A low-cost long-service-lifetime ceramic saggar and a preparing method thereof

A long-life, low-cost technology, applied in the field of refractory kiln furniture preparation, can solve the problems of high cost and short service life, and achieve good thermal shock resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

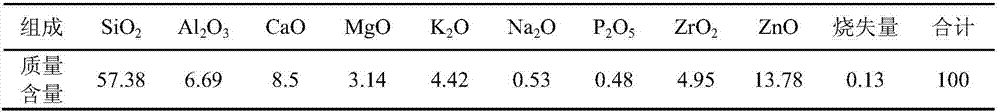

[0023] A low-cost and long-life ceramic sagger and a preparation method thereof, comprising the steps of:

[0024] 1) Raw material ratio: talc, bauxite, magnesia-aluminum spinel and cordierite are respectively ball-milled with a ball mill, wherein the magnesia-alumina spinel is divided into two parts for ball milling respectively, one part of which is ball-milled for 0.5h and passed through a 60-mesh sieve, and the other A portion of the raw material is milled for 1.5 hours and passed through a 100-mesh sieve, and other raw materials are ball-milled for 5 hours and passed through a 200-mesh sieve, and then the ingredients are formulated according to the following mass percentages: talc 20%, bauxite 15%, 60-mesh magnesium aluminum spinel 35%, 100 mesh magnesium aluminum spinel 15%, cordierite 15%;

[0025] 2) Preparation of the ceramic sagger green body: mix the raw materials prepared in step 1) in a kneader to obtain a mixed powder, then add a water-soluble binder and water to...

Embodiment 2

[0035] A low-cost and long-life ceramic sagger and a preparation method thereof, comprising the steps of:

[0036] 1) Raw material ratio: talc, bauxite, magnesia-alumina spinel and cordierite are respectively ball-milled with a ball mill, wherein the magnesia-alumina spinel is divided into two parts and ball-milled respectively, one of which is ball-milled for 1 hour and passed through a 65-mesh sieve, and the other After ball milling for 2 hours, pass through a 120 mesh sieve, and other raw materials pass through a 350 mesh sieve after ball milling for 10 hours, and then mix according to the following mass percentages: talc 25%, bauxite 20%, 65 mesh magnesia spinel 35%, 120 mesh Magnesium aluminum spinel 15%, cordierite 5%;

[0037]2) Preparation of the ceramic sagger green body: put the raw materials prepared in step 1) in a kneader and mix them to obtain a mixed powder, then add a water-soluble binder and water to the mixed powder, and continue mixing for 50 minutes to obta...

Embodiment 3

[0044] A low-cost and long-life ceramic sagger and a preparation method thereof, comprising the steps of:

[0045] 1) Raw material ratio: talc, bauxite, magnesia-alumina spinel and cordierite are respectively ball-milled with a ball mill, wherein magnesia-alumina spinel is divided into two parts and ball-milled respectively, one part of which is ball-milled for 0.6h and passed through a 60-mesh sieve, and the other A portion of the raw material is milled for 1.6 hours and passed through a 100-mesh sieve, and other raw materials are ball-milled for 8 hours and passed through a 350-mesh sieve, and then the ingredients are formulated according to the following mass percentages: 25% talc, 15% bauxite, 25% 60-mesh magnesium aluminum spinel, 100 mesh magnesium aluminum spinel 30%, cordierite 5%.

[0046] 2) Preparation of the ceramic sagger green body: mix the raw materials prepared in step 1) in a kneader to obtain a mixed powder, then add a water-soluble binder and water to the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com