Magnesium aluminate spinel castable and method for producing prefabricated brick by using castable

A technology of corundum magnesia-alumina spinel and magnesia-alumina spinel, which is applied in the field of refractory materials, can solve the problems of shortening the service life of corundum spinel prefabricated bricks, achieve short baking time on the line, long service life, and reduce labor intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

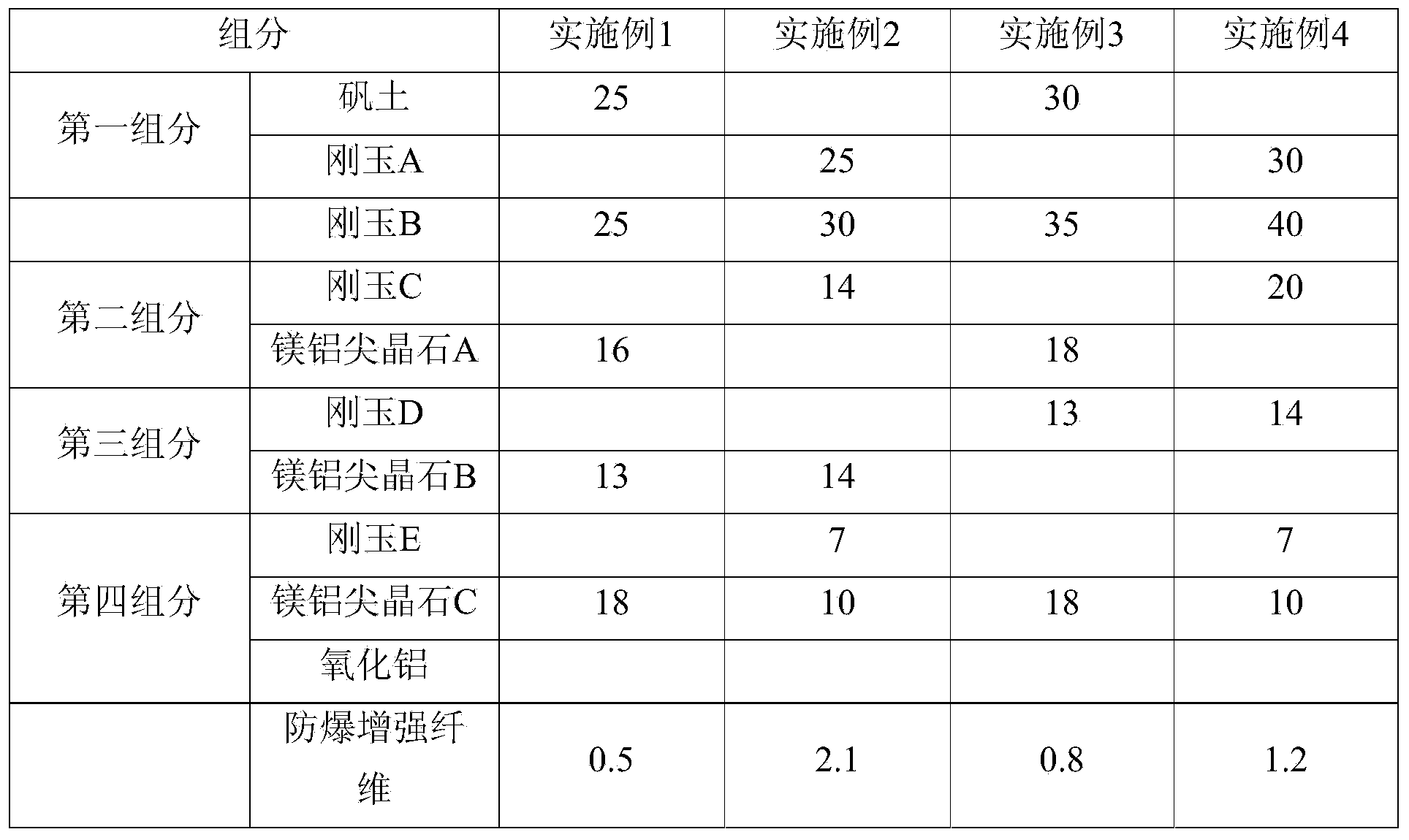

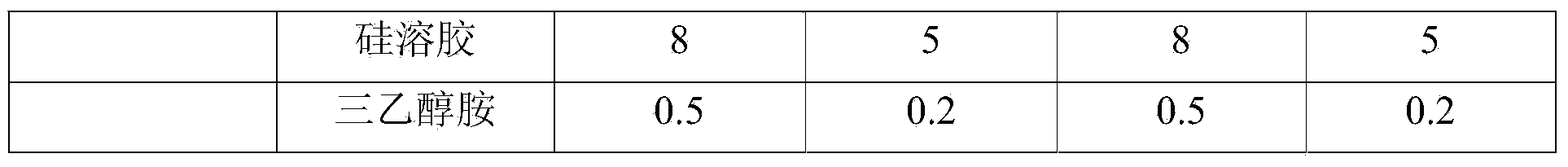

Embodiment 1~6 and comparative example 1~2

[0063] Proportion the raw materials according to the composition of parts by weight listed in Table 1 and Table 2. First, mix the silica sol and the curing agent evenly, then put the rest of the components into the mixer and dry mix them for 1-3 minutes, and then put the pre-mixed Add the silica sol and curing agent into the mixer and stir evenly, pour the evenly stirred material into the corresponding vibrating mold, and vibrate while feeding, so that the pouring material can be evenly filled into the entire mold. After the feeding is completed, continue to vibrate until no air bubbles are discharged. ;

[0064] After standing at room temperature for 24 hours, the mold is demoulded, and the demoulded product is left to stand for another 24 hours, and then baked at 450°C for 48 hours to obtain prefabricated bricks.

[0065] In Table 1 and Table 2, the particle size of corundum A is 25-5mm; the particle size of corundum B is 5-1mm; the particle size of corundum C is 1-0.088mm; ...

Embodiment 1

[0069] The pH of silica sol in embodiment 1, embodiment 2 is 8.5; The pH of silica sol in embodiment 3, embodiment 4 is 9.0; The pH of silica sol in embodiment 5, embodiment 6 is 9.5; Embodiment 7, implementation The pH of silica sol in example 8 is 10.5;

[0070] Na in the silica sol that each embodiment uses 2 The mass fraction of O is not more than 0.7%; SiO 2 The mass fraction of silica sol is 30-40%, the density of silica sol at 20°C is 1.19-1.29kg / L, SiO 2 The particle size of the particle is 8-20nm, and the viscosity at 20°C is ≤20 centipoise.

[0071] The explosion-proof reinforcing fibers in Examples 1 to 4 are mixtures of polypropylene fibers and stainless steel fibers, wherein:

[0072] The weight ratio of polypropylene fiber and stainless steel fiber is 1:10 in embodiment 1 and 2;

Embodiment 3

[0073] The weight ratio of polypropylene fiber and stainless steel fiber in embodiment 3 is 1:3;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com