to boron (in B 2 o 3 Calculation) addition amount and heat treatment temperature, the obtained boron modified boron nitride material is numbered as embodiment 1~embodiment 5 successively, such as figure 1 and 2 As shown, XRD and FT-IR spectrogram tests were carried out on different boron oxide loadings of the obtained boron-modified boron nitride catalyst, image 3 The effect of different boron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com