Slag-corrosion-resistant magnesite-spinel brick and preparation method thereof

A magnesia spinel and magnesia-aluminum spinel technology, applied in the field of anti-slag erosion magnesia spinel brick and its preparation, can solve the problems of pollution, air pollution, health hazards, etc., and achieve increased viscosity and thermal shock stability. Improved performance and improved thermal shock stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

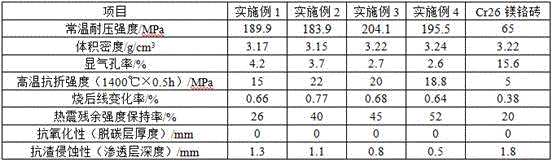

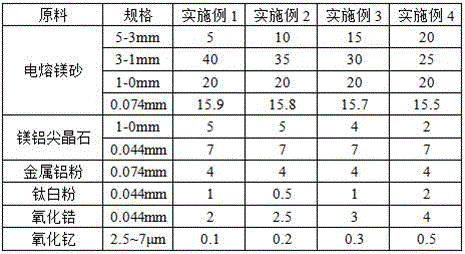

[0044] Embodiment 1~4 gained product and the Cr26 (being Cr 2 o 3 mass percentage) magnesia-chrome bricks, the comparative test results are shown in Table 2, wherein, the carbon-containing admixture used in Example 1 is thermoplastic phenolic resin, and the dosage is 3.5% of the total components of magnesia spinel bricks. 2. The carbon-containing admixture used is modified asphalt resin, and the dosage is 3.5% of the total components of the magnesia spinel brick. The carbon-containing admixture used in Example 3 is thermosetting phenolic resin and modified asphalt resin, and the dosage is 3.5% of the total amount of each component of magnesia spinel brick, the carbon-containing admixture adopted in embodiment 4 is thermosetting phenolic resin, thermoplastic phenolic resin and modified pitch resin, and the amount is 3.5% of the total amount of each component of magnesia spinel brick 3.5%.

[0045] Table 2 Comparison of performance indicators between the products of Examples 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com