Method for preparing magnesium aluminate spinel by using secondary aluminum ash

A technology of magnesium aluminum spinel and secondary aluminum, which is applied in the direction of ammonium chloride and ammonium halide, can solve the problems of high product impurities and poor performance, and achieve high alumina content, low impurity content and fast reaction speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

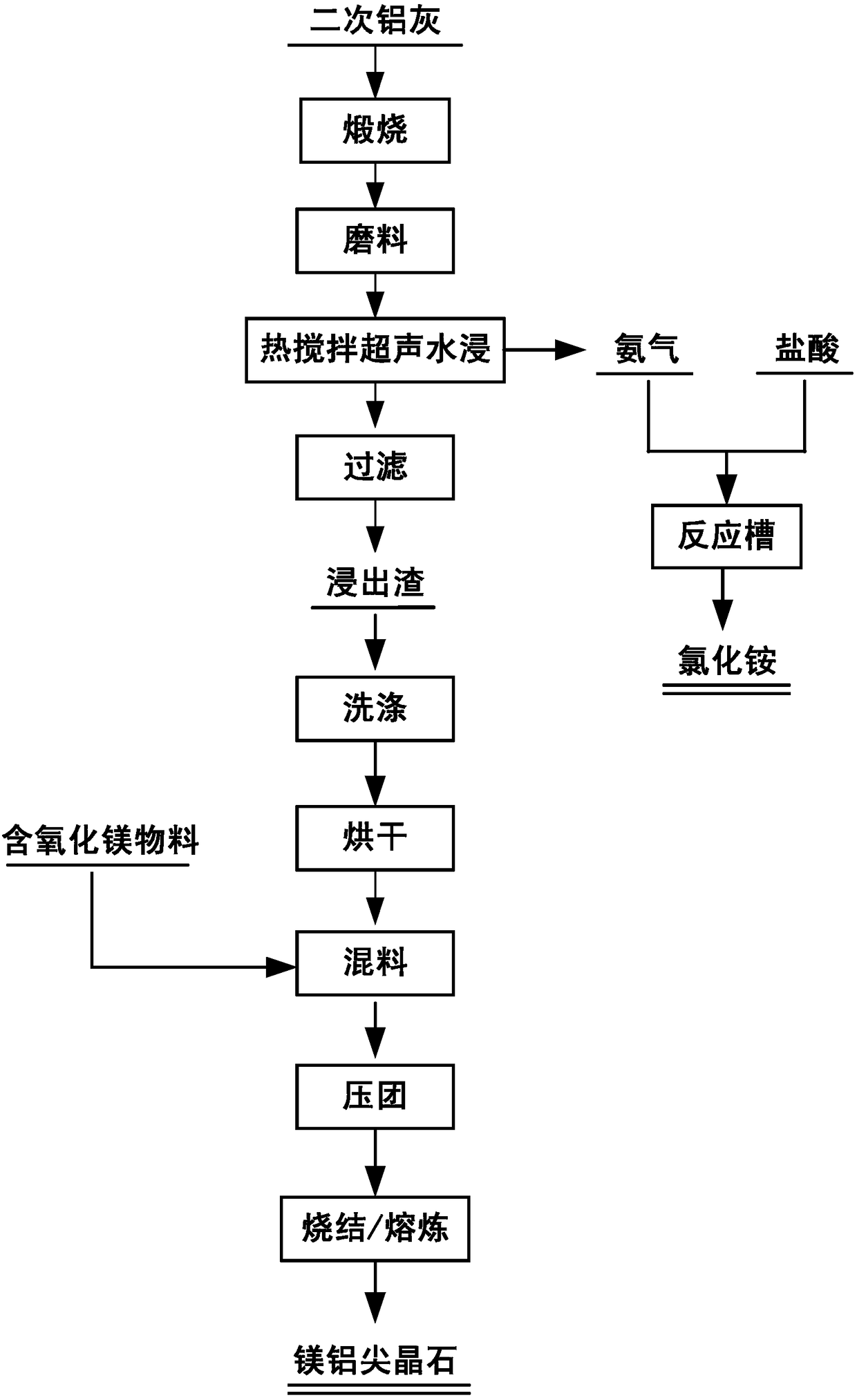

[0034] Process such as figure 1 shown;

[0035] Prepare secondary aluminum ash as a raw material; said secondary aluminum ash is the secondary aluminum ash formed after the aluminum ash utilizes the melting and casting process to extract aluminum, and the main components contain Al 6% by mass percentage, Al 2 o 3 59.5%, AlN 26%, MgO 6%, impurities 3.5%;

[0036] Calcinate the secondary aluminum ash at 1000°C for 2 hours, cool to room temperature and then ball mill until the particle size is ≤106 μm to make secondary aluminum ash fine powder;

[0037] Add the secondary aluminum ash fine powder into water, the solid-to-liquid ratio of the secondary aluminum ash fine powder to water is 100g / L; then, at a temperature of 90°C and stirring, apply ultrasonic waves for water immersion to make the secondary aluminum ash The aluminum nitride in the fine powder material undergoes a hydrolysis reaction; the alkaline gas ammonia gas generated during the water immersion process is disch...

