Method for preparing alkane fuel with high cetane number by catalyzing plant oil or long-chain fatty acid by Ru catalyst and application thereof

A long-chain fatty acid and high-hexadecane technology is applied in the preparation of biofuels, liquid hydrocarbon mixtures, and biological raw materials. It can solve the problems of poor alkane selectivity, high reaction temperature, and low catalyst activity. The effect of mild reaction conditions and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

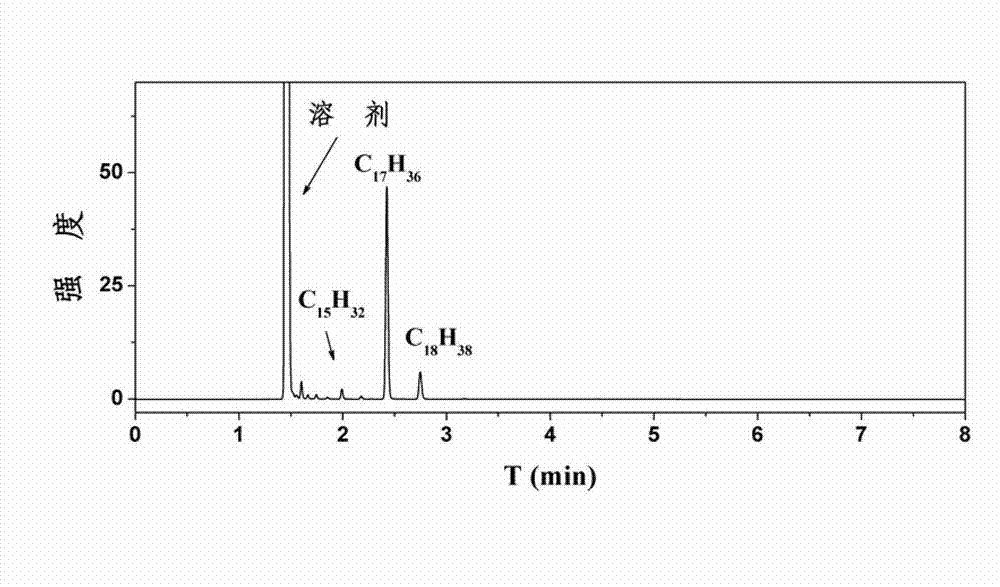

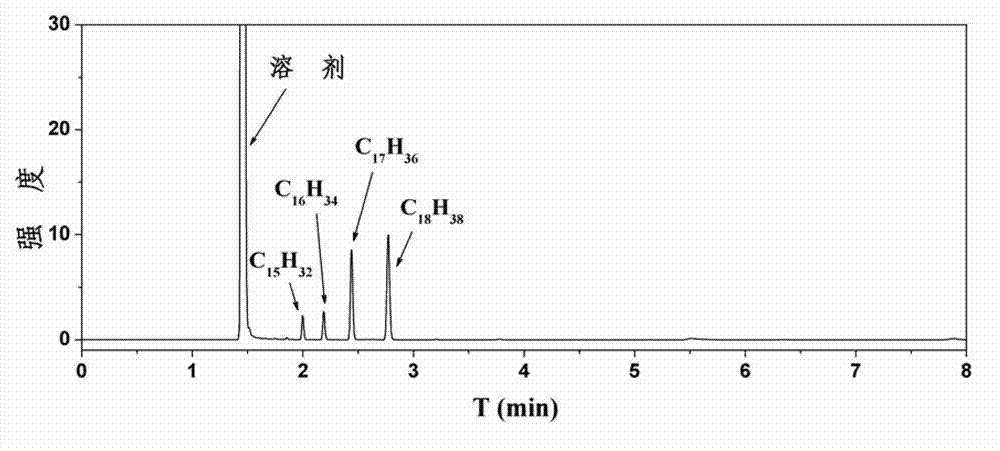

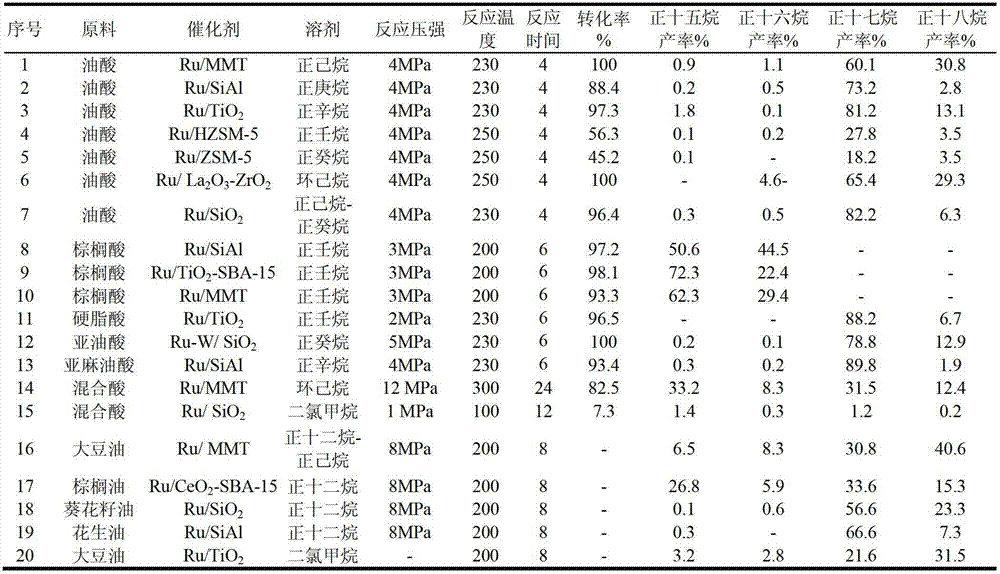

[0030] Weigh 0.2g of long-chain fatty acid and mix it with 20ml of solvent (see Table 1 for details), put it into a 50mL reactor, and then put in 0.1g of catalyst (see Table 1 for details). Replace the air in the kettle with hydrogen for three to four times, and then fill it with hydrogen at a certain pressure to minimize the air content in the kettle, especially the oxygen content, so as to maintain the reducing atmosphere in the kettle. Turn on the stirring device to about 1000 rpm, then heat to a certain temperature (see Table 1 for details) and maintain it for a certain period of time. After the reaction was completed, it was cooled to room temperature, and the liquid product was collected. The liquid product was analyzed for its chemical composition by GC-MS and GC. The results are shown in Table 1 for the results of experiments numbered 1-13.

Embodiment 2

