Method for preparing superfine mesoporous magnesium aluminate spinel

A magnesia-aluminum spinel, mesoporous technology, applied in the preparation of alkaline earth metal aluminate/alumina/aluminum hydroxide, magnesium aluminate, alumina/aluminum hydroxide, etc., can solve the problem of nano-magnesium-aluminum spinel Rarely seen and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1-4

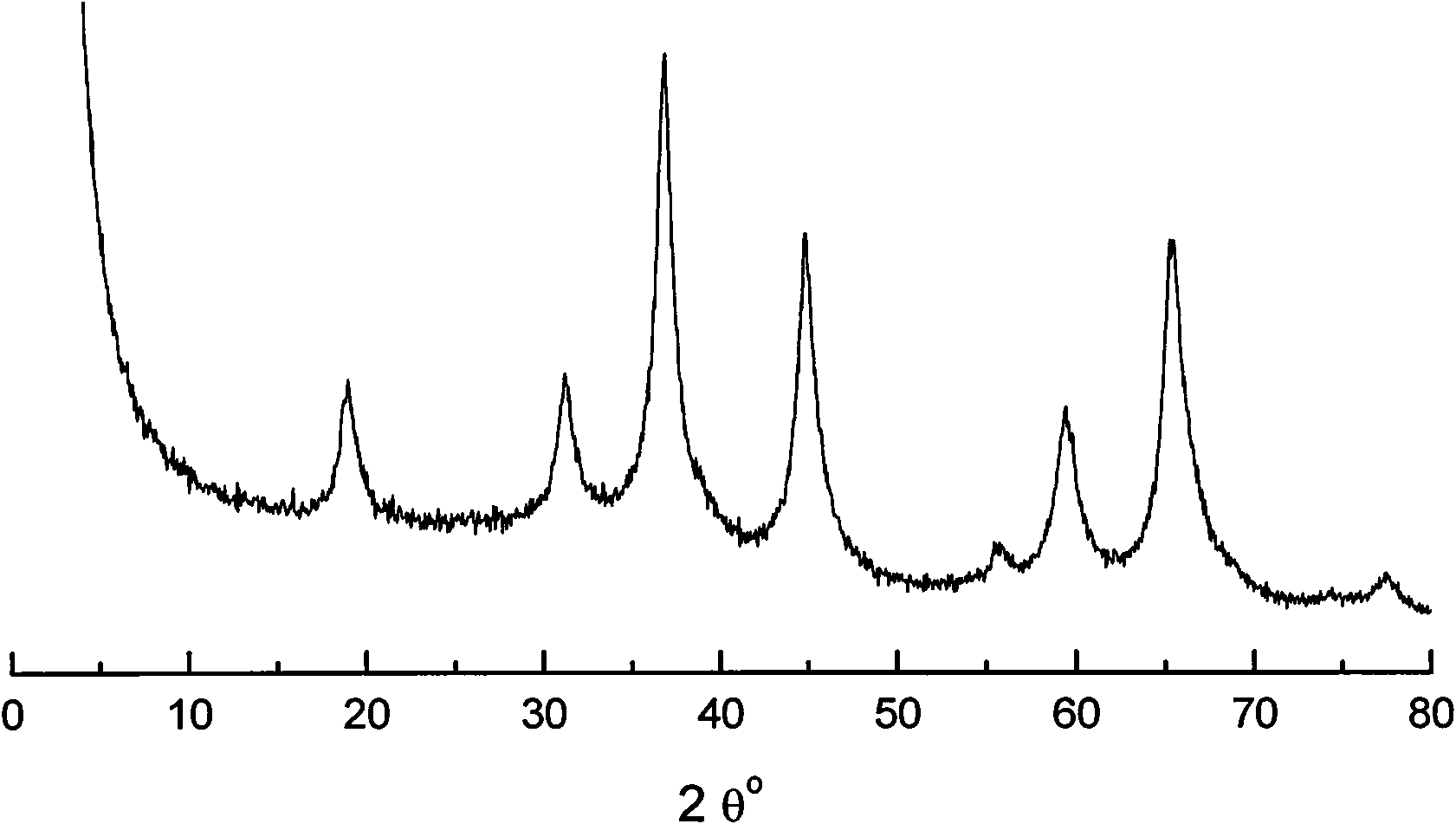

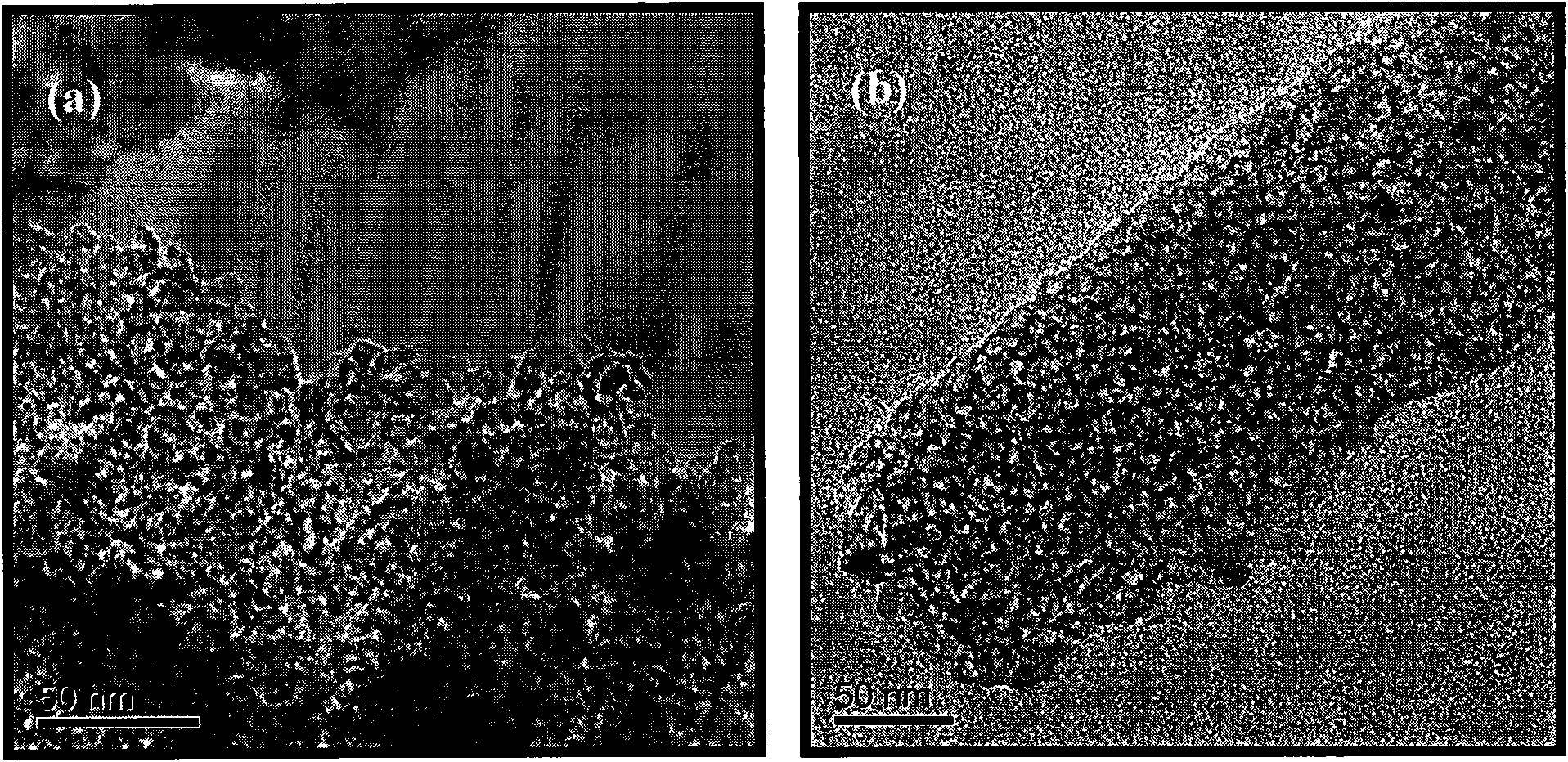

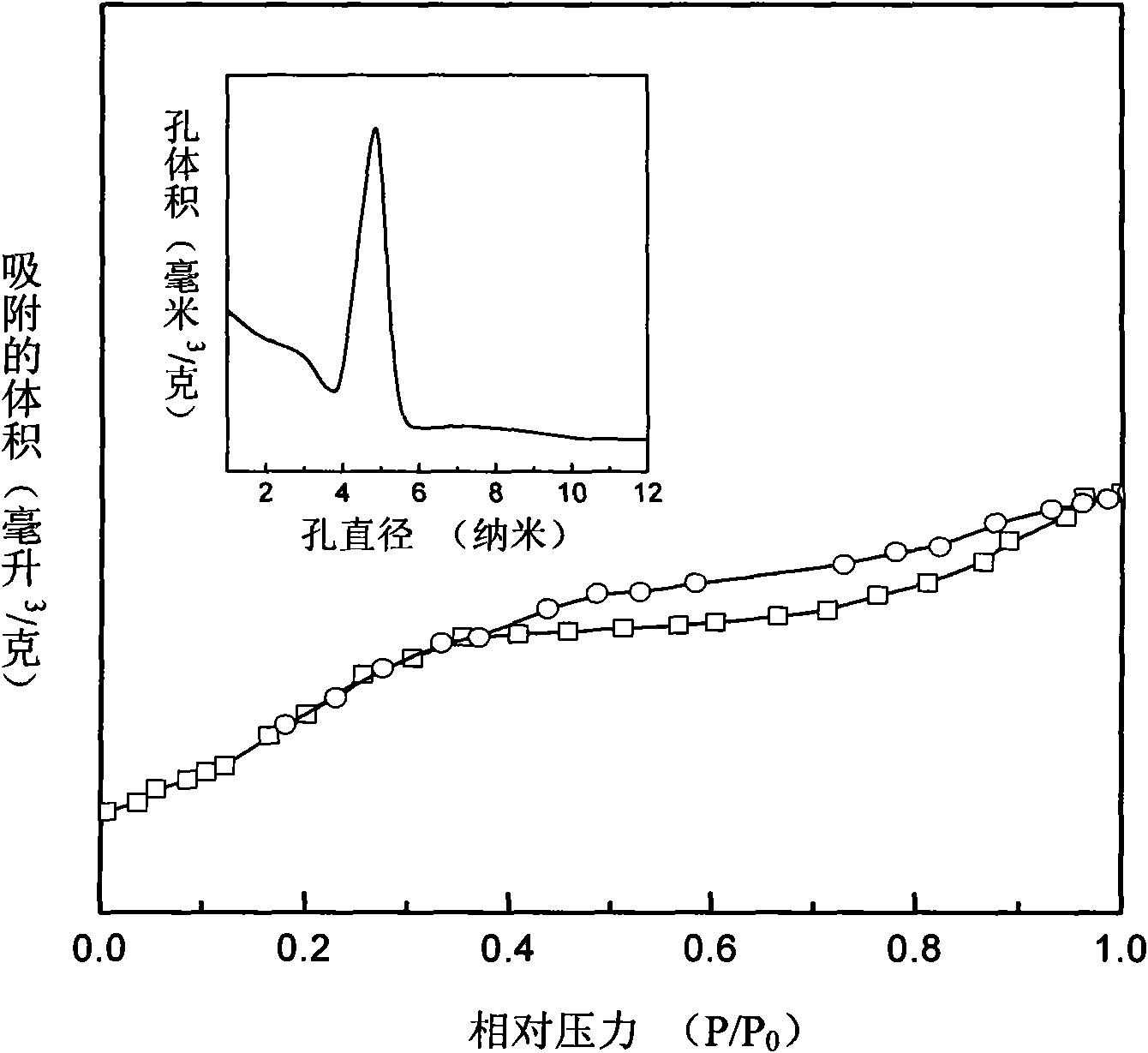

[0039] Examples 1-4 illustrate the preparation of magnesium aluminum spinel with different aluminum sources, magnesium sources and preparation conditions by adopting the method provided by the present invention. The formula used and the properties of the synthesized magnesium aluminum spinel are shown in Table 1. The specific preparation method of magnesium aluminum spinel is as follows: (1) Weigh a certain amount of aluminum source and magnesium source compound, dissolve in 50 milliliters of deionized water to make mixed solution I; (2) under continuous and rapid stirring conditions 216 milliliters of ammoniacal liquor of 25% by weight is added dropwise in mixed