Light-weight refractory castable for blast furnace swing chute and preparation method thereof

A technology of refractory castables and swing chutes, which is applied in the field of refractory materials and can solve the problems of high-temperature melting of steel fibers and unfavorable material properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

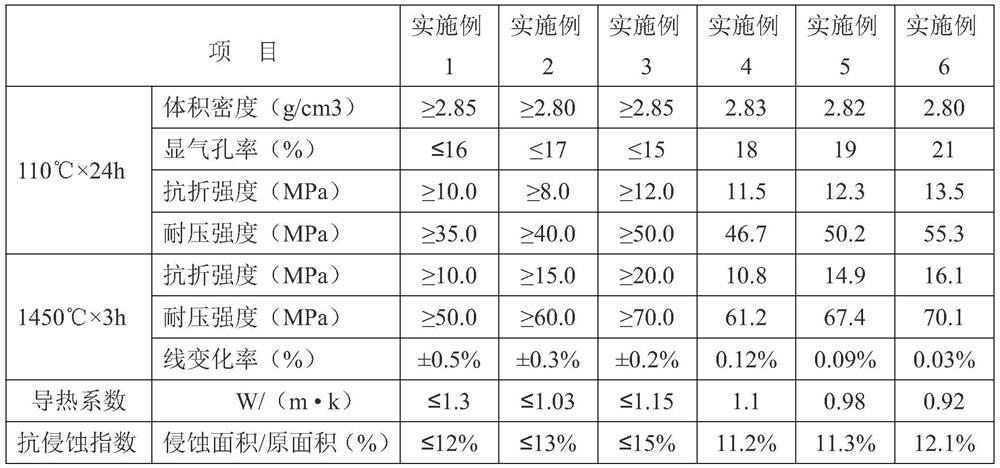

Examples

Embodiment 1

[0044]50-55 parts of microporous corundum particles, 13-15 parts of fused dense corundum particles, 13-15 parts of silicon carbide, 1-2 parts of cement, 2-3 parts of silicon micropowder, 1-2 parts of carbon black, activated alumina Put 8-10 parts of fine powder, 2-3 parts of antioxidant, 1-2 parts of composite anti-explosion agent, and 0.2-0.3 parts of water reducer into a forced mixer and stir for 10-15 minutes, so that all materials are fully mixed evenly to obtain a lightweight blast furnace Refractory castables for swing chutes.

Embodiment 2

[0046] 55-60 parts of microporous corundum particles, 12-13 parts of plate-shaped corundum particles, 12-13 parts of silicon carbide, 2-3 parts of cement, 1-2 parts of silicon micropowder, 2-3 parts of carbon black, activated alumina micropowder Put 7-9 parts, 1-2 parts of antioxidant, 2-3 parts of composite explosion-proof agent, and 0.2-0.3 parts of water reducing agent into the forced mixer and stir for 10-15 minutes, so that all materials are fully mixed evenly to obtain lightweight blast furnace swing Refractory castables for chutes.

Embodiment 3

[0048] 60-65 parts of microporous corundum particles, 10-12 parts of corundum particles, 10-12 parts of silicon carbide, 1-2 parts of cement, 2-3 parts of silicon micropowder, 1-2 parts of carbon black, and 6-2 parts of activated alumina micropowder 8 parts, 2 to 3 parts of antioxidant, 1 to 2 parts of composite explosion-proof agent, and 0.1 to 0.2 parts of water reducer are put into a forced mixer and stirred for 10 to 15 minutes, so that all materials are fully mixed evenly to obtain a lightweight blast furnace swing chute Refractory castables.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com