[0032] Weigh 10g of mixed long-chain fatty acids (5g stearic acid + 5g palmitic acid) and mix with 10mL solvent (see Table 1 for details), put it into a 50mL reactor, and then add 5g of catalyst (see Table 1 for details). Replace the air in the kettle with nitrogen for three to four times, and then fill it with hydrogen at a certain pressure to minimize the air content in the kettle, especially the oxygen content, so as to maintain the reducing atmosphere in the kettle. Turn on the stirring device to about 1000 rpm, then heat to a certain temperature (see Table 1 for details) and maintain it for 24 hours. After the reaction was completed, it was cooled to room temperature, and the liquid product was collected. The liquid product was analyzed for its chemical composition by GC-MS and GC. The results are shown in Table 1, the results of experiment No. 14.

Embodiment 3

[0034] Weigh 0.2g mixed long-chain fatty acid (0.1g stearic acid + 0.1g palmitic acid) and mix with 60mL solvent (see Table 1 for details), put it into a 100mL reactor, and then put in 0.1g catalyst (see Table 1 for details ). Replace the air in the kettle with nitrogen for three to four times, and then fill it with hydrogen at a certain pressure to minimize the air content in the kettle, especially the oxygen content, so as to maintain the reducing atmosphere in the kettle. Turn on the stirring device to about 1000 rpm, then heat to a certain temperature (see Table 1 for details) and maintain it for 12 hours. After the reaction was completed, it was cooled to room temperature, and the liquid product was collected. The liquid product was analyzed for its chemical composition by GC-MS and GC. The results are shown in Table 1 for the results of experiment No. 15.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com