Embodiment 2

[0043] Method is with embodiment 1, and difference is:

[0044] (1) Secondary aluminum ash, the main component contains Al 10% by mass percentage, Al 2 o 3 60%, AlN 22%, MgO 6%, impurity 2%;

[0045] (2) During water immersion, the stirring speed is 800r / min, and the ultrasonic frequency is 100kHz; after the leaching residue is washed and dried, it is mixed and ground with magnesium oxide (particle size ≤ 106 μm) made by calcining magnesium hydroxide;

[0046] (3) The temperature of high-temperature sintering is 1700° C., and the time is 4 hours;

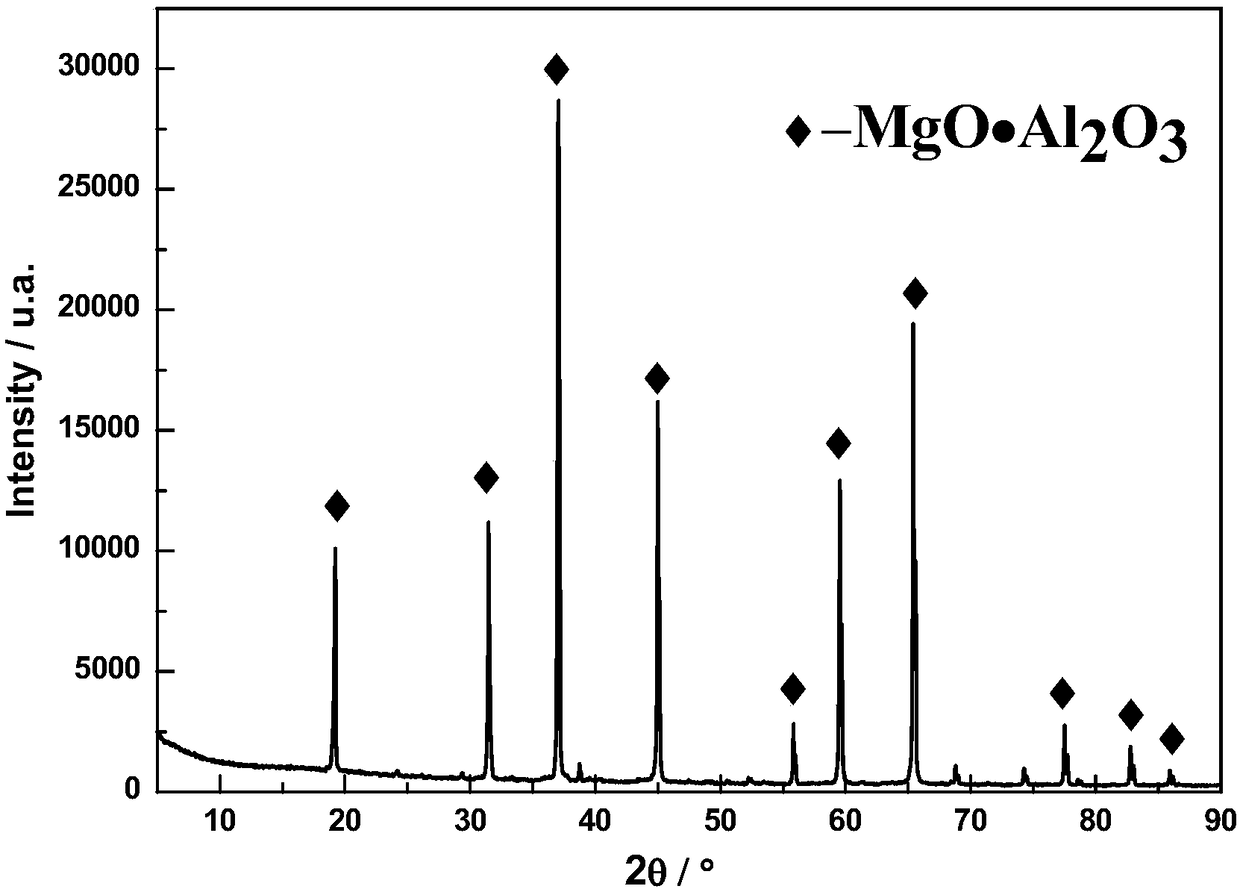

[0047] Magnesium aluminum spinel contains Al by mass percentage 2 o 3 70.3%, MgO 27.9%, bulk density 3.29g / cm 3 .

Embodiment 3

[0049] Method is with embodiment 1, and difference is:

[0050] (1) Secondary aluminum ash, the main component contains Al by mass percentage 2 o 3 55%, AlN 12%, MgO 20%, impurities 3%;

[0051] (2) The pellets are smelted in an electric arc furnace (at a temperature exceeding 1700° C.) to produce magnesia-aluminum spinel; the time for smelting in the electric arc furnace is 2 hours;

[0052] Magnesium aluminum spinel contains Al by mass percentage 2 o 3 71.5%, MgO 27.1%, bulk density 3.42g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com