Preparation method of dehydrogenation catalyst

A dehydrogenation catalyst, alumina technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of active component Pt particle aggregation and growth, olefin selectivity reduction, catalyst deactivation and other problems , to achieve good dehydrogenation activity and selectivity, reduce olefin selectivity, and simplify the preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

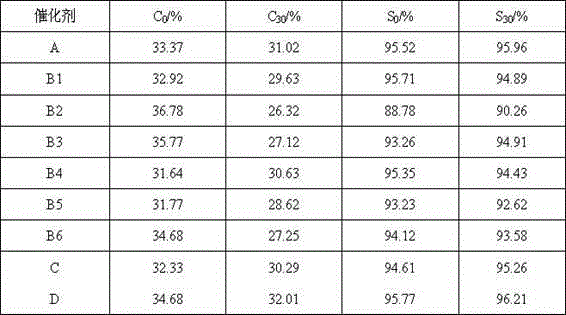

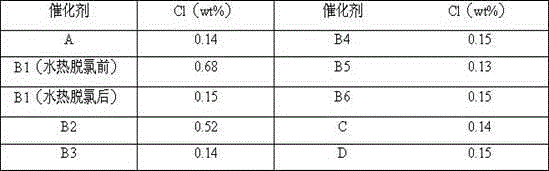

Embodiment 1

[0035] The preparation of the carrier: select 200 g of ZSM-5 molecular sieve with a relative crystallinity of 50% and a silicon-to-aluminum ratio of 100, mix it with 350 g of alumina, 25 g of sesame powder and 50 g of a 10% dilute nitric acid solution, and knead the bar. forming. The formed carrier was dried in the shade for 24 hours, then dried in an oven at 110°C for 12 hours, and then baked in a muffle furnace at 600°C for 6 hours. After cooling, it breaks into a length of 2-5mm and weighs 50ml of the carrier, impregnates and supports the catalytic component Sn, selects tin tetrachloride as the precursor, and is dried and roasted to obtain the Sn-containing carrier. Place it in a rotary evaporator and vacuum for 30 min.

[0036] Prepare the dipping solution: Weigh an appropriate amount of solid chloroplatinic acid and potassium nitrate, dissolve them in 100ml of deionized water, and stir thoroughly. Add nitric acid solution dropwise to adjust the pH value of the immersion li...

Embodiment 2

[0057] The preparation of the carrier: select 200 g of ZSM-5 molecular sieve with a relative crystallinity of 70% and a silicon-to-aluminum ratio of 100, and mix it with 400 g of alumina, 25 g of sesame powder and 50 g of a dilute nitric acid solution with a mass concentration of 10%. forming. The formed carrier was dried in the shade for 24 hours, then dried in an oven at 110°C for 10 hours, and then calcined in a muffle furnace at 600°C for 7 hours. After cooling, it breaks into a length of 2-5mm and weighs 50ml of the carrier, impregnates and supports the catalytic component Sn, selects tin tetrachloride as the precursor, and is dried and roasted to obtain the Sn-containing carrier. Place it in a rotary evaporator and vacuum for 30 min.

[0058] Prepare the dipping solution: Weigh an appropriate amount of solid chloroplatinic acid and potassium nitrate, dissolve them in 80ml of deionized water, and stir thoroughly. Add nitric acid solution dropwise to adjust the pH value of ...

Embodiment 3

[0063] The preparation of the carrier: select 200g of ZSM-5 molecular sieve with a relative crystallinity of 60% and a silicon-to-aluminum ratio of 150, mix it with 350g alumina, 25g sesame powder and 50g dilute nitric acid solution with a mass concentration of 10%. forming. The formed carrier was dried in the shade for 24 hours, then dried in an oven at 110°C for 10 hours, and then calcined in a muffle furnace at 600°C for 7 hours. After cooling, it breaks into a length of 2-5mm and weighs 50ml of the carrier, impregnates and supports the catalytic component Sn, selects tin tetrachloride as the precursor, and is dried and roasted to obtain the Sn-containing carrier. Place it in a rotary evaporator and vacuum for 60 minutes.

[0064] Prepare the dipping solution: Weigh an appropriate amount of solid chloroplatinic acid and potassium nitrate, dissolve them in 120ml of deionized water, and stir thoroughly. Add nitric acid solution dropwise to adjust the pH value of the immersion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com