solution I; And add 0.36 gram of hexadecyltrimethylammonium bromide, make mixed solution II; Each component mol ratio is about in the mixture, Al: Mg:OH - : Surfactant: H 2 O=2: 1: 3: 0.1: 10; (3) after the dropwise addition, the mixed solution II continued to stir for a certain period of time at room temperature, a...

example 5-8

[0044] Examples 5-8 illustrate the preparation of magnesium aluminum spinel with different surfactants, lyes and preparation conditions by using the method provided by the present invention. The formula used and the properties of the synthesized magnesium aluminum spinel are shown in Table 2. The specific preparation method of magnesium aluminum spinel is as follows: (1) Weigh a certain amount of aluminum source and magnesium source compound, dissolve in 50 milliliters of deionized water to make mixed solution I; (2) under continuous and rapid stirring conditions , a certain amount of lye is added dropwise to the mixed solution I; and an appropriate amount of surfactant is added to make the mixed solution II; the molar ratio of each component in the mixture is about, Al: Mg: OH - : Surfactant: H 2 O=2: 1: 3: 0.1: 10; (3) after the dropwise addition, the mixed solution II continued to stir for 1 hour at room temperature, and left to age for 8 hours; (4) the aged mixture was ch...

example 9-12

[0048] Examples 9-12 illustrate the preparation of magnesium-aluminum spinel with different raw material ratios and preparation conditions by using the method provided by the present invention. The formula used and the properties of the synthesized magnesium aluminum spinel are shown in Table 3. The specific preparation method of magnesium aluminum spinel is as follows: (1) Weigh a certain amount of aluminum source and magnesium source compound, dissolve in 50 milliliters of deionized water to make mixed solution I; (2) under continuous and rapid stirring conditions 216 milliliters of ammoniacal liquor of 25% by weight is added dropwise in mixed solution I; And add 0.36 gram of hexadecyltrimethylammonium bromide, make mixed solution II; Each component mol ratio is about in the mixture, Al: Mg:OH - : Surfactant: H 2 O=2: 1: 3: 0.1: 10; (3) After the dropwise addition, the mixed solution II continued to be stirred at room temperature for 0.5 hours, and left to age for 4 hours;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com