Liquid acid alkylation reactor and alkylation reaction method

An alkylation reactor and alkylation reaction technology, applied in chemical methods for liquid-liquid reactions, chemical instruments and methods, chemical/physical/physicochemical fixed reactors, etc., can solve the problem of optimization space, etc. problems, to achieve the effect of compact structure, promoting alkylation reaction, and high alkene ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0069] This example is used to illustrate the liquid acid alkylation reactor of the present disclosure and the method for carrying out liquid acid alkylation using the reactor.

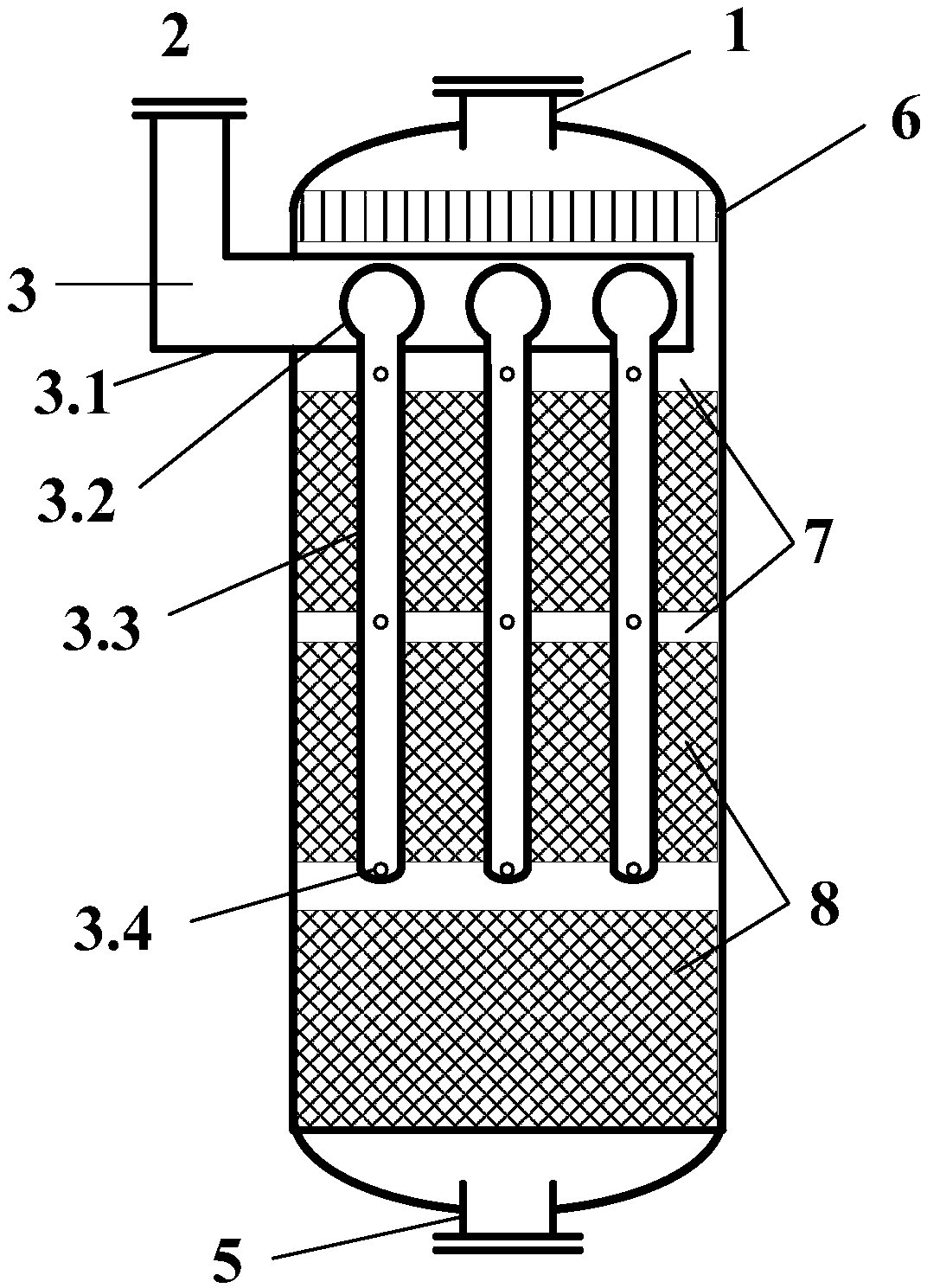

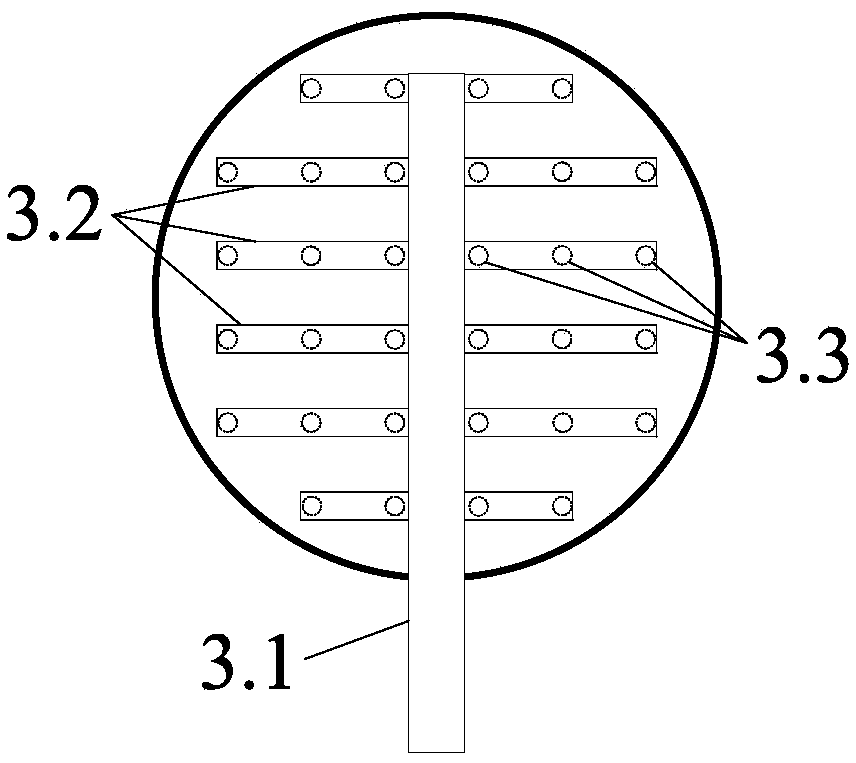

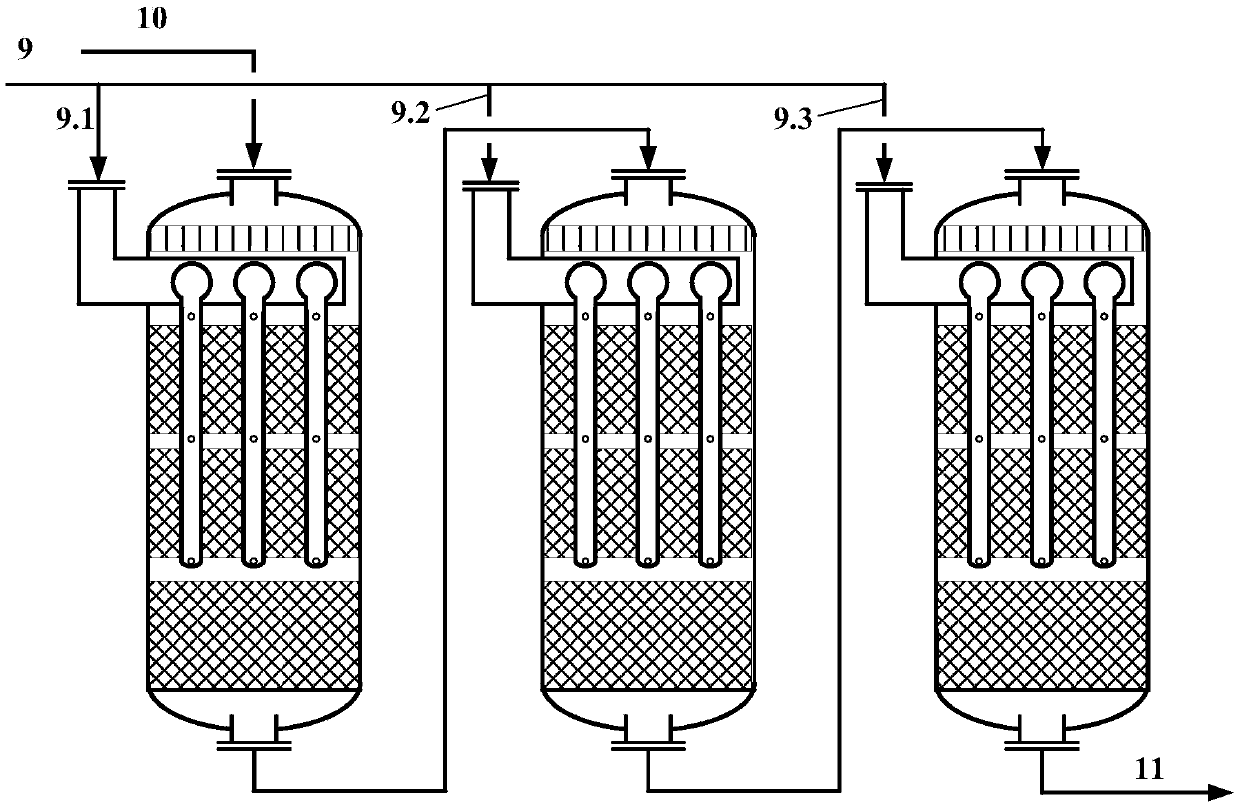

[0070] Such as figure 1 As shown, the liquid acid alkylation reactor includes a liquid acid inlet 1 , a liquid acid distributor 6 , a hydrocarbon inlet 2 , a hydrocarbon feed distributor 3 , a mixing element 4 , and an acid hydrocarbon outlet 5 . Wherein, the hydrocarbon feed distributor 3 is located in the middle and upper part of the reactor, including a main feed pipe 3.1, a feed branch pipe 3.2, and a feed riser pipe 3.3. Distributing holes 3.4 are provided on the feed standpipe 3.3. According to the positions of the distribution holes 3.4 and the mixing elements 4, three groups of premixing units 7 and mixing units 8 are arranged inside the reactor, and the two are arranged in a staggered manner to ensure that the distribution holes 3.4 are located in the premixing units and each premixing unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com